Mixed material pilling, barrel polishing and drying device

A drum polishing and drying device technology, which is applied in the direction of making medicines into special physical or ingestible devices, can solve the problems of lack of equipment volume in the connection, occupy a large production space, waste production resources, etc., and solve the problem of installation and debugging Long time, reduce equipment cost, save time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

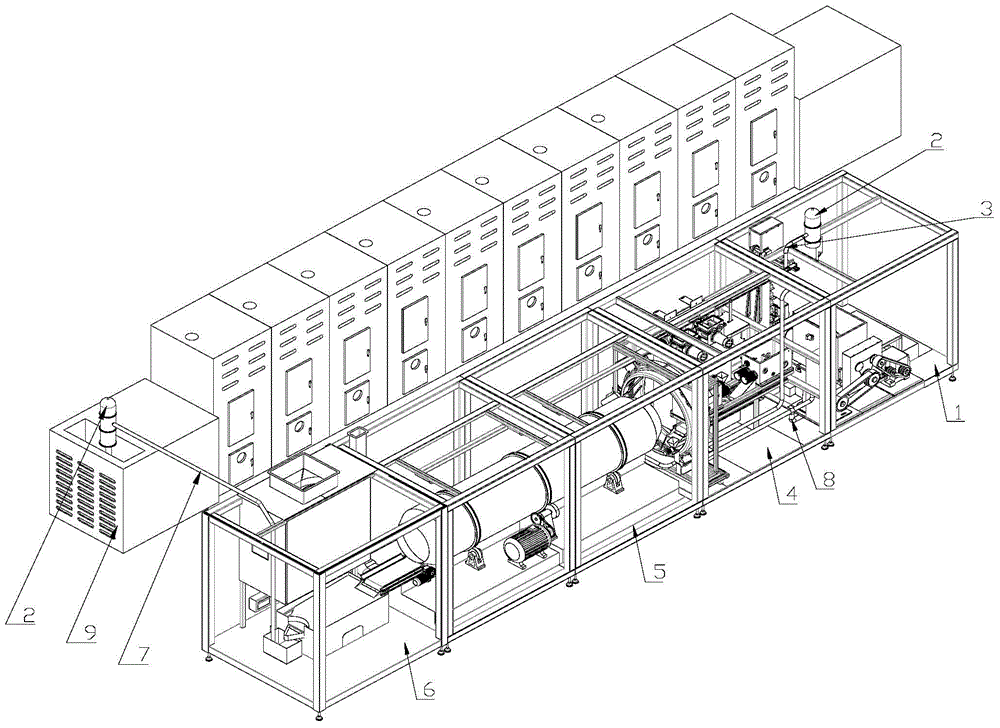

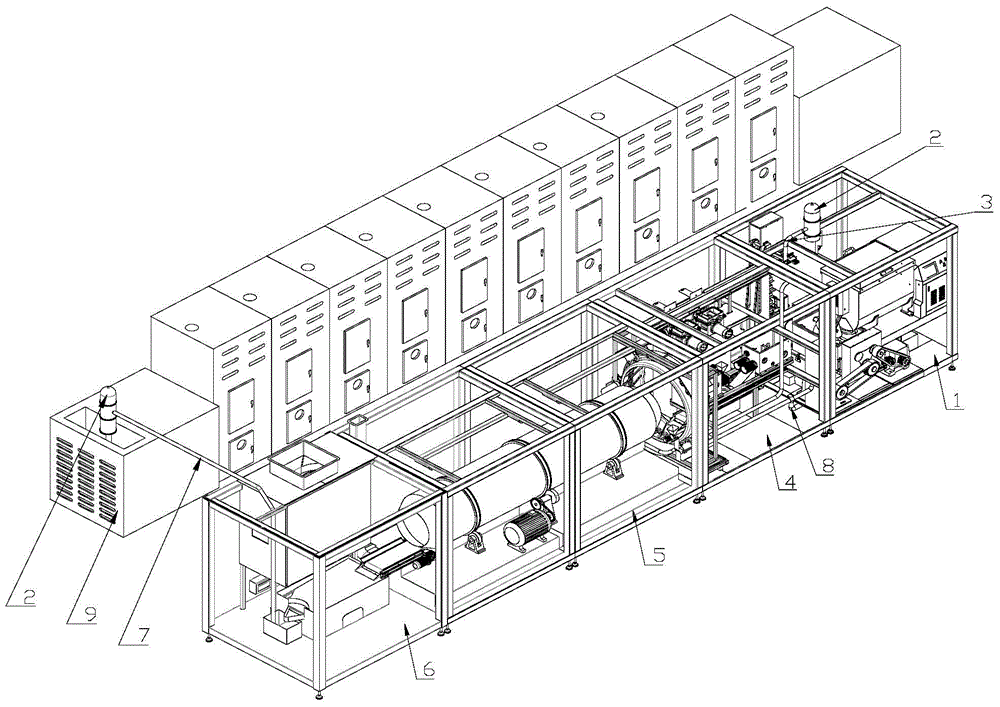

[0027] Example 1, see figure 1 , a drum polishing and drying device for mixing and pelletizing, comprising a mixing and refining module 1, a pelletizing module 4, a polishing module 5, a pellet selecting module 6 and a microwave drying module 9 connected in sequence.

[0028] See Figure 7 , the microwave drying, 9 includes a microwave drying box 9-1 and a microwave control system 9-2, the collection box 6-3 is provided with a vacuum pumping system 6-4, and the outlet of the microwave drying Above the inlet of box 9-1.

[0029] Described microwave drying structure 9 can be the conventional microwave equipment that microwave frequency is 2450MHZ, see Figure 7 , it can also be a microwave with a frequency of 915MHZ, which has a stronger microwave penetration capability, see Figure 9 shown, it can also be microwave equipment with a vacuum cavity, see Figure 10 .

[0030] All the other are identical in structure with embodiment 1.

Embodiment 2

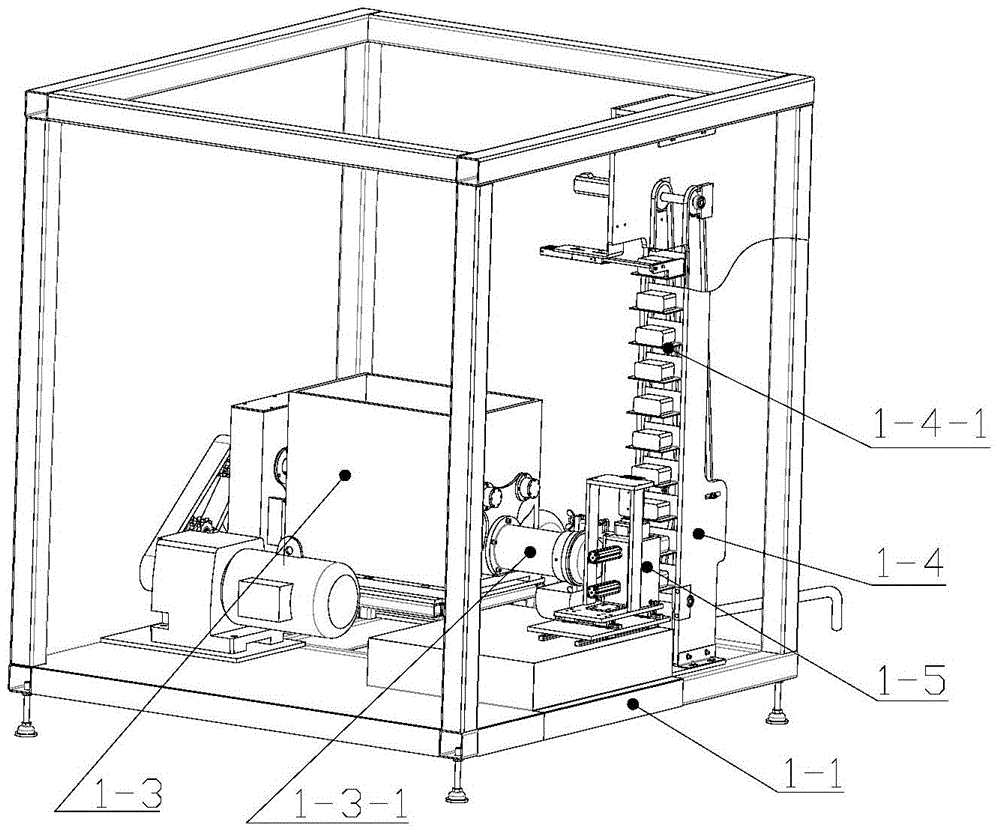

[0031] Embodiment 2, see Fig. 3, described mixing compounding medicine module 1 comprises that the module base 1-1 is provided with double paddle mixing medicine refining compound machine 1-3; The outlet 1 of double paddle mixing medicine refining compound machine 1-3 -3-1 is connected to the forming mold 1-5, and the discharge end of the forming mold 1-5 is an elevator lifting device 1-4; the elevator lifting device 1-4 is provided with a feeding chain plate 1-4-1.

[0032] All the other are identical in structure with embodiment 1.

Embodiment 3

[0033] Example 3, see Figure 4 , the pellet making module 4 includes a pellet making machine 4-4 on the module base 4-3, a feeding flat conveyor belt 4-1 is arranged above the pill making machine 4-4, and a feeding flat conveyor belt 4-1 is arranged on the feeding flat conveyor The feeding end of the belt 4-1 is located below the feeding chain plate 1-4-1 of the elevator lifting device 1-4; a pushing cylinder 4-2 is provided on the feeding flat conveyor belt 4-1; The bottom of machine 4-4 is provided with discharging flat conveyor belt 4-5, and its end is provided with waterwheel type hoist 4-6.

[0034] All the other are identical in structure with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com