Integrated treating method for plastic pelletization waste gas

A treatment method and oxidation treatment technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of polluting the ecological environment, surrounding residents, health and safety hazards, etc., to reduce energy consumption and save land. , good oxidative decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

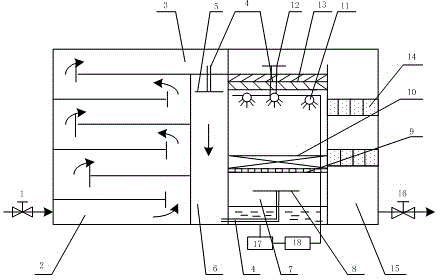

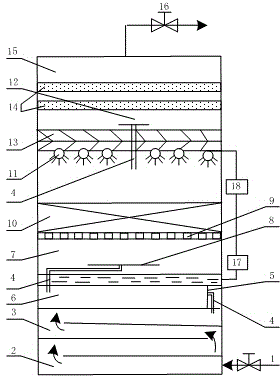

[0018] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings, but the implementation and protection of the present invention are not limited to this.

[0019] An integrated plastic granulation waste gas treatment method, which uses ozone to fully contact the waste gas to oxidize the waste gas. The oxidized gas is then degraded by ultraviolet light, and the ultraviolet degraded gas is then treated with acid The mist purification tower and alkaline absorption liquid are purified, and finally activated carbon adsorption treatment.

[0020] The method of this example passes figure 1 or figure 2 The processing device used in this example shown in accordance with the waste gas treatment process includes an oxidation tower 3, an acid mist purification tower 7 and an adsorption tower 15. The three towers are integrated; there is an exhaust gas inlet 1 at the bottom of the oxidation tower, and the oxidation to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com