A kind of preparation method and application of hydrophilic methacrylamide polymer monolithic column

A technology of methacrylamide and polymers, which is applied in the field of preparation of monolithic columns of hydrophilic methacrylamide polymers, achieving good application prospects, fast and efficient separation, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

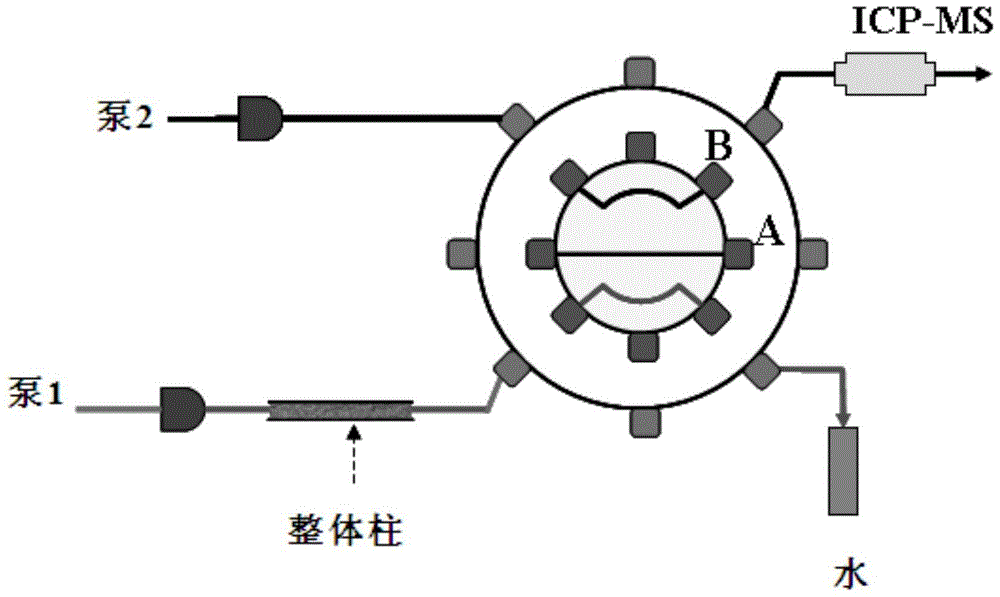

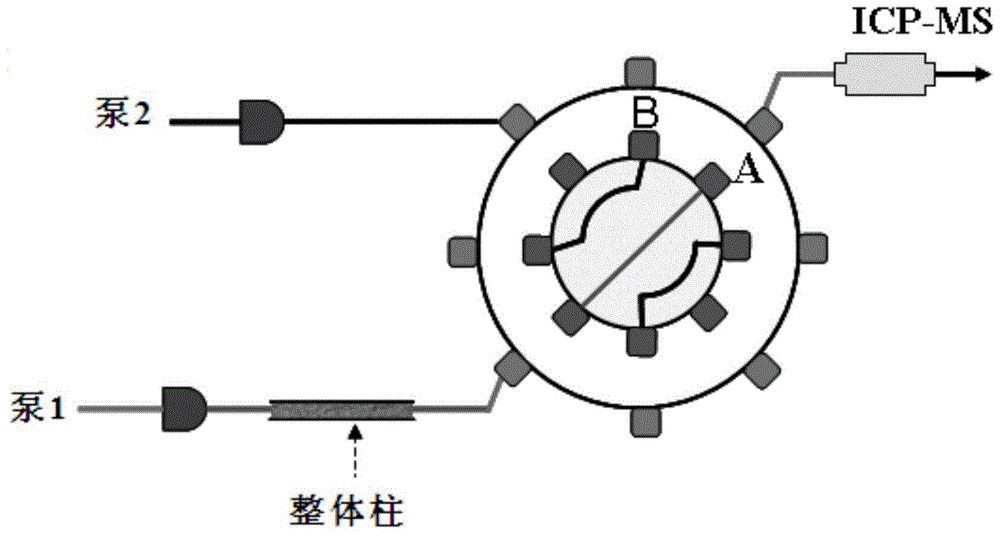

Method used

Image

Examples

Embodiment l

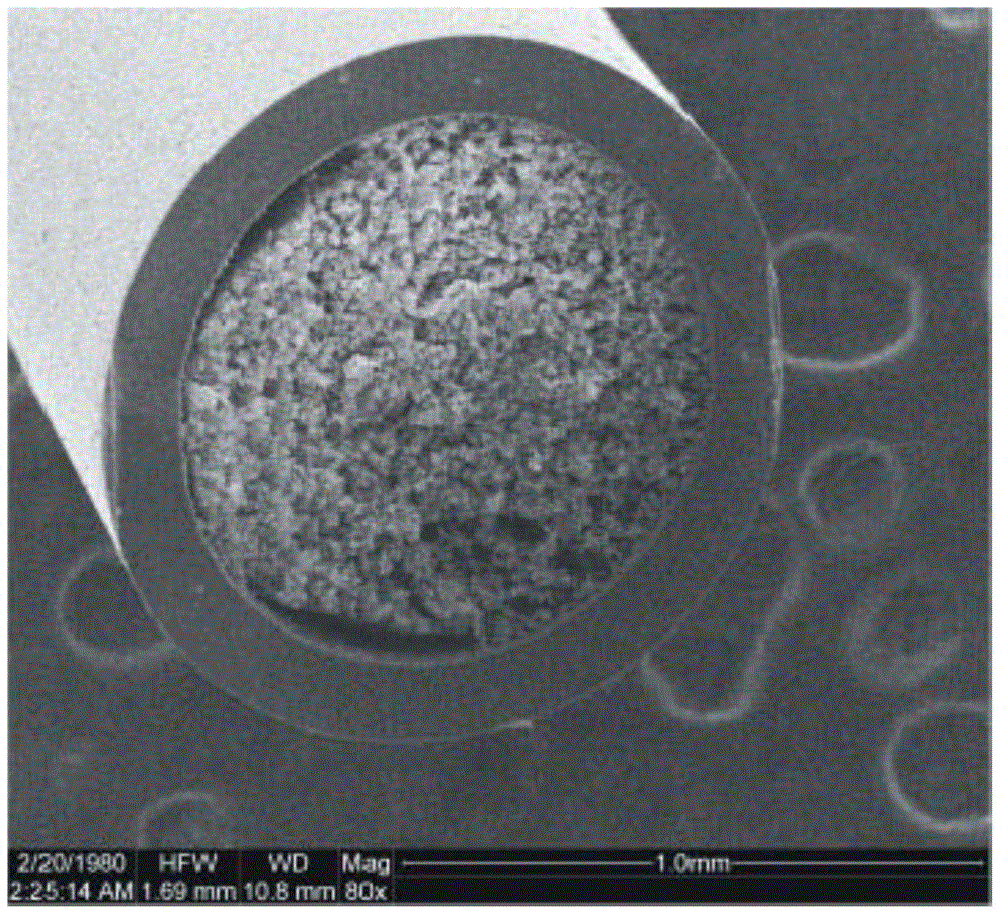

[0055] 1. Preparation of methacrylamide polymer capillary monolithic column

[0056] The synthesis steps of the methacrylamide polymer monolithic column are as follows:

[0057] (1) Activation process of the capillary: Rinse the glass capillary (10 cm×1 mm) with ultrapure water for 10 min, 1.0 mol L -1 Rinse with NaOH for 2h, rinse with ultrapure water for 30min, 1.0mol L -1 Rinse with HCl for 2 hours, rinse with ultrapure water to neutrality, and dry at 160°C for 5 hours under nitrogen protection; then inject ethanol / methacryloxytrimethoxysilane (γ-MAPS) with a volume ratio of 1:1 The solution bonds double bonds to the inner wall of the capillary.

[0058] (2) Preparation of hydrophilic methacrylamide polymer monolithic column by in situ synthesis: 110 mg of AA, 120 mg of Bis, 0.08 mL of 4-VP, 0.6 mL of dodecanol, AIBN were dissolved in 0.75 mL In DMSO, a mixed solution is formed, and the content of the AIBN in the mixed solution is 1wt%. After ultrasonication for 10 min,...

Embodiment 2

[0083] The synthesis steps of the methacrylamide polymer monolithic column are as follows:

[0084] (1) Activation process of the capillary: Rinse the glass capillary (10 cm×1 mm) with ultrapure water for 10 min, 1.0 mol L -1 Rinse with NaOH for 2h, rinse with ultrapure water for 30min, 1.0mol L -1 Rinse with HCl for 2 hours, rinse with ultrapure water to neutrality, and dry at 160°C for 5 hours under nitrogen protection; then inject ethanol / methacryloxytrimethoxysilane (γ-MAPS) with a volume ratio of 1:1 The solution bonds double bonds to the inner wall of the capillary.

[0085] (2) Preparation of hydrophilic methacrylamide polymer monolithic column by in situ synthesis: 110 mg of AA, 120 mg of Bis, 0.08 mL of 4-VP, 0.6 mL of dodecanol, AIBN were dissolved in 0.75 mL In DMSO, a mixed solution is formed, and the content of the AIBN in the mixed solution is 1wt%. After ultrasonication for 10 min, inject into the activated capillary in step (1), then seal both ends with a si...

Embodiment 3

[0087] The synthesis steps of the methacrylamide polymer monolithic column are as follows:

[0088] (1) Activation process of the capillary: Rinse the glass capillary (10 cm×1 mm) with ultrapure water for 10 min, 1.0 mol L -1 Rinse with NaOH for 2h, rinse with ultrapure water for 30min, 1.0mol L -1 Rinse with HCl for 2 hours, rinse with ultrapure water to neutrality, and dry at 160°C for 5 hours under nitrogen protection; then inject ethanol / methacryloxytrimethoxysilane (γ-MAPS) with a volume ratio of 1:1 The solution bonds double bonds to the inner wall of the capillary.

[0089] (2) Preparation of hydrophilic methacrylamide polymer monolithic column by in situ synthesis: 110 mg of AA, 120 mg of Bis, 0.08 mL of 4-VP, 0.6 mL of dodecanol, AIBN were dissolved in 0.75 mL In DMSO, a mixed solution is formed, and the content of the AIBN in the mixed solution is 1wt%. After ultrasonication for 10 min, inject into the activated capillary in step (1), then seal both ends with a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com