Regeneration method of catalyst for synthesizing isopropylbenzene

A propylbenzene catalyst and a catalyst technology are applied in the field of catalysis and can solve the problems of affecting catalyst activity and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

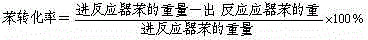

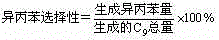

[0026] Take the freshly synthesized cumene catalyst (catalyst X0), when the molar ratio of benzene to benzene is 2.0, and the space velocity of propylene is 1.0h -1 , and the reaction temperature was 170°C, put it into a fixed-bed reactor with a catalyst loading of 40g, and continue the reaction for 1000h. At this time, the activity of the catalyst decreased, and this batch of catalyst was unloaded, which was recorded as deactivated catalyst Y.

[0027]

Embodiment 2

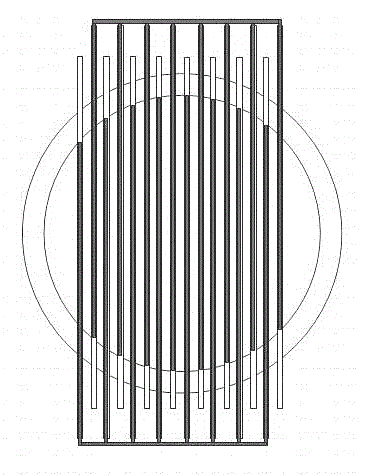

[0029] A fork-type dielectric barrier discharge reactor (consisting of needle-shaped electrodes intersecting, the dielectric material is quartz, see figure 1 ), apply a pulse voltage of 20kV, the frequency of the voltage is 1000Hz, the rising edge time is 200ns, and the pulse width is 400ns. Get 5 grams of deactivated catalyst Y for synthesizing cumene and place it in the discharge area of the dielectric barrier discharge reactor, and place it evenly, and feed air into the device, the air flow rate is 1000ml / min, turn on the power switch, and process for 30min , the regenerated catalyst A1 was obtained, and the catalyst activity after being used for 1000 hours and regenerated twice by the same method was designated as A3.

[0030]

Embodiment 3

[0032] A needle-plate dielectric barrier discharge reactor (composed of needle electrodes and plate electrodes, and ordinary glass as the dielectric material) is used to apply a pulse voltage of 5kV. The frequency of the voltage is 1000Hz, the rising edge time is 200ns, and the pulse width is 400ns. Get 5 grams of deactivated catalyst Y for synthesizing cumene and place it in the discharge area of the dielectric barrier discharge reactor, and place it evenly, and feed air into the device, the air flow rate is 1000ml / min, turn on the power switch, and process for 3min , the regenerated catalyst B1 was obtained, and the catalyst activity after being used for 1000 hours and regenerated twice by the same method was designated as B3.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com