End milling cutter

A technology of end mills and cutting parts, which is applied in the field of end mills, can solve the problems of poor stress environment, easy slipping and loosening of tool blades, waste of materials, etc., to achieve firm clamping, not easy to loosen, and suppress high-frequency vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

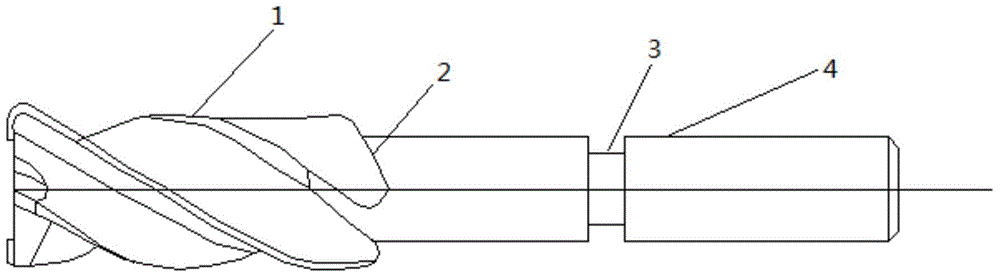

[0010] refer to figure 1 , a kind of end milling cutter, comprises cutting part and shank part, and cutting part is provided with helical cutting edge, and described cutting edge is curved surface structure, and the edge part on cutting edge is set to the structure of unequal helix angle; Said cutting The surface is coated with a layer of aluminum oxide titanium coating.

[0011] The middle part of the handle is provided with an annular slot.

[0012] The outer diameter of the shank is smaller than the outer diameter of the cutting part.

[0013] The invention adopts the curved cutting edge and unequal helix angle which can suppress the height difference of the vertical surface processing, effectively suppresses the high-frequency vibration, and improves the stability when the tool is processed; the middle part of the shank is provided with an annular slot, which is convenient for the chuck to hold the tool , and the clamping is relatively firm and not easy to loosen; the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com