Working condition monitoring device of hydrostatic guideway

A static pressure guide rail and monitoring device technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem of not being able to monitor the real-time floating state data of the static pressure guide rail, equipment safety, precise operation, and difficulty in accurately controlling the supply Oil flow and other issues, to achieve the effect of high reliability and adaptability, compact structure, excellent wide temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

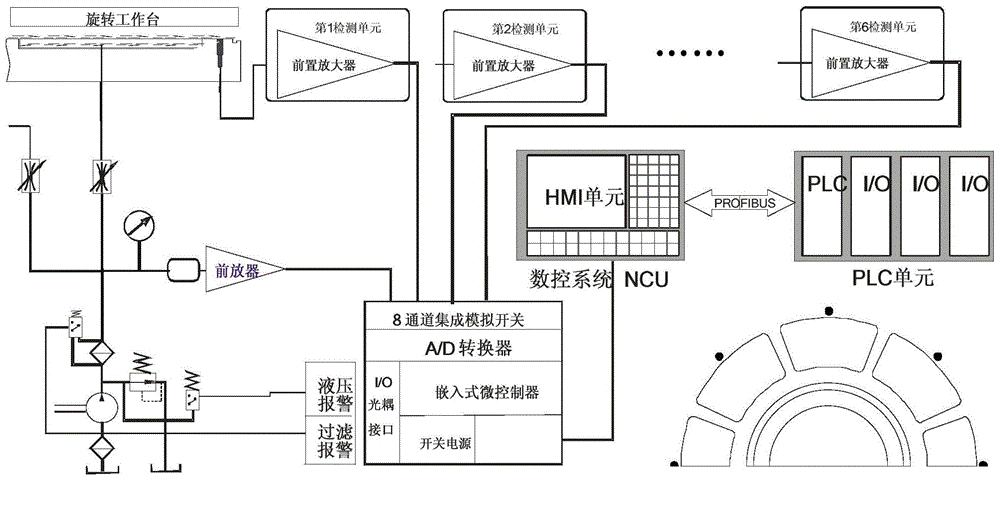

[0018] As shown in the figure, the static pressure guide rail working condition monitoring device provided by the present invention includes an eddy current sensor and a pressure sensor arranged on the static pressure oil chamber to obtain the working state signal of the static pressure oil chamber; the eddy current sensor will indirectly obtain the static pressure Press the oil film thickness value of the sliding surface of the guide rail, convert it into an analog electric power signal and transmit it to the preamplifier for amplification and conditioning processing, and then convert it into a digital signal through the A / D converter, and then transmit the dynamic dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com