car side light

A technology for edge lights and automobiles, applied to vehicle components, optical signals, signaling devices, etc., to achieve the effects of reducing danger, excellent wear resistance and elasticity, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of automobile side light, the said automobile side light is set at the front edge of the roof and the position between the front edge of the roof and the edge of the vehicle body corresponding to the bottom of the two rear view mirrors respectively, the said automobile side light includes a lamp and an FPC, and the FPC is a flexible Circuit board, a printed circuit with high reliability and excellent flexibility made of polyester film or polyimide as the base material, formed by etching on copper foil, the lamps include xenon lamps and LED lamps, wherein the xenon lamps and LED lamps are alternately arranged at intervals, and the manufacturing process of the automobile side lamps includes the following steps:

[0021] (1) Add black opaque silicone rubber and butadiene rubber (3:1) into a mixer at 280-300°C to make a glue solution, and inject it into a mold of an injection molding machine to obtain 30 xenon lampshades and LED lampshade;

[0022] Among them, the i...

Embodiment 2

[0033] Example 2: The rest is the same as the above Example 1, the difference is that in step (1), 35 xenon lampshades and LED lampshades are made respectively, and the injection molding conditions are 260°C, 55Mpa, and the injection time is In step (2), place a lampshade every 4cm. In step (3), the injection molding condition is 220°C, 90Mpa, injection molding takes 2s, and the spot welding condition is welding temperature is 200°C. After welding for 2s, the welding place is cooled for 15 minutes cure, step

Embodiment 3

[0034] Example 3: The rest is the same as that of Example 1, except that in step (1), 40 xenon lampshades and LED lampshades are made respectively, and the injection molding conditions are 265°C, 50Mpa, and the injection time is For 15s, in step (2), place a lampshade every 3cm, in step (3), the injection molding condition is 240°C, 80Mpa, injection molding for 5s, the spot welding condition is welding temperature is 190°C, after welding for 3s, the welding place is cooled 20min curing

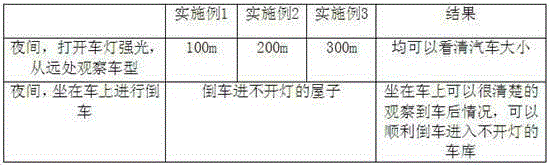

[0035] In the above three embodiments,

[0036]

[0037] The automobile side light and its preparation method have a reasonable structure, and the vehicle itself has low visibility during driving at night, and other vehicles cannot be observed when the distance is relatively long. When a novice is not skilled in turning on and changing lights, the risk factor is also very high. There are side lights on the front edge of the roof and the front edge of the roof to the edge of the car body co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com