A kind of preparation method of boron phosphate modified carbon nanotube

A technology of carbon nanotubes and boron phosphate, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of destroying the structure of carbon nanotubes, complex modification methods, weakening the physical properties of carbon nanotubes, etc. problems, to achieve the effect of good compatibility, simple method and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of boron phosphate modified carbon nanotubes, the steps are as follows:

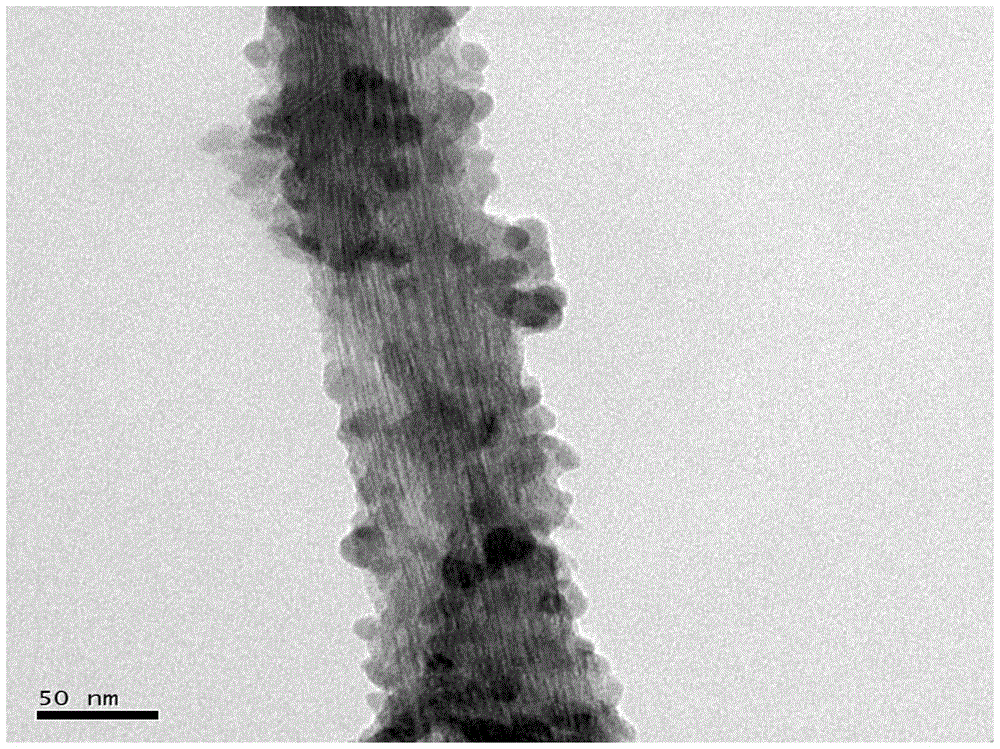

[0027] (1) preparation concentration is 100ml of Tris (trishydroxymethylaminomethane) solution of 1mmol / L, the hydrochloric acid regulation solution pH value that adds 0.1mol / L is 10, obtains alkaline solution; 500mg dopamine and 500mg carbon nanotube ( 10nm in diameter and 15-30um in length) placed in the prepared alkaline solution, ultrasonically dispersed for 1 hour, continued to stir at room temperature for 2 hours, then vacuum filtered, washed 3 times with absolute ethanol, and then deionized water Washing 3 times until the filtrate is colorless and drying to obtain polydopamine-modified carbon nanotubes (DOPA-CNTs);

[0028] (2) Add 100 mg of dried DOPA-CNTs obtained in step (1) together with 150 mg of solid phosphoric acid into 200 ml of N,N-dimethylacetamide (DMAC), ultrasonically disperse for 1 hour, then heat up under continuous magnetic stirring to 80° C., then slo...

Embodiment 2

[0031] A preparation method of boron phosphate modified carbon nanotubes, the steps are as follows:

[0032] (1) preparation concentration is the Tris (trishydroxymethylaminomethane) solution 100ml of 10mmol / L, the hydrochloric acid regulation solution pH value that adds 0.1mol / L is 9, obtains alkaline solution; 200mg dopamine and 200mg carbon nanotube ( 10nm in diameter and 15-30um in length) placed in the prepared alkaline solution, ultrasonically dispersed for 1 hour, continued to stir at room temperature for 4 hours, then vacuum filtered, washed 3 times with absolute ethanol, and then deionized water Washing 3 times until the filtrate is colorless and drying to obtain polydopamine-modified carbon nanotubes (DOPA-CNTs);

[0033] (2) Add 80 mg of dried DOPA-CNTs obtained in step (1) together with 75 mg of solid phosphoric acid into 200 ml of N,N-dimethylacetamide (DMAC), ultrasonically disperse for 1 hour, and heat up under continuous magnetic stirring to 80° C., then slowl...

Embodiment 3

[0036] A preparation method of boron phosphate modified carbon nanotubes, the steps are as follows:

[0037] (1) preparation concentration is 100ml of Tris (trishydroxymethylaminomethane) solution of 20mmol / L, the hydrochloric acid regulation solution pH value that adds 0.1mol / L is 8, obtains alkaline solution; 100mg dopamine and 100mg carbon nanotube ( 10nm in diameter and 15-30um in length) placed in the prepared alkaline solution, ultrasonically dispersed for 1 hour, continued to stir at room temperature for 8 hours, then vacuum filtered, washed 3 times with absolute ethanol, and then deionized water Washing 3 times until the filtrate is colorless and drying to obtain polydopamine-modified carbon nanotubes (DOPA-CNTs);

[0038] (2) Add 60 mg of the dried DOPA-CNTs obtained in step (1) together with 38 mg of solid phosphoric acid into 100 ml of N,N-dimethylacetamide (DMAC), ultrasonically disperse for 1 hour, and heat up under continuous magnetic stirring to 80°C, then slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com