Sulfydryl-modified graphene oxide and preparation method thereof

A technology of graphene and graphene sheets, applied in the field of nanomaterials, to achieve the effects of broadening the synthesis means and application fields, less time and energy consumption, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

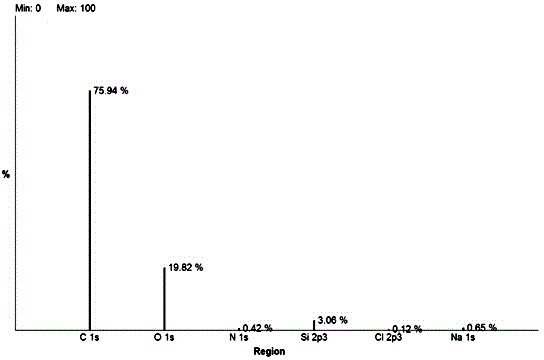

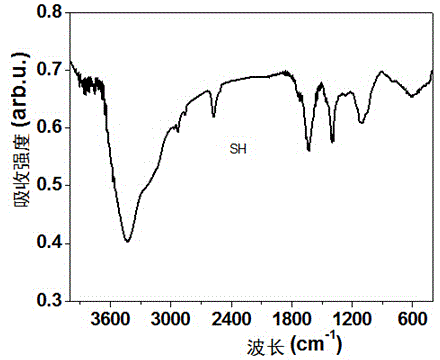

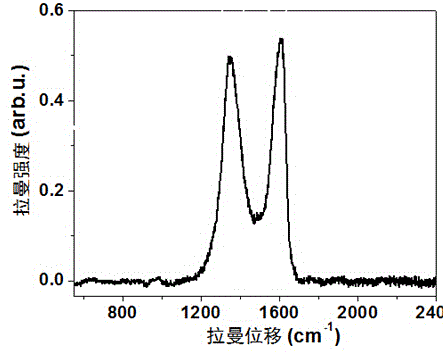

[0019] Take 2 mL of a 100 mg / mL graphene oxide solution dissolved in DMF and a powder particle size of 40 μm in a 25 mL flask, add 12 mL of deionized water and 300 μL of triethylamine to it, and add 20 mg of thiol during 20 minutes of nitrogen gas flow. Sodium acetate, stirred and reacted at room temperature for 2 days to obtain thioester-modified latent sulfur graphene oxide. The obtained product was washed with deionized water and stirred for 24 hours to obtain mercapto-modified graphene oxide. The obtained mercapto-modified graphene oxide product was characterized by XPS spectrum, infrared spectrum and Raman spectrum. The XPS spectrum of the mercapto-modified graphene oxide ( figure 2 ) and the XPS spectrum of graphene oxide ( figure 1 ) for comparison, it can be found that 1.06% of sulfur elements appeared in the mercapto-modified graphene oxide product, indicating that the introduction of mercapto groups may be successful; the infrared spectrum of the mercapto-modified...

Embodiment 2

[0021] Take 2 mL of 100 mg / mL graphene oxide solution dissolved in DMF in a 25 mL flask, add 12 mL of deionized water and 300 μL of triethylamine to it, add 60 μL of thioacetic acid during 20 minutes of blowing nitrogen gas, and incubate at 40 °C The reaction was stirred for 2 days to obtain thioester-modified latent sulfur graphene oxide. The obtained product was washed with deionized water and stirred for 24 hours to obtain mercapto-modified graphene oxide.

Embodiment 3

[0023] Take 2 mL of 100 mg / mL graphene oxide solution dissolved in DMSO in a 25 mL flask, add 12 mL of deionized water and 300 μL of triethylamine to it, add 60 μL of thioacetic acid during 20 minutes of blowing nitrogen gas, and incubate at 40 °C The reaction was stirred for 2 days to obtain thioester-modified latent sulfur graphene oxide. Add 100 mL of 5% dilute hydrochloric acid to the obtained product, then wash with deionized water, and stir for 24 hours to obtain mercapto-modified graphene oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com