A treatment device for refractory wastewater and a wastewater treatment method thereof

A treatment device and wastewater treatment technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problems of complex treatment process and high energy consumption, and achieve accelerated chemical reactions, Effects of reduced energy consumption and shortened response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

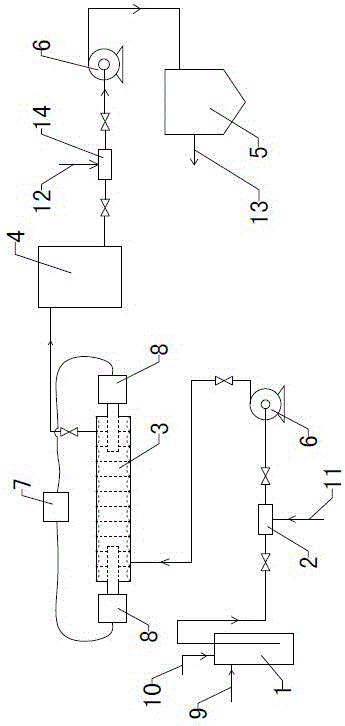

[0029] Papermaking fluorescent whitening agent wastewater COD is 1161mg / L after biochemical treatment, adopts the method of the present invention to treat, wastewater treatment capacity is 100L / h, adjust wastewater pH with sulfuric acid to be 3.1, then add oxidant and Fe3 + catalyst, oxidant H2O2 ( Concentration 30%) dosing concentration is 1.4mL / L, Fe3+ catalyst dosing concentration is 0.85g / L, oxidant and Fe3+ catalyst molar ratio is 4:1. The waste water is pumped into the single-frequency opposite-shooting tube-type ultrasonic reactor with a corrugated inner wall, the ultrasonic frequency is 20KHz, the ultrasonic action intensity is 0.13 W / cm2, and the ultrasonic action time is 30S, and then enters the catalytic reaction pool, and the reaction time is 30min , the catalyzed reaction effluent is adjusted to pH 7.1 by adding alkali, and then enters the sedimentation tank for solid-liquid separation. The COD of the supernatant is 220mg / L, and the COD removal rate is 81.1%, reach...

Embodiment 2

[0031] Papermaking fluorescent whitening agent wastewater is biochemically treated with a COD of 1161mg / L, treated by the method of the present invention, the wastewater treatment capacity is 110L / h, the pH of the wastewater is adjusted to 3.5 with sulfuric acid, and then the oxidant and Fe are added 2+ Catalyst, Oxidant H 2 o 2 (Concentration 30%) Dosing concentration is 3.1mL / L, Fe 2+ Catalyst dosage concentration is 1.5g / L, oxidant and Fe 2+ The catalyst molar ratio was 5:1. The waste water is pumped into the single-frequency opposite-shooting tube-type ultrasonic reactor with a corrugated inner wall, the ultrasonic frequency is 25KHz, and the ultrasonic action intensity is 0.18 W / cm 2 , the ultrasonic action time is 25S, and then enters the catalytic reaction tank, the reaction time is 35min, the catalytic reaction effluent is adjusted to pH 7.5 by adding alkali, and then enters the sedimentation tank for solid-liquid separation. The supernatant COD is 160mg / L, and the CO...

Embodiment 3

[0033] Papermaking fluorescent whitening agent wastewater COD is 738mg / L after biochemical treatment, adopts the method of the present invention to handle, and wastewater treatment capacity is 100L / h, adjusts wastewater pH with sulfuric acid to be 2.5, then adds oxidant and catalyst, Mn 2+ Oxidant H 2 o 2 (Concentration 30%) Dosing concentration is 7mL / L, Mn 2+ Catalyst dosage concentration is 1.7g / L, oxidant and Mn 2+ The catalyst molar ratio was 10:1. The waste water is pumped into the single-frequency opposite-shooting tube-type ultrasonic reactor with a corrugated inner wall, the ultrasonic frequency is 15KHz, and the ultrasonic action intensity is 0.1 W / cm 2 , the ultrasonic action time is 10S, and then enters the catalytic reaction tank, the reaction time is 60min, the catalytic reaction effluent is adjusted to pH 7.0 by adding alkali, and then enters the sedimentation tank for solid-liquid separation. The supernatant COD is 146mg / L, and the COD removal rate was 80.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com