A kind of high-frequency low-loss glass-ceramic containing lanthanum oxide and its preparation method

A glass-ceramic and lanthanum oxide-containing technology, which is applied in the field of high-frequency and low-loss microwave dielectric materials and their manufacturing, can solve the problems of lowering the product qualification rate, unable to monitor glass bubbles in real time, increasing production costs, etc. efficiency, ease of control, improved transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] 1. Preparation of Pristine Glass

[0034] 1) Batching and mixing: Weigh quartz sand, magnesium oxide, aluminum oxide, titanium oxide, cerium oxide and lanthanum oxide and other raw materials according to the distribution ratio of the glass-ceramics and mix them into glass batches. The purity of the above raw materials does not need to be strictly required, and it is only necessary to control the content of monovalent alkali metal <0.5%. For example, abundant and cheap chemical raw materials can be used to reduce production costs.

[0035] 2) Melting: Put the glass batch material into the crucible, melt it at 1450-1530℃ and keep it warm for 2-4 hours, then pour it into the mold and cast it into shape.

[0036] 3) Annealing: heat preservation at 620-660°C for 3-5 hours in the annealing furnace, then cool down to room temperature with the furnace, so as to obtain the original glass.

[0037] In the present invention, use La 2 o 3 replace CeO 2 , can significantly impr...

Embodiment 1

[0048] Glass composition (wt%) is:

[0049] MgO Al 2 o 3 SiO 2 TiO 2 CeO 2 La 2 o 3

[0050] 7.7 23.2 32.0 18.2 6.5 12.4

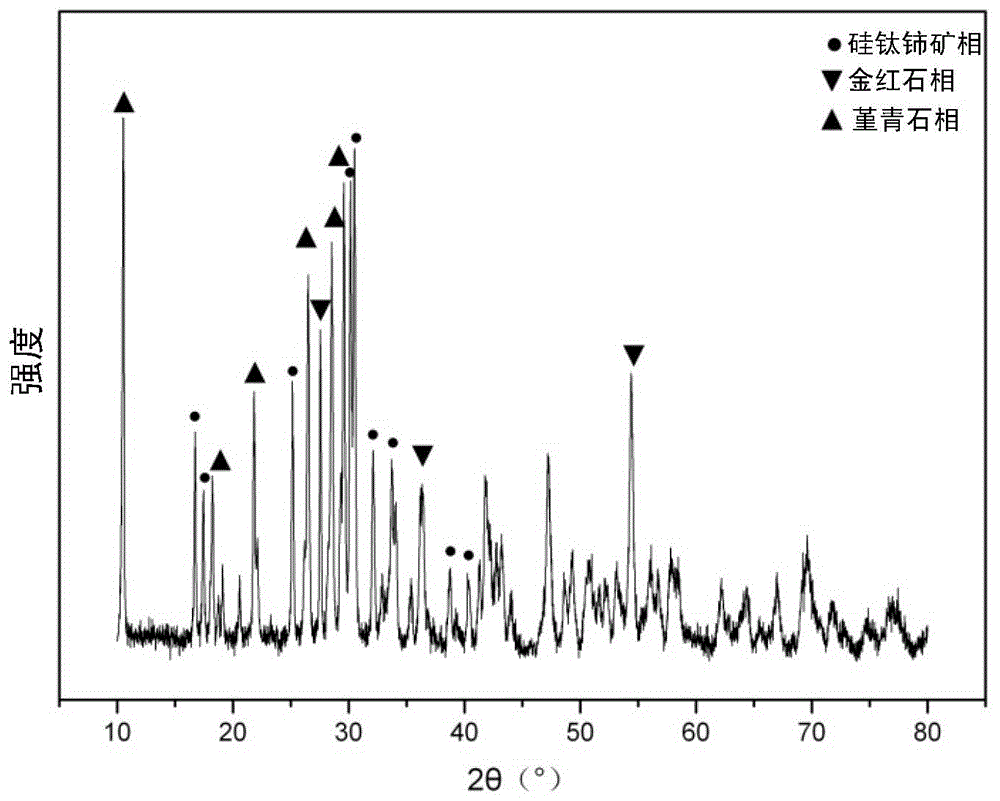

[0051] Quartz sand, magnesium oxide, aluminum oxide, titanium oxide, cerium oxide and lanthanum oxide are used as raw materials, weighed and mixed according to the above components, melted at 1520 ° C for 3 hours, poured into cast iron molds, and placed in an annealing furnace for 640 °C ℃ for 4 hours and then cooled to room temperature with the furnace to obtain brown-red transparent glass. Then the temperature was raised from room temperature to 1250 °C at a rate of 5 °C / min, kept for 2 hours, and then cooled to room temperature with the furnace to obtain a high-frequency high-quality factor glass-ceramic dielectric material. The dielectric constant is 10.99, the quality factor is 19464GHz, and other properties are shown in Table 1. figure 1 The XRD spectrum of the glass-ceramics prepared in this example, the abscissa is 2 times the diffrac...

Embodiment 2

[0053] Glass composition (wt%) is:

[0054] MgO Al 2 o 3 SiO 2 TiO 2 La 2 o 3

[0055] 8.2 24.9 34.2 19.5 13.2

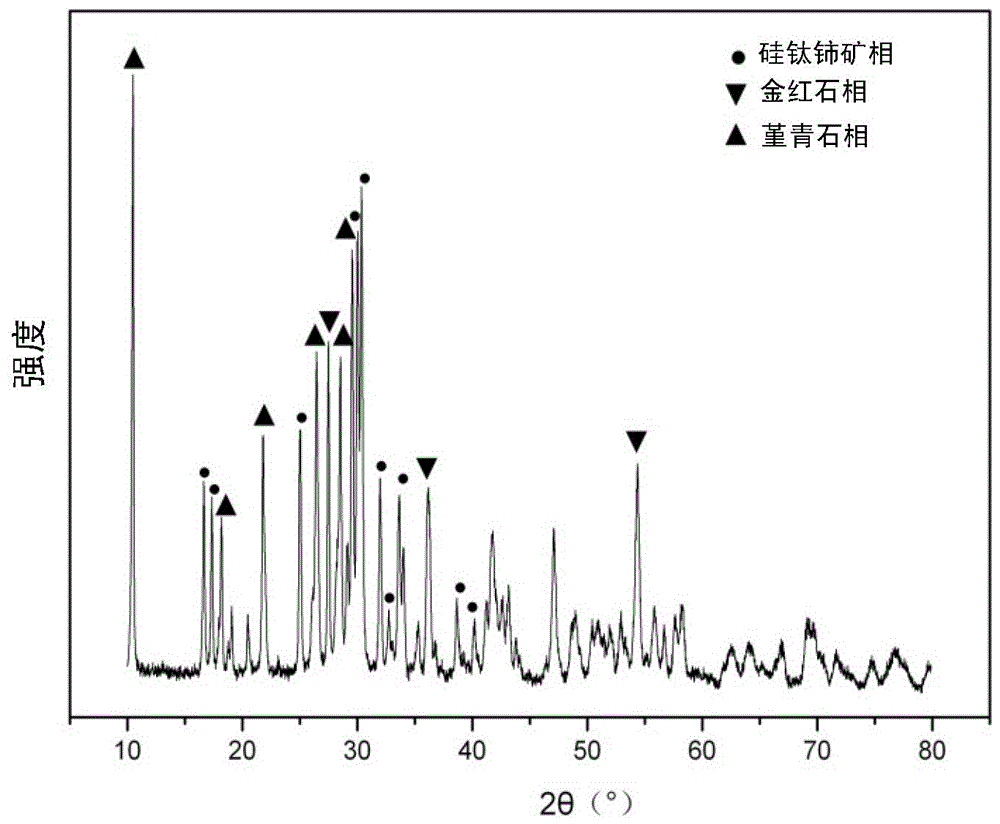

[0056] Use quartz sand, magnesium oxide, aluminum oxide, titanium oxide and lanthanum oxide as raw materials, weigh and mix according to the above components, melt at 1520°C for 3 hours, pour it into a cast iron mold, and place it in an annealing furnace for 4 hours at 640°C After cooling to room temperature with the furnace, brownish-yellow transparent glass was obtained. Then the temperature was raised from room temperature to 1150 °C at a rate of 5 °C / min, kept for 10 hours, and then cooled to room temperature with the furnace to obtain a high-frequency high-quality factor glass-ceramic dielectric material. The dielectric constant is 10.59, the quality factor is 22398GHz, and other properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com