A method for preparing hollow rod-shaped hemihydrate gypsum from desulfurized gypsum

A technology for desulfurized gypsum and hemihydrate gypsum, applied in the field of gypsum, can solve the problems of limited application scope and potential application value, narrow particle distribution band, high water content, and achieve broad scientific research and application prospects, narrow diameter range distribution, and whiteness. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

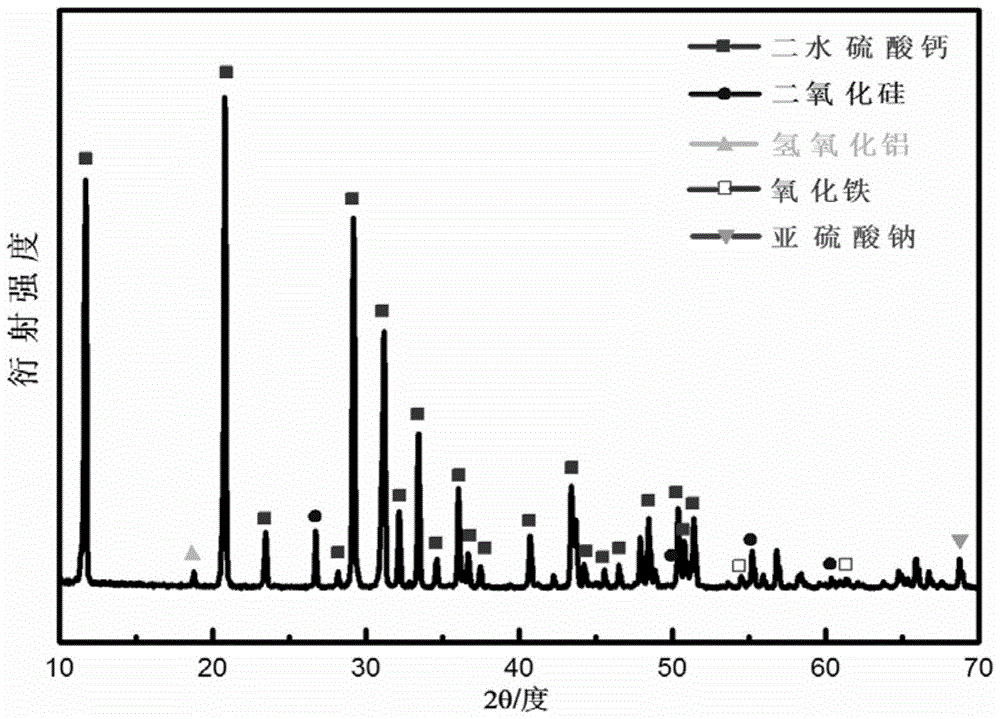

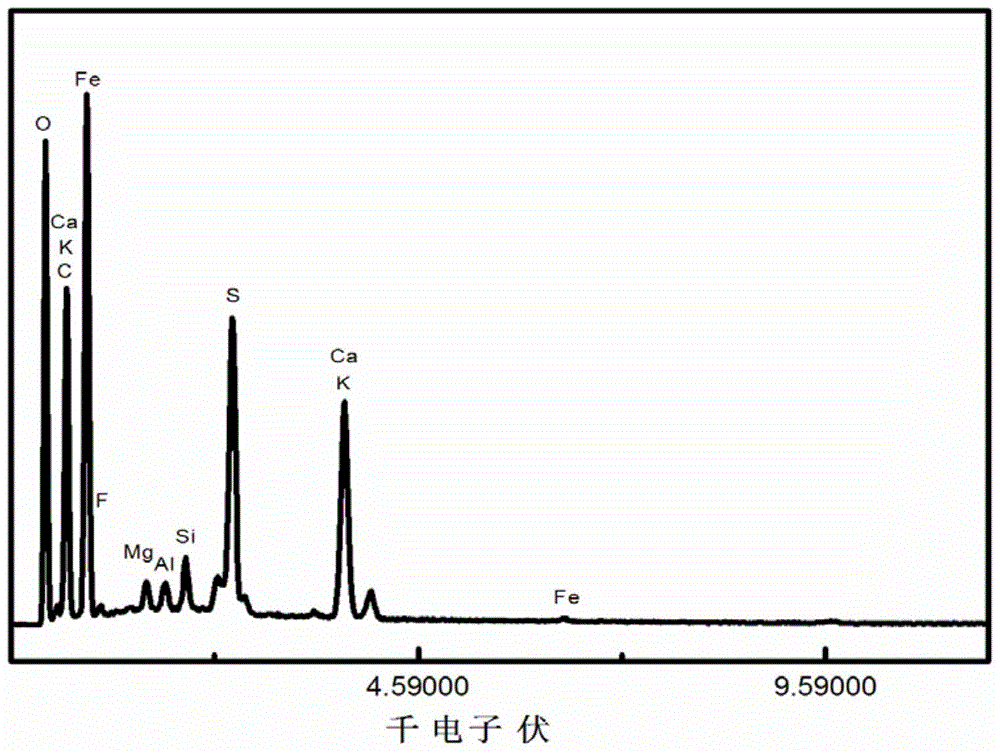

[0022] Take 3g of desulfurized gypsum, sieve through a 230 mesh sieve to obtain desulfurized gypsum fine powder, then take 6ml of alcohol with a mass fraction of 99%, and 5ml of hydrochloric acid with a mass fraction of 36%, add them in sequence, mix and stir, and prepare the original slurry , put it into a water bath, keep it warm at normal pressure and 80°C for 30 minutes, put the slurry into a centrifuge and centrifuge it at 10,000 r / s for 10 minutes, take out the centrifuged slurry, pour off its supernatant, and get The white solid was put into a drying oven, and after drying at 70° C., the final hollow rod-shaped hemihydrate gypsum was obtained.

Embodiment 2

[0024] Take 1g of desulfurized gypsum, sieve through a 230 mesh sieve to obtain desulfurized gypsum fine powder, then take 5ml of alcohol with a mass fraction of 99%, and 2ml of hydrochloric acid with a mass fraction of 36%, add them in sequence, mix and stir, and prepare the original slurry , put it in a water bath, keep it warm at normal pressure and 90°C for 20 minutes, put the slurry into a centrifuge and centrifuge at 10,000 r / s for 5 minutes, take out the centrifuged slurry, pour off its supernatant, and get The white solid was put into a drying oven, and after drying at 60° C., the final hollow rod-shaped hemihydrate gypsum was obtained.

Embodiment 3

[0026] Take 0.5g of desulfurized gypsum, sieve through a 230 mesh sieve to obtain desulfurized gypsum fine powder, then take 5ml of alcohol with a mass fraction of 99%, and 3ml of hydrochloric acid with a mass fraction of 36%, add them in sequence, mix and stir, and prepare the original slurry Put the material into a water bath, keep it warm at normal pressure and 85°C for 25 minutes, put the slurry into a centrifuge and centrifuge at 10,000 r / s for 5 minutes, take out the centrifuged slurry, pour off the supernatant, and The obtained white solid was put into a drying oven, and after drying at 50° C., the final hollow rod-shaped hemihydrate gypsum was obtained.

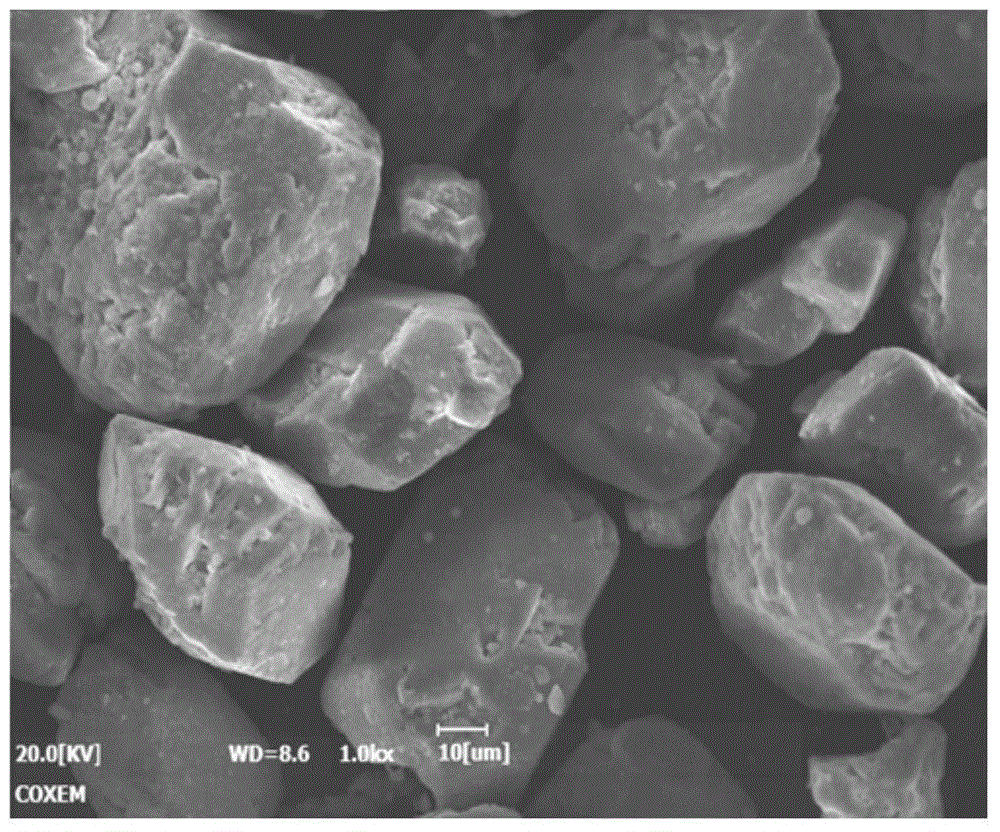

[0027] The obtained hollow rod-shaped hemihydrate gypsum of above-mentioned embodiment 1-3 is basically similar, all can refer to attached Figure 4-6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com