Platinum conveying device and preparation method for electronic glass manufacturing and filling material thereof

A conveying device and glass manufacturing technology, applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc., can solve the problems of low sintering temperature, inability to sinter, affecting the uniformity of the temperature distribution of the platinum conveying device, etc., to achieve uniform sintering, Conducive to uniform sintering and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

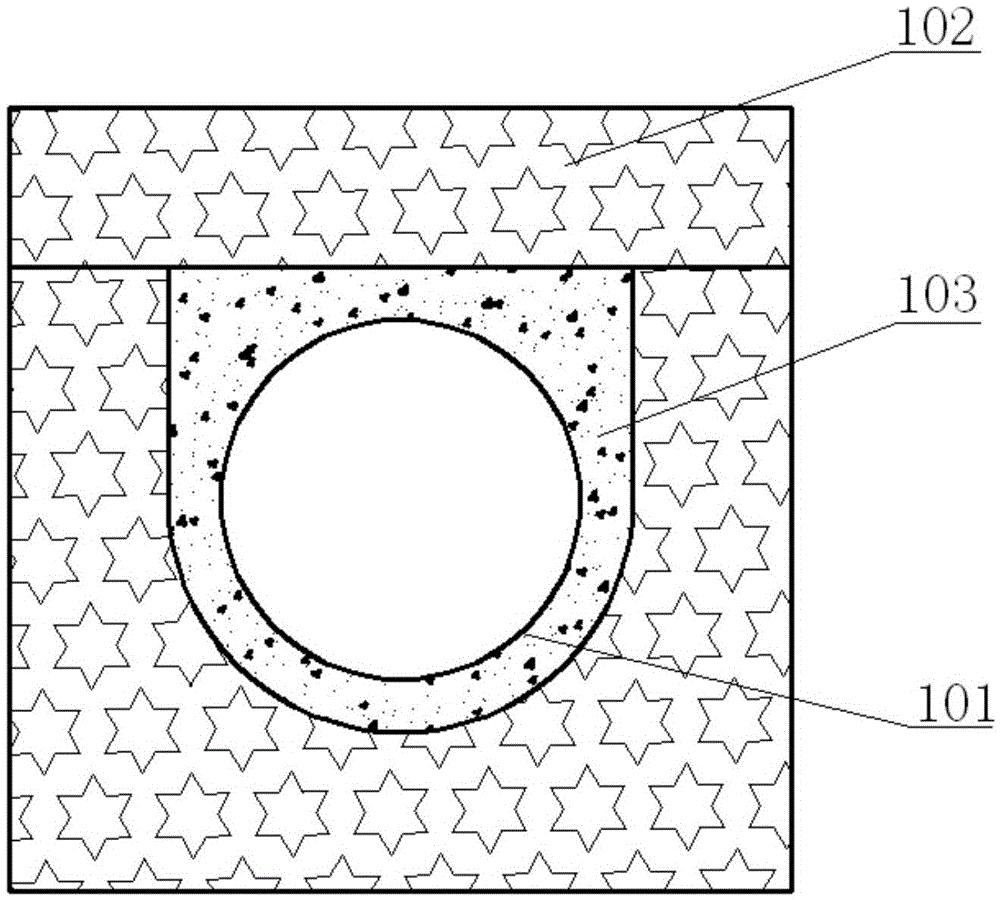

[0033] see figure 1 , the present invention comprises platinum conveying device 101, and the periphery of platinum conveying device 101 is provided with thermal insulation material 102, and thermal insulation material 102 carries out support and heat preservation; Leave the gap of 5~50mm between platinum conveying device 101 and thermal insulation material 102, add in this gap ZrO 2 The filling material 103 is based, wherein the filling material 103 is first dried at 100-140° C. for 3-5 hours to remove moisture; then added to the gap and sintered at 1100-1600° C. for 2-4 hours.

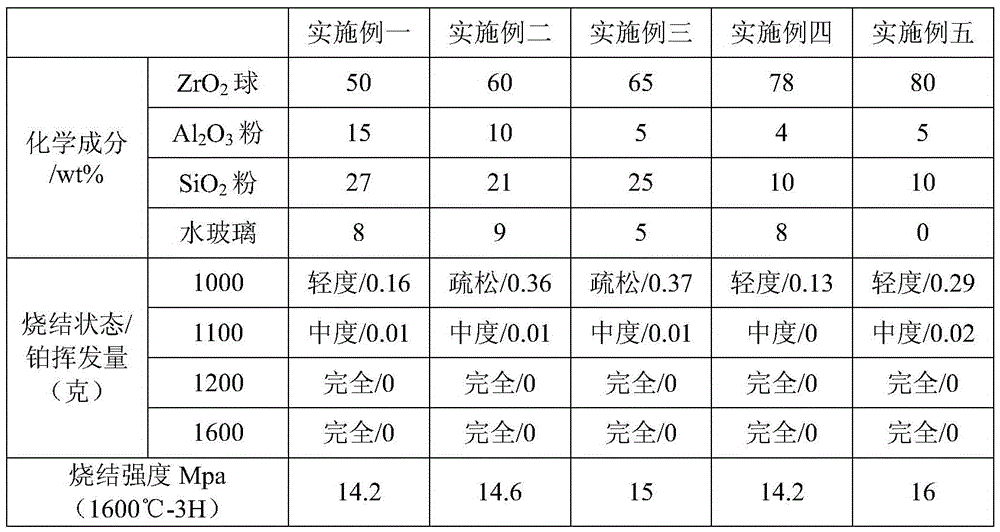

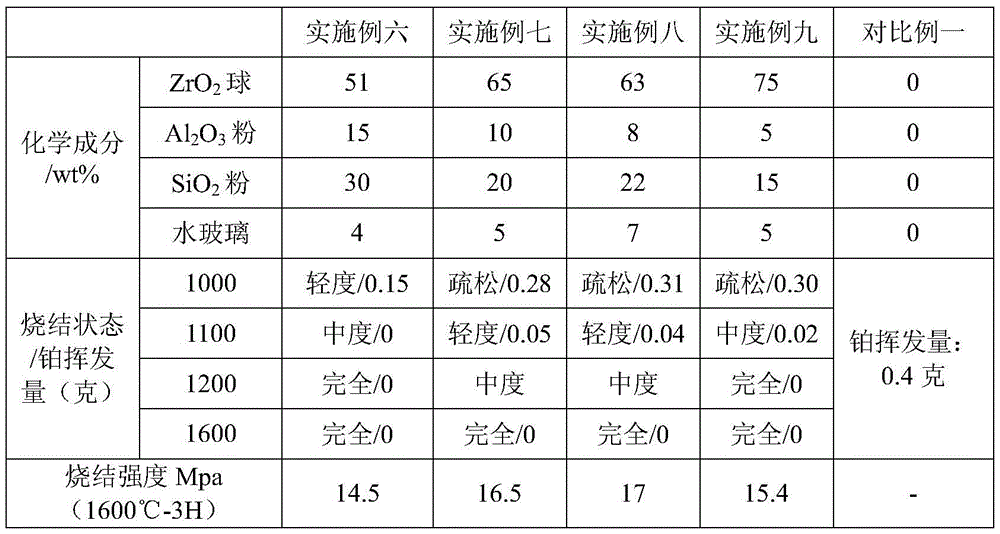

[0034] In terms of mass percentage, the filling material includes ZrO 2 : 50~80%, Al 2 o 3 : 3~15%, SiO 2 : 10-30%, water glass: <10%, of which the Baume degree of water glass is 9.9-45°Bé, which is liquid and easy to flow, so that the filling material can penetrate into the gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com