Method for manufacturing fried food packaging film

A technology for fried food and packaging film, applied in packaging, wrapping paper, biological packaging, etc., can solve the problems of packaging pollution, strength reduction, oil exposure, etc., to achieve good oil resistance and avoid oil pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

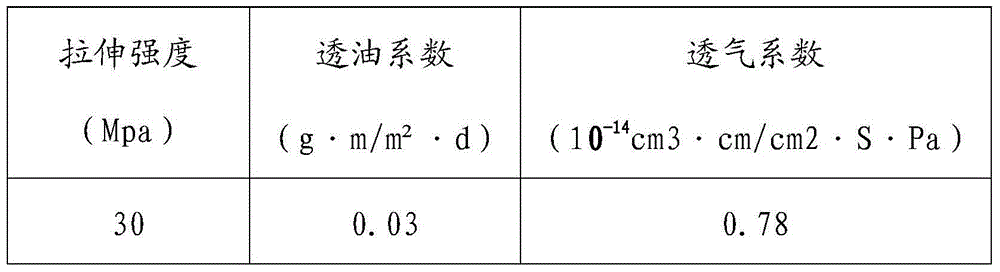

Examples

Embodiment 1

[0017] A method for making a fried food packaging film, comprising the steps of:

[0018] 1) Get a certain amount of water-soluble chitosan, dissolve it with distilled water, and configure a chitosan solution with a concentration of 2%;

[0019] 2) Mix raw potato starch and cross-linked esterified starch in a weight ratio of 3:1, then dissolve them in distilled water, configure a starch solution with a concentration of 20%, and gelatinize at 75°C for half an hour;

[0020] 3) After the starch solution is completely gelatinized, cool it down to 45°C quickly, add isoamylase at 50u isoamylase / g starch, and stir at constant temperature for 3 hours;

[0021] 4) Mix the polychitosan solution and the starch solution in a weight ratio of 1:10, and stir for 30 minutes at a speed of 550 r / min;

[0022] 5) Warm up the mixed solution after stirring to 60° C., add polyethylene glycol accounting for 3% by weight of the mixed solution, and continue stirring for 20 minutes;

[0023] 6) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com