Waste shoe sole rubber powder activation method and application thereof

An activation method and waste technology, applied in recycling technology, plastic recycling, etc., can solve the problems of difficult to cut sulfur, unfavorable environmental protection, increase waste water discharge, etc., to reduce production costs, ensure quality, and stabilize the temperature control system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

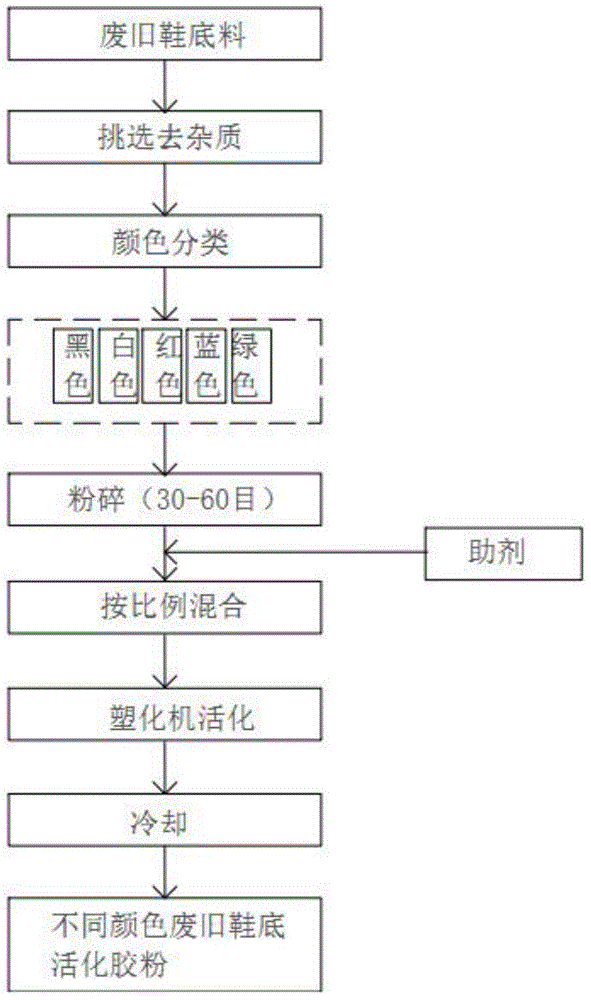

Method used

Image

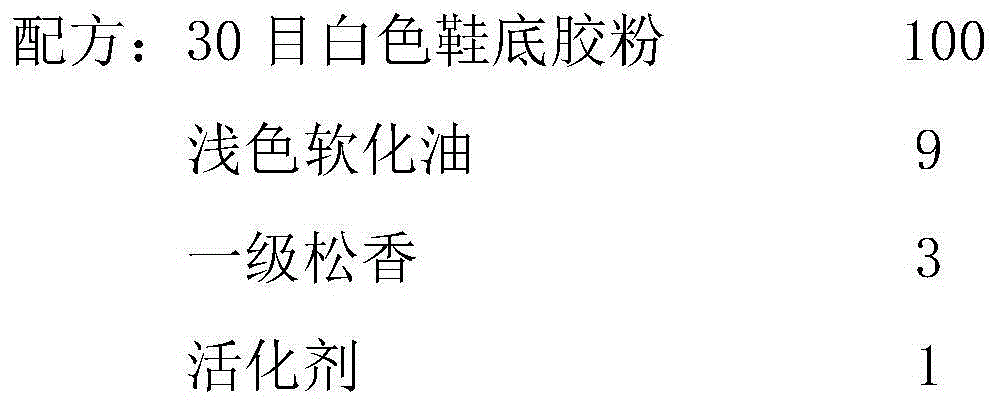

Examples

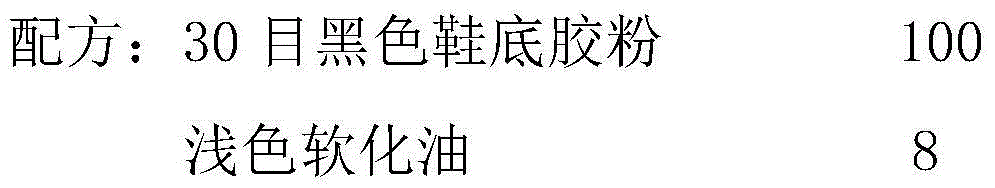

Embodiment 3

[0035]

[0036] Process: Activation temperature is 280°C, host speed is 22Hz.

[0037] After the obtained activated rubber powder was masticated on the open mill for 1 minute and 30 seconds, it was tested with the reclaimed rubber produced from the same raw material according to the requirements of the GB / T 13460-2008 standard. The comparative data obtained are shown in Table 1.

[0038] Table 1 The data comparison between activated rubber powder for soles of the present invention and reclaimed rubber for soles

[0039]

[0040] It can be seen from Table 1 that the acetone extractives of shoe sole activated rubber powder decreased significantly due to the decrease of softener dose, and other data basically remained unchanged.

[0041] Get the activated rubber powder that the present invention makes and carry out hazardous substance detection (SGS test report), the data of detection is shown in the following table:

[0042] project

[0043] Cadmium (Cd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com