A low energy consumption, photodegradable polyethylene composition and its preparation method

A technology of polyethylene and photodegradation, which is applied in the field of polyethylene film processing, can solve the problems of rapid and effective treatment of unfavorable plastic waste, long degradation time, and increased product cost, and achieve high ability to absorb and shield ultraviolet rays, photocatalysis The effect of high activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

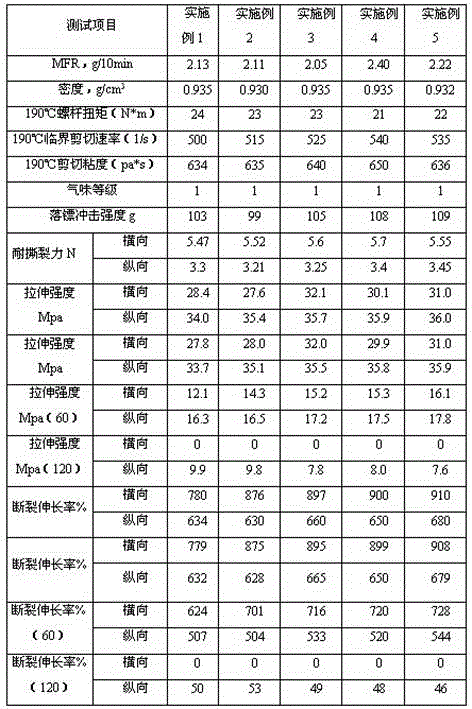

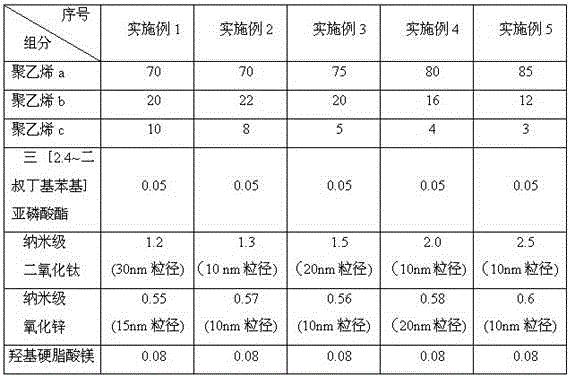

Embodiment 1

[0039] Polyethylene a is a powder, and ethylene and hexene~1 are copolymerized. Its density is 0.923g / cm 3 , the melt mass flow rate (MFR) is 2.55g / 10min, the melting temperature is 122.6°C, the degree of branching is 1.9, the weight average molecular weight is 90,000, and the molecular weight distribution width index is 4.0.

[0040] Polyethylene b as pellets, metallocene linear low density polyethylene, density 0.918g / cm 3 , Melt mass flow rate (190°C, 2.16Kg) 1.0g / 10min branch point 111 / 10000C, terminal methyl group 127 / 10000C, weight average molecular weight 100,000, molecular weight distribution breadth index 3.8.

[0041] Polyethylene c is pellets, linear low density polyethylene, its density is 0.9251g / cm 3 , the melt mass flow rate (MFR) is 19.18g / 10min, the melting temperature is 122.3°C, and the relative branching degree is 1.31.

Embodiment 2

[0043] Polyethylene a is a powder, and ethylene and butene ~1 are copolymerized. Its density is 0.920g / cm 3 The melt mass flow rate (MFR) is 1.93g / 10min, the melting temperature is 121.1°C, the degree of branching is 2.2, the weight average molecular weight is 120,000, and the molecular weight distribution breadth index is 4.2.

[0044] Polyethylene b is powder, metallocene linear low density polyethylene, density is 0.9158g / cm 3 , Melt mass flow rate (190℃, 2.16Kg) 2.0g / 10min, branch point is 112 / 10000C, comonomer hexene mole percentage is 1.9%, terminal methyl group is 128 / 10000C, molecular weight distribution width Index 2~4, weight average molecular weight 100,000~150,000.

[0045] Polyethylene c is a pellet, linear low-density polyethylene, and its density is 0.9263g / cm 3 , the melt mass flow rate (MFR) is 21.6g / 10min, the melting temperature is 119.3°C, and the relative branching degree is 1.28.

Embodiment 3

[0047] Polyethylene a is a powder, and ethylene and butene ~1 are copolymerized. Its density is 0.9228g / cm 3 , the melt mass flow rate (MFR) is 2.01g / 10min, the melting temperature is 122.4°C, the relative branching degree is 2.0, the weight average molecular weight is 100,000, and the molecular weight distribution width index is 4.4.

[0048] Polyethylene b is powder, prepared by metallocene catalyst, comonomer hexene, hexene molar percentage is 2.0%, branch point is 112 / 10000C, terminal methyl group is 125 / 10000C, molecular weight distribution breadth index is 2.5, weight The average molecular weight is 115,400, the melt mass flow rate is 1.68g / 10min, and the density is 0.9196g / cm 3。 .

[0049] Polyethylene c is pellets, linear low density polyethylene, its density is 0.9280g / cm 3 , the melt mass flow rate (MFR) is 23.6g / 10min, the melting temperature is 121.5℃, and the relative branching degree is 1.27.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com