Polypropylene composition and preparation method thereof

A polypropylene composition and polypropylene resin technology, applied in the field of polyolefin resin materials, can solve the problems of high processing temperature, high haze value, poor transparency, etc., and achieve a simple preparation process, excellent comprehensive performance and high transparency. Effect

Inactive Publication Date: 2015-04-29

CHINA PETROLEUM & CHEM CORP

View PDF4 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (1) The transparency of the product is not high, which affects the appearance quality of the product;

[0005] (2) The processing fluidity is not good, the mold filling is difficult, and the processing temperature is too high;

[0006] (3) There is warping and deformation in the product;

[0007] (4) The appearance of the product is yellowish, etc.

[0008] Chinese patent CN1443801A "A transparent polypropylene composition" introduces a transparent polypropylene composition obtained by adding a transparent agent and anthraquinone disperse dye, but the haze value of the material is higher than 28%, that is, the transparency is too poor, Difficult to meet the use requirements of high transparency

[0009] Chinese patent CN102399395A "Preparation method of random copolymerized transparent polypropylene resin with high flow and high ethylene content", introduces the process of obtaining the melt flow of the final product by adding antioxidant, neutralizing agent, nucleating agent and rheological masterbatch Transparent polypropylene products with a speed of 16-18g / 10min, an ethylene content of 3.6-4.0%, and a haze of less than 10%. ) The products obtained are prone to problems such as unstable fluidity, yellow appearance, and high content of volatile organic compounds (VOC) in the product.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-5

[0038] 100 parts of random copolymerized polypropylene powder, produced by hydrogen adjustment process, 0.3 part of antioxidant, 0.08 part of acid absorbing agent, 0.06 part of antistatic agent, nucleating agent A and nucleating agent B in Examples 1-5 The different proportions are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

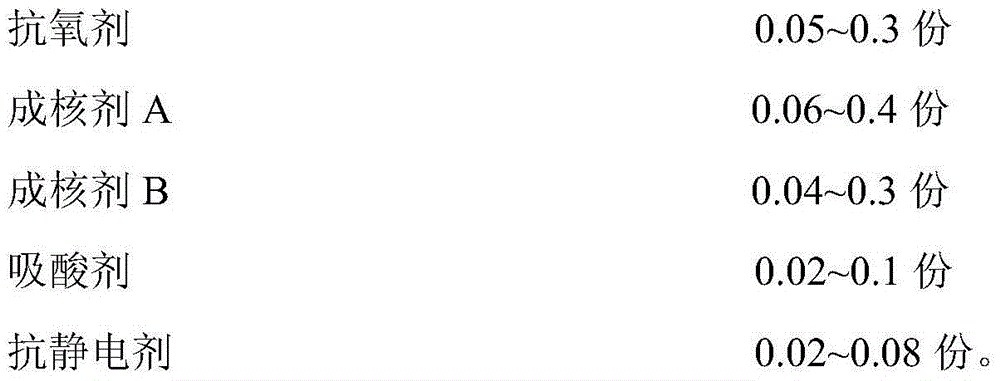

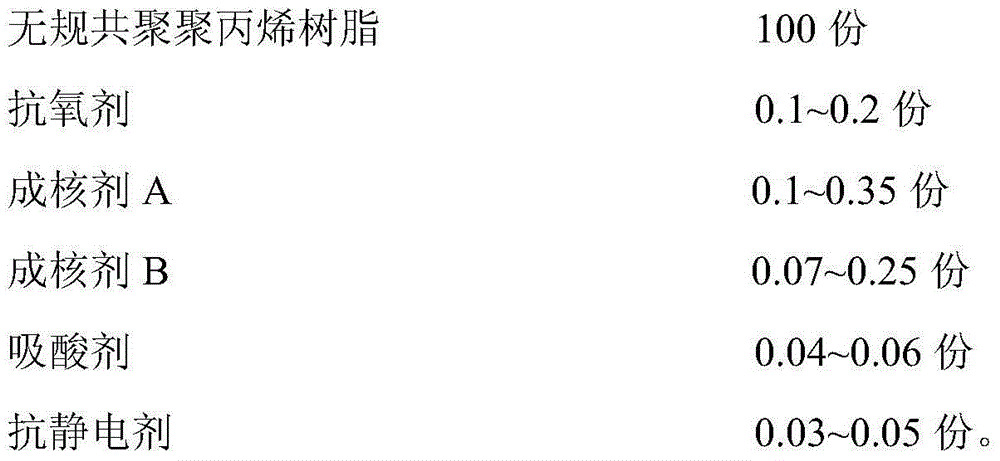

The invention belongs to the field of polyolefin resin materials, and particularly relates to a polypropylene composition and a preparation method thereof. The polypropylene composition comprises the following raw materials in part by weight: 100 parts of a polypropylene resin random copolymer, 0.05-0.3 part of an anti-oxidant, 0.06-0.4 part of a nucleating agent A, 0.04-0.3 part of a nucleating agent B, 0.02-0.1 part of an acid acceptor and 0.02-0.08 part of an antistatic agent. According to the preparation method, a high-fluidity polypropylene random copolymer, which is obtained according to the hydrogen regulation method, is used as the basis resin; additives, such as the anti-oxidant, the acid acceptor, the antistatic agent, the nucleating agent A and the nucleating agent B, are added into the basis resin; after the basis resin and the additives are uniformly mixed by a high-speed stirring machine, the high-fluidity high-transparency polypropylene composition is obtained through double-screw extrusion pelletizing. The polypropylene composition is excellent in comprehensive performance, high in transparency and fluidity, resistant to warpage, and superior to a product of the degradation method in the aspects of appearance, color, lustre and smell. Therefore, the polypropylene composition can be applied to a large-scale transparent product and a complicated thin-wall product, and the warpage phenomenon during the production can be effectively avoided.

Description

technical field [0001] The invention belongs to the field of polyolefin resin materials, and in particular relates to a polypropylene composition and a preparation method thereof. Background technique [0002] Transparent polypropylene is a hot spot in the development of new polypropylene products in recent years. In addition to the performance advantages of ordinary PP, transparent PP also has good transparency, high gloss and high heat distortion temperature. With the improvement of society's awareness of food safety and environmental protection, people's recognition of transparent polypropylene is getting higher and higher. Transparent polypropylene with safety, hygiene and excellent performance is gradually replacing traditional transparent materials such as polyethylene terephthalate. Glycol ester (PET), polystyrene (PS) polycarbonate (PC) and polyvinyl chloride (PVC) and other products. [0003] Ordinary transparent polypropylene can meet the application requirements ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/14C08K5/00B29B9/06B29C47/92B29C48/92

CPCC08K5/1545B29B9/06B29C48/92B29C2948/9258B29C2948/92704C08K5/00C08K5/098C08K5/103C08K2201/017C08L2201/10C08L2205/24C08L23/14

Inventor 李延亮唐岩李丽苑东兴陈智能黄峰陈华赉王晓蕾

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com