An oil shale dry distillation recovery system and recovery method

A recovery system and oil shale technology, applied in the field of oil shale dry distillation, can solve the problems of environmental pollution, large water consumption, large amount of sewage, etc., and achieve good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

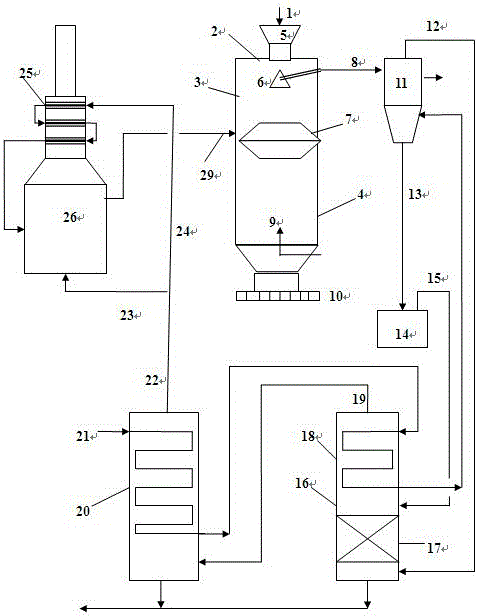

[0033]As shown in the figure, the present invention provides an oil shale dry distillation recovery system, which includes a dry distillation furnace 2, a cyclone separator 11, a sedimentation separation tank 14, an oil washing tower 16, a deep cooling tower 20 and a heating furnace 26; The retort furnace 2 includes a retort section 3 and a generator section 4 from top to bottom, an abutment 7 is arranged between the retort section 3 and the generator section 4, and a thermal cycle retort gas inlet 29 is arranged outside the wall below the retort section; The main air distribution head 9 and the ash pan 10, the cooling system is arranged outside the cyclone separator 11, and the oil washing tower 16 includes an intercooling section 18 and an oil washing section 17 from top to bottom; The separator inlet is connected, the gas phase outlet on the upper part of the cyclone separator 11 is connected to the gas inlet below the oil washing section 17 of the oil washing tower through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com