Treatment process and device for indium alkali boiled residue

A treatment process and a technology for soda cooking slag, which is applied in the field of soda cooking slag treatment technology and its devices, can solve the problems of exothermic damage to tools and equipment, large acid consumption, etc., and achieve the effect of reducing acid consumption and overcoming severe heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

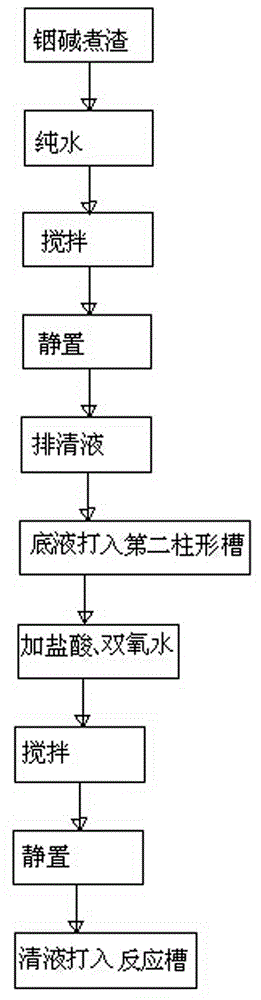

Method used

Image

Examples

Embodiment 1

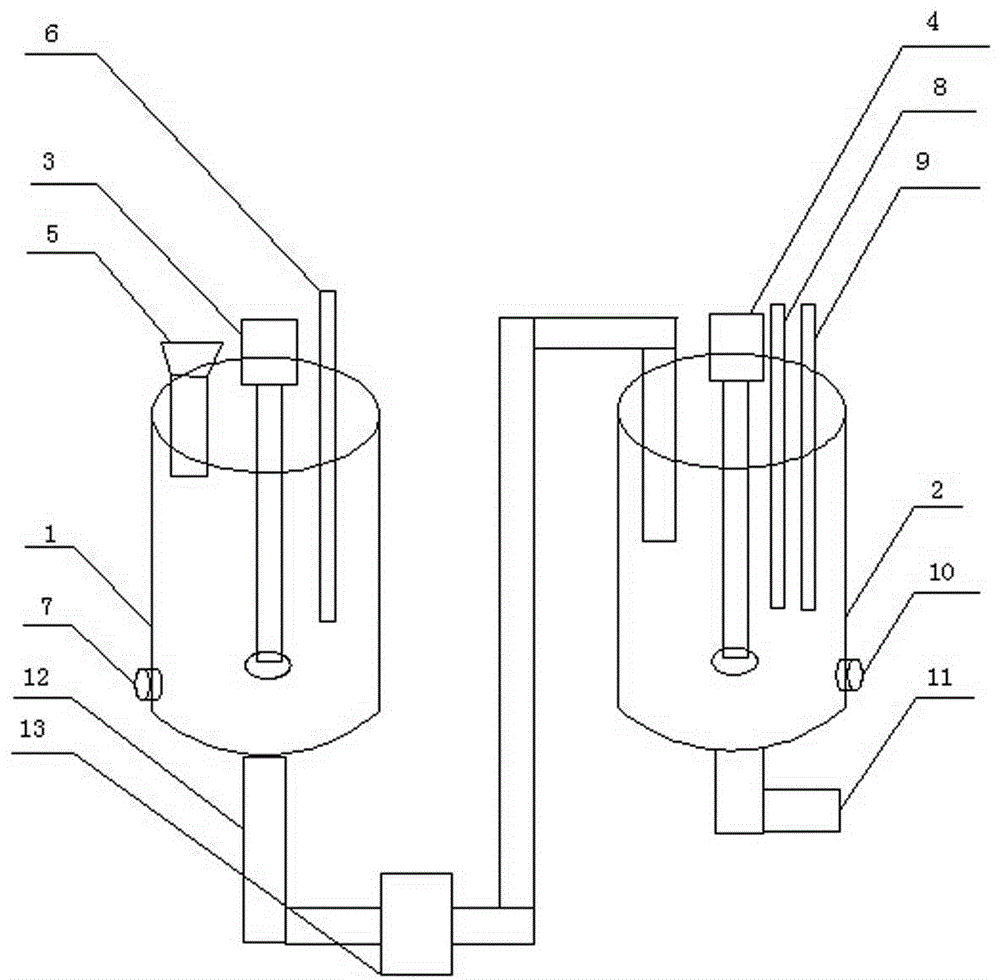

[0020] Example 1: Step 1), add 50KG indium alkali boiled slag into the reaction tank, then add 50L pure water to dissolve indium alkali boiled slag, stir for 2~3h, the stirring rate is 40r / min, and then stand for 1h to obtain the upper layer hydrogen Sodium oxide clear liquid and bottom turbid liquid Ⅰ;

[0021] Step 2), release the supernatant sodium hydroxide clear liquid in step 1), store, the concentration of sodium hydroxide solution is 25mol / L;

[0022] Step 3), put the bottom turbidity I in step 1) into another reaction tank, add 20L of hydrochloric acid at the same time, the concentration of hydrochloric acid is 3mol / L, then add 100ml of hydrogen peroxide with a mass concentration of 30%, and stir for 2~3h After that, let it stand for 1 hour, then discharge the supernatant and add it to the reaction tank of the indium production system. The acidity of the obtained supernatant is 80g / L, and the bottom turbid II is discharged for storage.

[0023] The bottom turbid...

Embodiment 2

[0026] Example 2: Step 1), add 80KG indium alkali boiled slag into the reaction tank, then add 60L pure water to dissolve indium alkali boiled slag, stir for 2~3h, the stirring rate is 40r / min, and then stand for 1h to obtain the upper layer hydrogen Sodium oxide clear liquid and bottom turbid liquid Ⅰ;

[0027] Step 2), release the supernatant sodium hydroxide clear liquid in step 1), store, the concentration of sodium hydroxide solution is 30mol / L;

[0028] Step 3), put the bottom turbidity I in step 1) into another reaction tank, add 20L of hydrochloric acid at the same time, the concentration of hydrochloric acid is 3mol / L, then add 100ml of hydrogen peroxide with a mass concentration of 30%, and stir for 2~3h After that, let it stand for 1 hour, then drain the supernatant and add it to the reaction tank of the indium production system. The acidity of the obtained supernatant is 20g / L, and the bottom turbid II is discharged for storage.

[0029] The bottom turbid II...

Embodiment 3

[0032] Example 3: Step 1), add 30KG indium alkali boiled slag into the reaction tank, then add 40L pure water to dissolve indium alkali boiled slag, stir for 2~3h, the stirring rate is 40r / min, and then stand for 1h to obtain the upper layer hydrogen Sodium oxide clear liquid and bottom turbid liquid Ⅰ;

[0033] Step 2), discharge the supernatant sodium hydroxide clear liquid in step 1), store, the concentration of sodium hydroxide solution is 21mol / L;

[0034] Step 3), put the bottom turbidity I in step 1) into another reaction tank, add 5L of hydrochloric acid at the same time, the concentration of hydrochloric acid is 3mol / L, then add 50ml of hydrogen peroxide with a mass concentration of 30%, and stir for 2~3h After that, let it stand for 1 hour, and then drain the supernatant and add it to the reaction tank of the indium production system. The acidity of the obtained supernatant is PH=0.5, and the turbidity II at the bottom is discharged for storage.

[0035] The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com