A kind of stainless steel chemical polishing liquid and preparation method thereof

A chemical polishing, stainless steel technology, applied in the field of stainless steel chemical polishing liquid, can solve the problem that the working life of the polishing liquid needs to be improved, and achieve the effect of good polishing effect, convenient use and stable polishing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

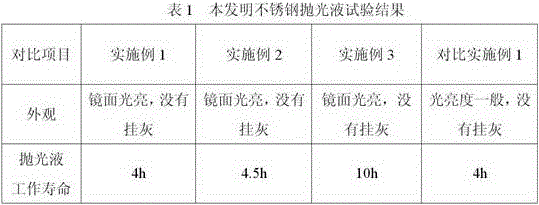

Examples

Embodiment 1

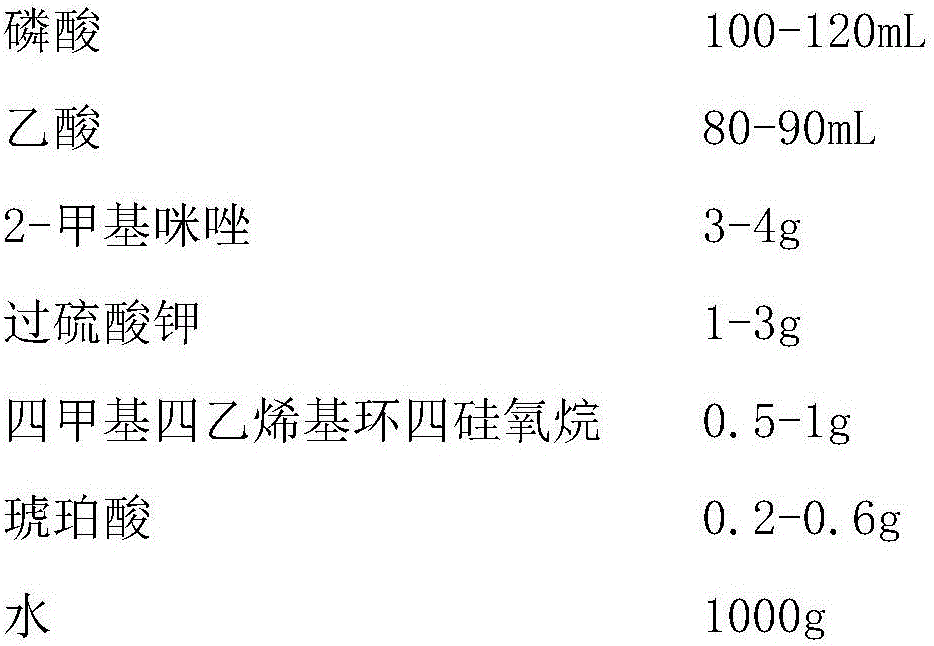

[0038] A chemical polishing liquid for stainless steel, made from the following raw materials:

[0039] Phosphoric acid 100mL

[0040] Acetic acid 90mL

[0041] 2-Methylimidazole 3g

[0042] Potassium persulfate 3g

[0043] Tetramethyltetravinylcyclotetrasiloxane 0.5g

[0044] Succinic acid 0. 6g

[0045] water 1000g

[0046] The mass percent concentration of phosphoric acid is 85%.

[0047] The preparation method of above-mentioned a kind of stainless steel chemical polishing liquid, comprises the following steps:

[0048] (1) According to the composition of the raw material formula, mix phosphoric acid and acetic acid, and fully stir to obtain semi-finished product A;

[0049] (2) According to the composition of the raw material formula, 2-methylimidazole, potassium persulfate, tetramethyltetravinylcyclotetrasiloxane, and succinic acid are added to water, and fully stirred until it is completely dissolved to prepare a semi-finished product B for use;

[0050] (3) Slo...

Embodiment 2

[0052] A chemical polishing liquid for stainless steel, made from the following raw materials:

[0053] Phosphoric acid 120mL

[0054] Acetic acid 80mL

[0055] 2-Methylimidazole 4g

[0056] Potassium persulfate 1g

[0057] Tetramethyltetravinylcyclotetrasiloxane 1g

[0058] Succinic acid 0. 2g

[0059] water 1000g

[0060] The mass percent concentration of phosphoric acid is 85%.

[0061] The preparation method of above-mentioned a kind of stainless steel chemical polishing liquid is the same as embodiment 1.

Embodiment 3

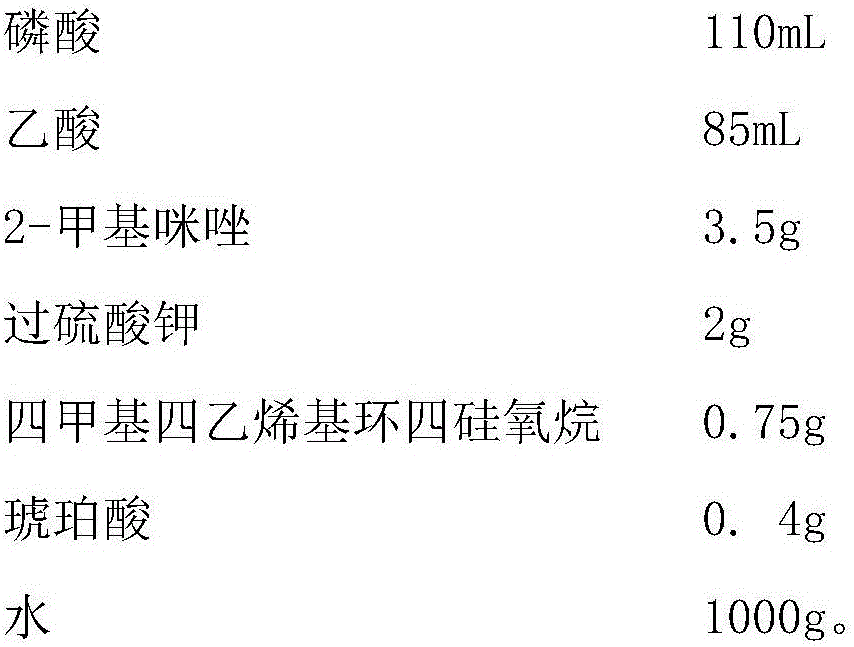

[0063] A stainless steel chemical polishing solution is characterized in that it is made of the following raw materials:

[0064] Phosphoric acid 110mL

[0065] Acetic acid 85mL

[0066] 2-Methylimidazole 3.5g

[0067] Potassium persulfate 2g

[0068] Tetramethyltetravinylcyclotetrasiloxane 0.75g

[0069] Succinic acid 0. 4g

[0070] water 1000g

[0071] The mass percent concentration of phosphoric acid is 85%.

[0072] The preparation method of above-mentioned a kind of stainless steel chemical polishing liquid is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com