Smokeless particle combustion machine

A burner and particle technology, which is applied in the direction of combustion method, combustion equipment, solid fuel combustion, etc., can solve the problems of insufficient combustion of combustion devices, low heat utilization efficiency, and the separation of net hot air and waste heat recovery devices, etc. , to achieve the effect of simple structure, high heat utilization efficiency and low smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are attached with accompanying drawings in detail as follows. The embodiments illustrated in the accompanying drawings are only used to illustrate the technical solution of the present invention , not to limit the present invention.

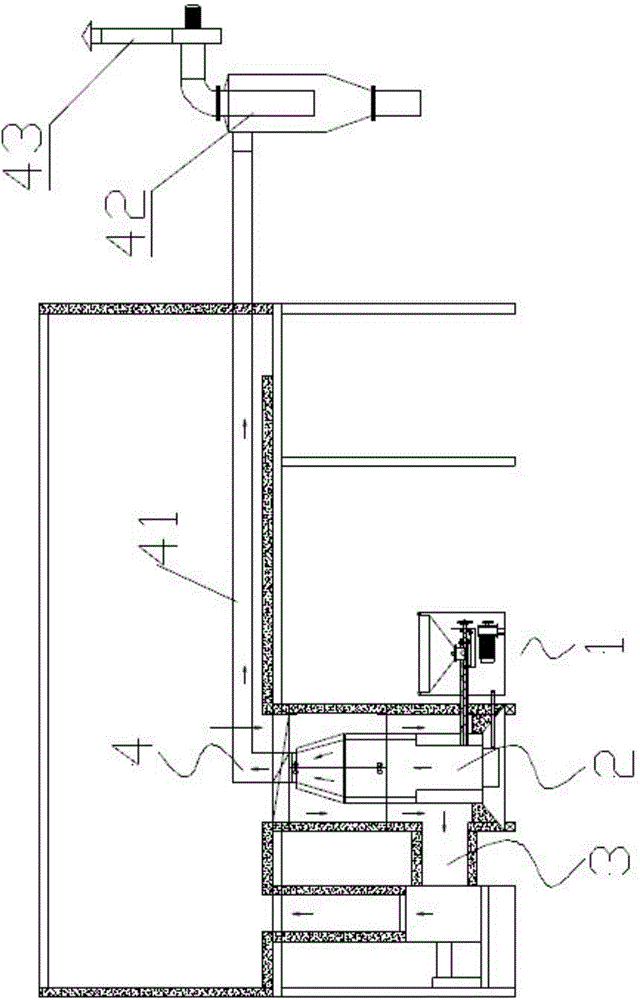

[0022] Such as figure 1 , a smokeless particle burner provided by the present invention, the smokeless particle burner includes a feeding device 1 , a burner 2 , a heat energy utilization system 3 and a waste heat recovery system 4 .

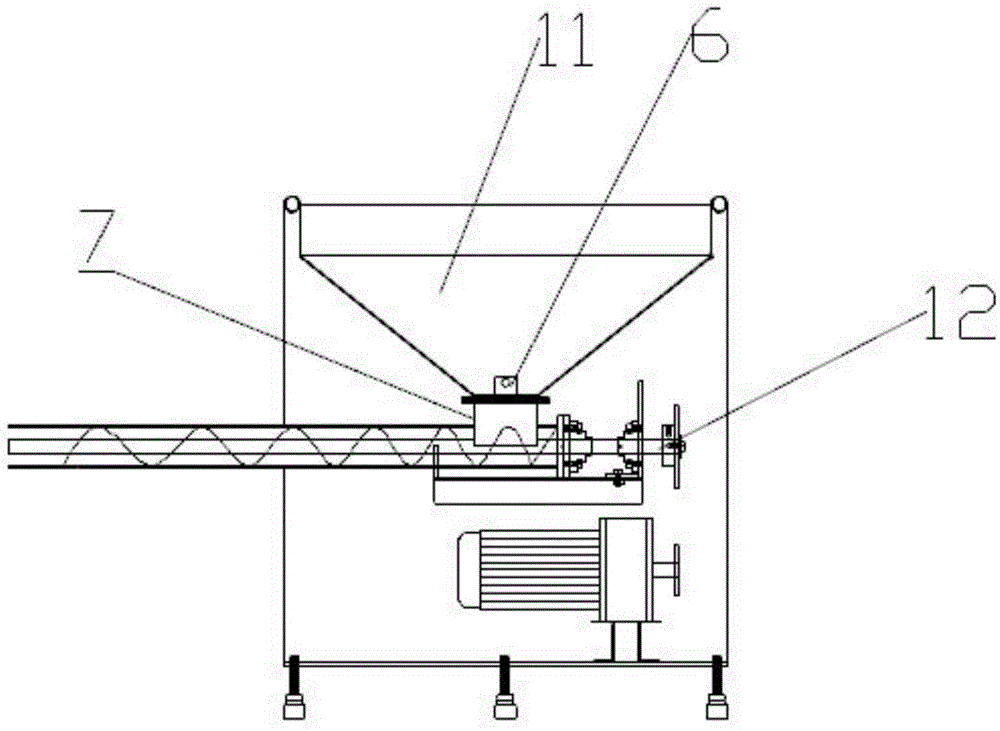

[0023] figure 2 As shown, the feeding device 1 includes a feeding hopper 11, and a screw automatic feeding device 12 at the bottom of the feeding hopper 11, and the screw automatic feeding device 12 extends to the burner 2;

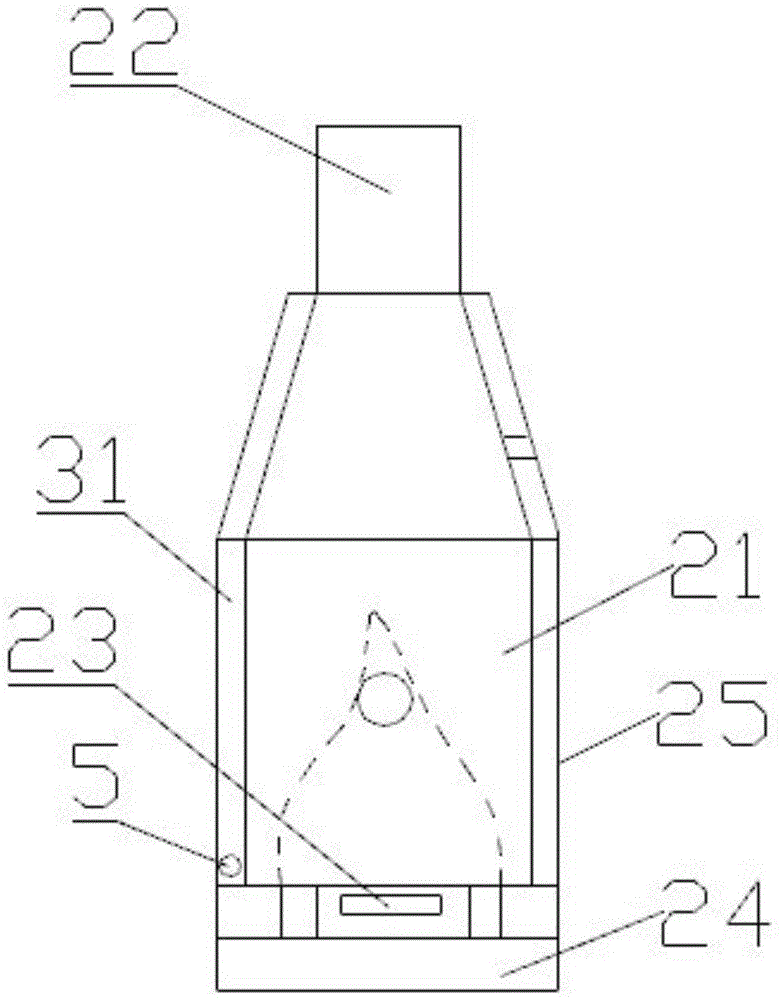

[0024] Such as image 3 The burner 2 shown includes a cyclone type combustion liner 21, the top of the liner 21 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com