Lightweight, simplified, high-stability and coaxial camera primary and secondary lens assembly and mounting method

A coaxial camera, high stability technology, applied in the direction of installation, camera, camera body, etc., can solve the problems of high complexity, heavy weight, etc., to improve assembly accuracy and efficiency, reduce assembly links, and improve overall accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

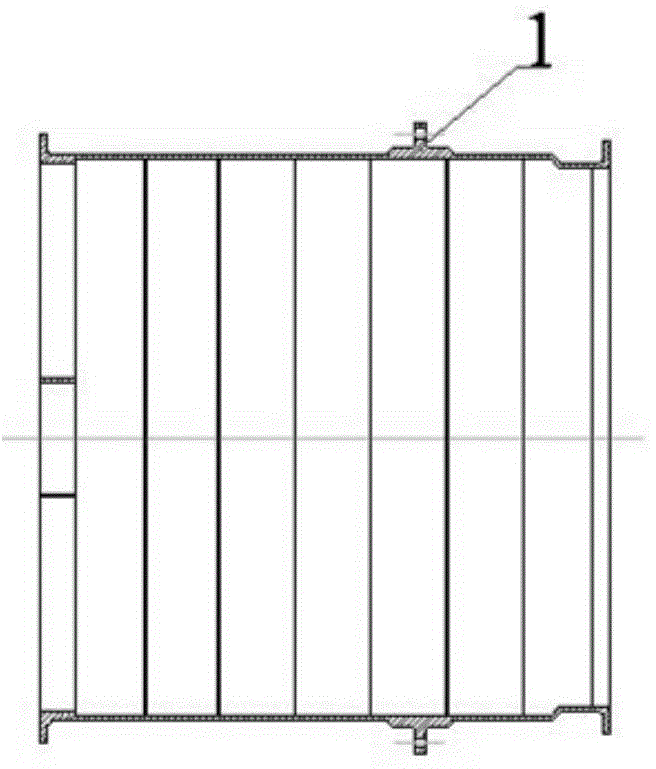

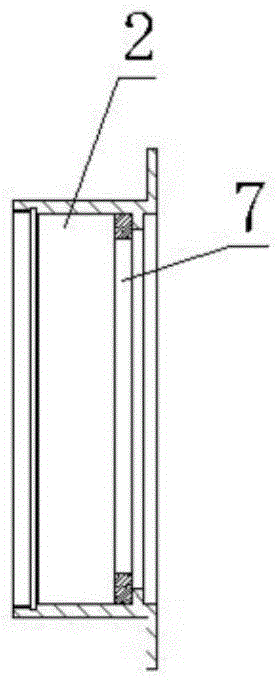

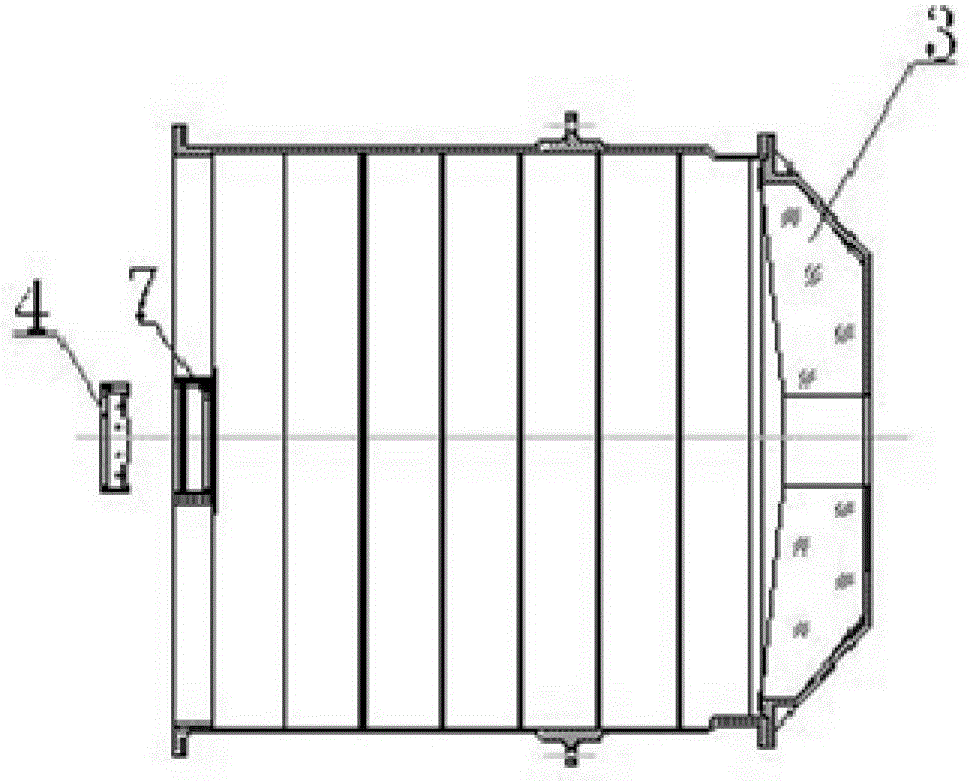

[0030] Such as figure 1 and Figure 4 As shown, the present invention is a lightweight, simplified and highly stable coaxial camera primary and secondary mirror components and installation method, including a load-bearing cylinder component 1, a coaxial camera primary mirror component 4, a secondary mirror component 5, and a metal nesting 2. Nested support 6 and multiple radial support rods 5, the number of radial support rods 5 is 4, and the metal nest 2 is as figure 2 As shown, it also includes a trimming pad 7, the load-bearing cylinder part 1, the nested support 6 and a plurality of radial support rods 5 are carbon fiber composite members, and the nested support 6 is an annular structure, which passes through multiple A radial support rod 5 is coaxially arranged at the center of the front flange of the bearing cylinder, and a metal nest 2 is fixed in the nest support 6; the metal nest 2 may be an indium steel nest. The metal nest 2 and the nest support 6 can be fixed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com