Blow molding equipment intelligent temperature control system and method based on DSP and FPGA

A technology of intelligent temperature control and equipment, which is applied in the direction of temperature control using electric methods, can solve the problems that cannot meet the requirements of multi-layer high-performance film blow molding, difficult to meet the requirements of blow molding, and time-consuming debugging, so as to improve stability Confidentiality of intellectual property rights, improvement of production efficiency and product quality, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings.

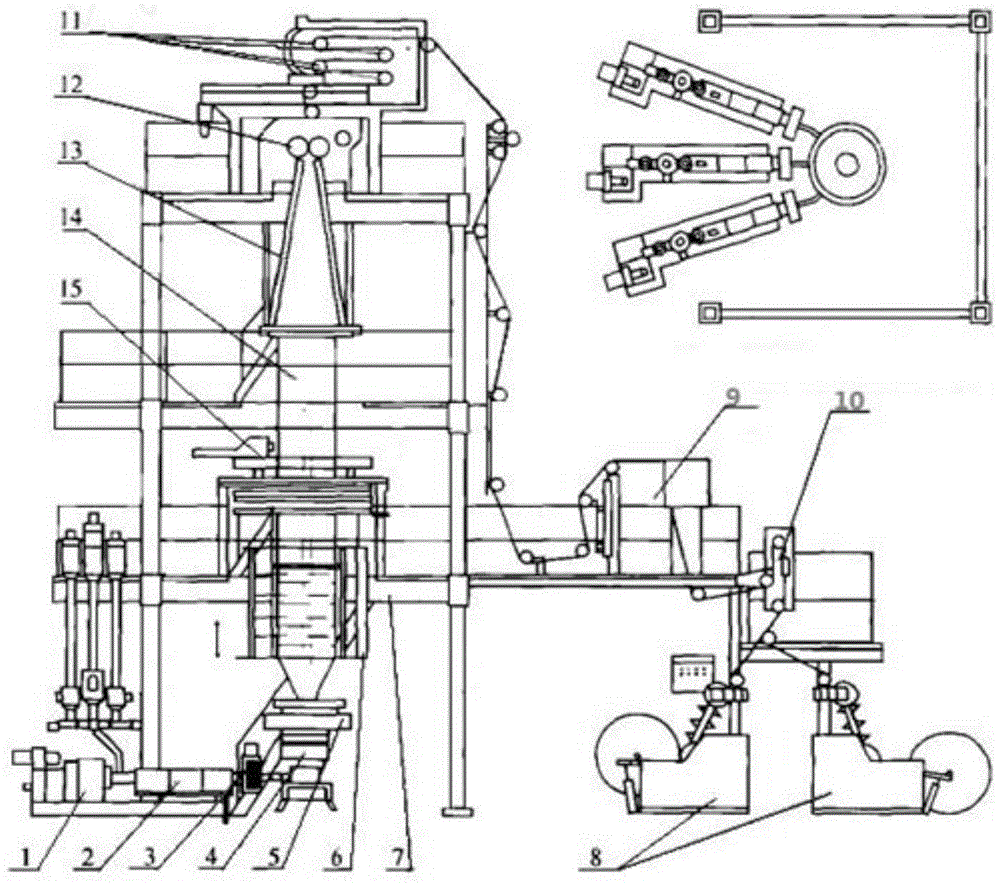

[0048] Such as figure 1 Shown is a schematic diagram of a multi-layer co-extrusion blown film unit, and the intelligent temperature control system provided by the present invention can be used in a multi-layer co-extrusion blown film unit. The multi-layer co-extrusion blown film unit is mainly composed of feeding system, extruder, die head, cooling device, film thickness measuring equipment, herringbone plate, traction roller, coiling device, monitoring and control system, etc. The control system and control method provided by the present invention can be used to control heating zones such as extruders and dies, realize precise temperature control of each heating zone, better meet the production requirements of blow molding units, and improve product quality.

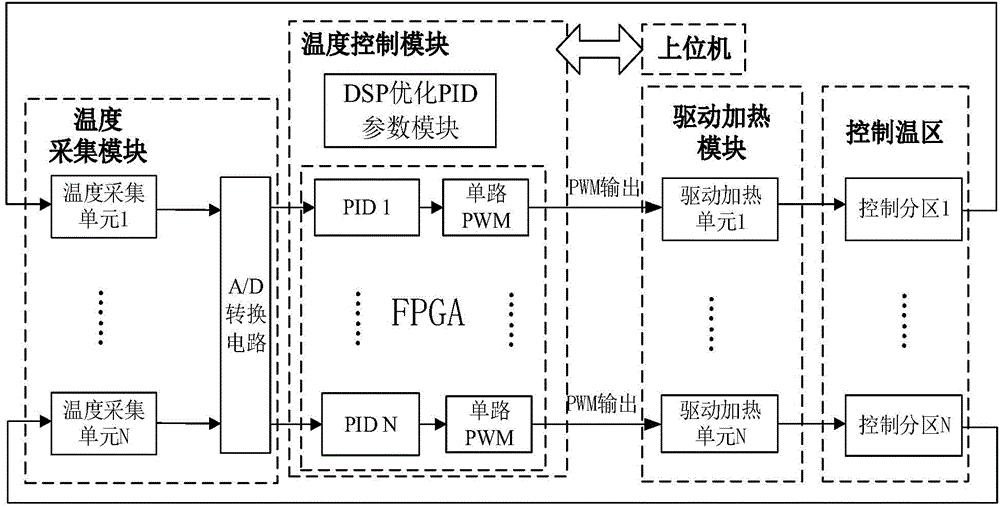

[0049] Such as figure 2 As shown, the intelligent temperature control system of blow molding equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com