Gas absorbing device for fuel element

A gas absorption and fuel element technology, which is applied to fuel elements, reactor fuel elements, measuring devices, etc., can solve the problems of hydrogen absorption damage to the coating material of fuel elements, small surface area for absorbing hydrogen tritium, and the strength of supporting structures. Risk of hydrogenation and breakage, increased gas absorption volume and surface area, simple effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

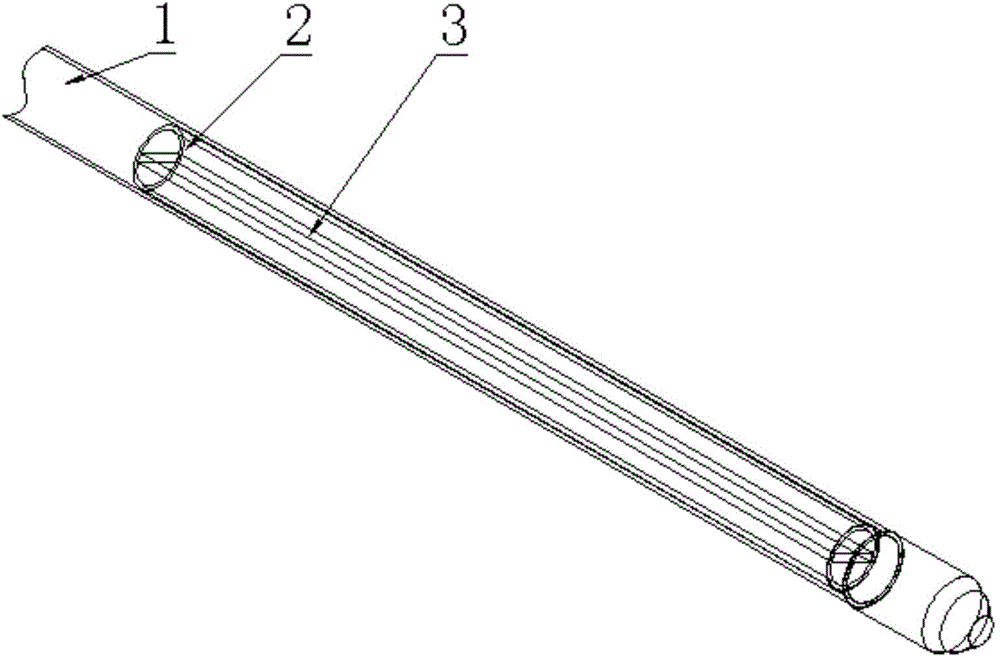

[0025] Such as figure 1 , figure 2 As shown, a fuel element gas absorbing device includes a fuel element coating material 1 with a cylindrical structure and a sheet-shaped gas absorbing structure 3 capable of absorbing hydrogen and hydrogen isotopes, wherein the sheet-shaped gas absorbing structure 3 is a flat plate structure , which is fixed inside the fuel element cladding material 1 through a cylindrical or spiral support structure 2, and a sheet-like gas-absorbing structure 3 is fixed on the upper or lower part of the fuel pellet area of the fuel element; the sheet-like gas-absorbing structure 3 is composed of Hydrogen and hydrogen isotope absorption materials such as zirconium alloys, ceramics or zirconium-aluminum alloys are coated with catalysts such as Ni and Pd on their surfaces.

Embodiment 2

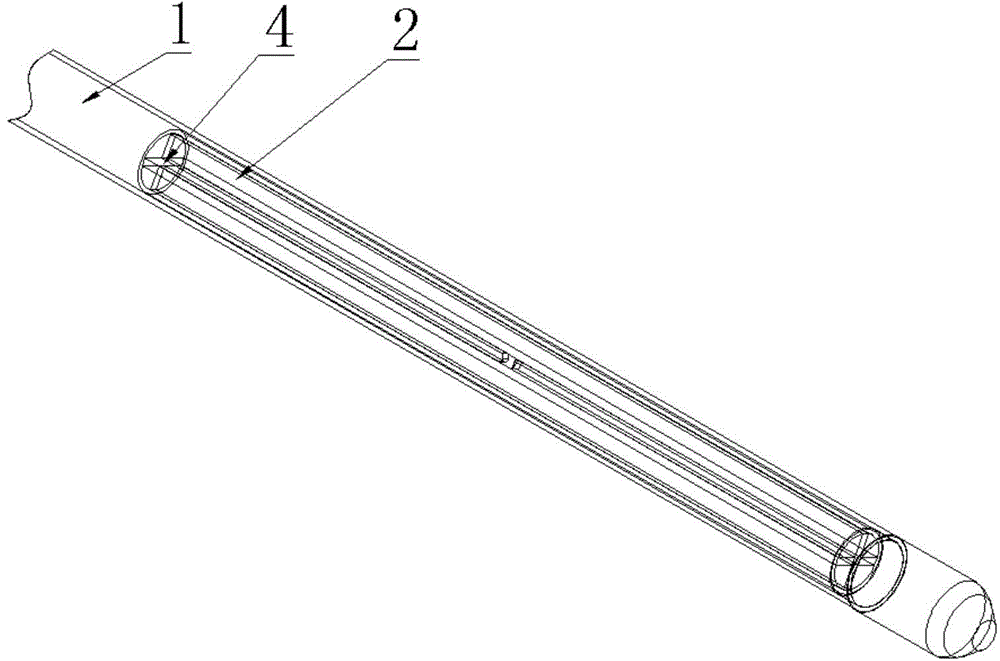

[0027] Such as image 3 , Figure 4 As shown, a fuel element gas absorption device includes a fuel element coating material 1 with a cylindrical structure and a cross-shaped gas absorption structure 4 capable of absorbing hydrogen and hydrogen isotopes, wherein the cross-shaped gas absorption structure 4 is two A cross-shaped plate structure formed by a vertical plate, which is fixed inside the fuel element cladding material 1 through a cylindrical or spiral support structure 2, and a cross-shaped gas absorption structure 4 is fixed on the upper part of the fuel pellet area of the fuel element Or the lower part; the cross-shaped gas absorption structure 4 is made of hydrogen and hydrogen isotope absorption materials such as zirconium alloys, ceramics or zirconium-aluminum alloys, and its surface is coated with catalysts such as Ni and Pd.

Embodiment 3

[0029] Such as Figure 5 , Figure 6 As shown, a fuel element gas absorption device includes a fuel element coating material 1 with a cylindrical structure and a helical gas absorption structure 5 capable of absorbing hydrogen and hydrogen isotopes, wherein the helical gas absorption structure 5 is directly fixed on the Inside the fuel element cladding material 1, the spiral gas absorbing structure 5 is fixed on the upper or lower part of the fuel pellet area of the fuel element; the cross-shaped gas absorbing structure A4 is made of hydrogen and tritium absorbing materials such as zirconium alloy, ceramics or zirconium aluminum alloy , coated with catalysts such as Ni and Pd on its surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com