A kind of production method of anti-crack solar module

A technology for solar modules and production methods, which is applied in the manufacturing of electrical components, semiconductor devices, final products, etc., can solve problems such as reducing the structural strength of modules, and achieve the effects of large thinning space, low attenuation, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

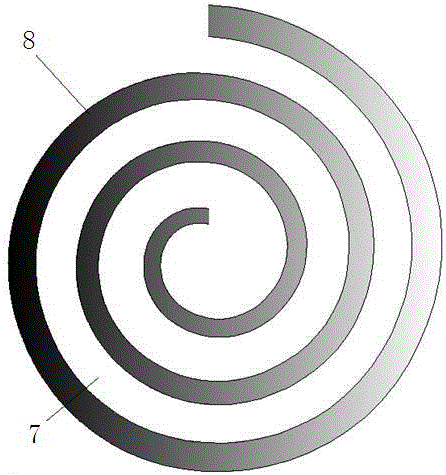

[0028] The solar cell layer 3 adopts 156 polycrystalline solar cell packaging 6*10 solar module layout, the substrate 1 is plexiglass, the first film layer 2 and the third film layer 5 are EVA film, and the second film layer 4 is polytetrafluoroethylene Vinyl. As attached in the manual image 3 As shown, the second film layer 4 is hollowed out with a spiral structure, and there are 60 spiral structures, which correspond to the solar cells one by one, with a thickness of 500 microns. Microns. The component production process is:

[0029] String welding: Solar cells are connected in a row through welding ribbons.

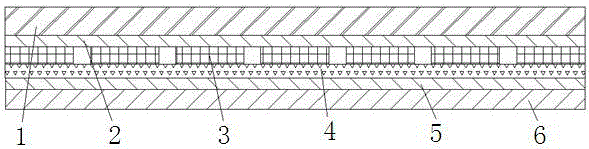

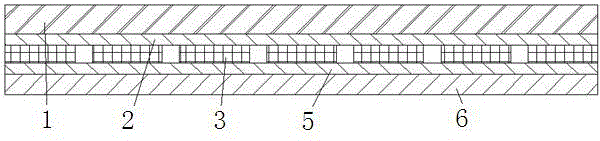

[0030] Plate assembly: Arrange the stringed solar cells on the laid glass and a layer of EVA on it, and connect multiple rows of solar cells in series through welding ribbons, so that all the cells are connected in series. Then lay a layer of polytetrafluoroethylene resin on the battery sheet, then lay a layer of EVA, and finally lay a layer of transparent back pl...

Embodiment 2

[0034] The solar cell layer 3 adopts 156 monocrystalline solar cell packaging 6*10 solar module layout, the substrate 1 is tempered glass, the first film layer 2 and the third film layer 5 are POE film, and the second film layer 4 is polyimide Amine resin. As attached in the manual Figure 4 As shown, the second film layer 4 is hollowed out in a grid structure with a thickness of 1000 microns, the width of the hollowed out area 7 of the grid structure is 800 microns, and the width of the non-hollowed area 8 of the grid structure is 800 microns. The component production process is:

[0035] String welding: Solar cells are connected in a row through welding ribbons.

[0036] Plate assembly: Arrange the stringed solar cells on the laid glass and a layer of POE on it, and connect multiple rows of solar cells in series through welding ribbons, so that all the cells are connected in series. Afterwards, a layer of polyimide resin is laid on the battery sheet, a layer of POE is lai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com