Control system and method of DELTA robots based on visual tracking

A visual tracking and control system technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of poor versatility and low versatility, and achieve the effect of simple setting, improved versatility, and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

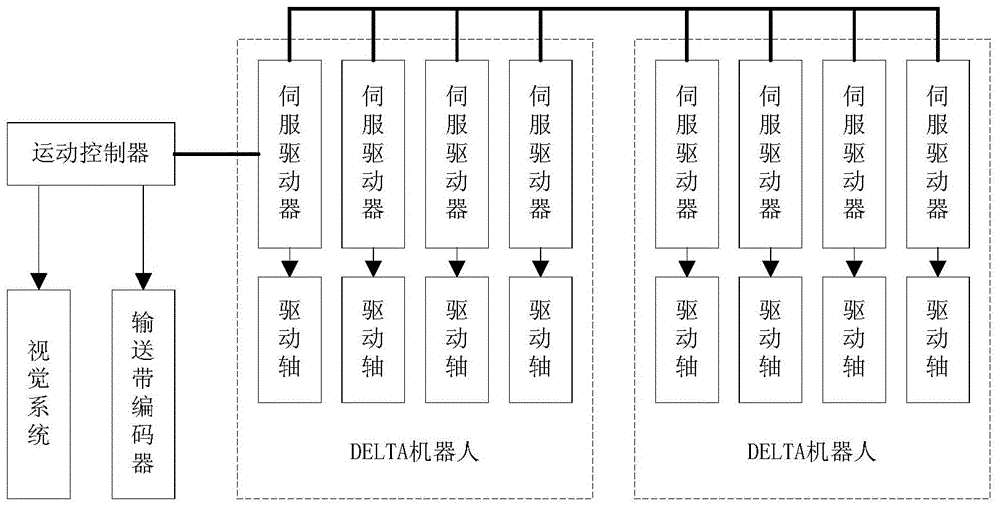

[0037] refer to figure 1 , a DELTA robot control system based on vision tracking, including a motion controller, a vision system, a conveyor belt encoder and two DELTA robots, each of which includes four servo drives and four drive shafts, each The driving shaft is controlled by a servo drive; all the above servo drives are connected in series, and the first servo drive is connected with the motion controller; the vision system and the conveyor belt encoder are connected with the motion controller.

[0038] This system can be realized by using a Sanmotion motion controller and a servo drive system based on SANYO DENKI. One Sanmotion motion controller has two DELTA robots, each DELTA robot has four drive axes, and the two DELTA robots share a vision system. location data. The DELTA robot determines its gripping position based on the position data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com