Method for producing TiCl4 by using low-TiO2-grade titanium slag

A technology of titanium slag and grade, applied in the direction of titanium halide, titanium tetrachloride, etc., can solve the problems of long production time and high cost, and achieve the effect of reducing production cost and improving comprehensive utilization level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

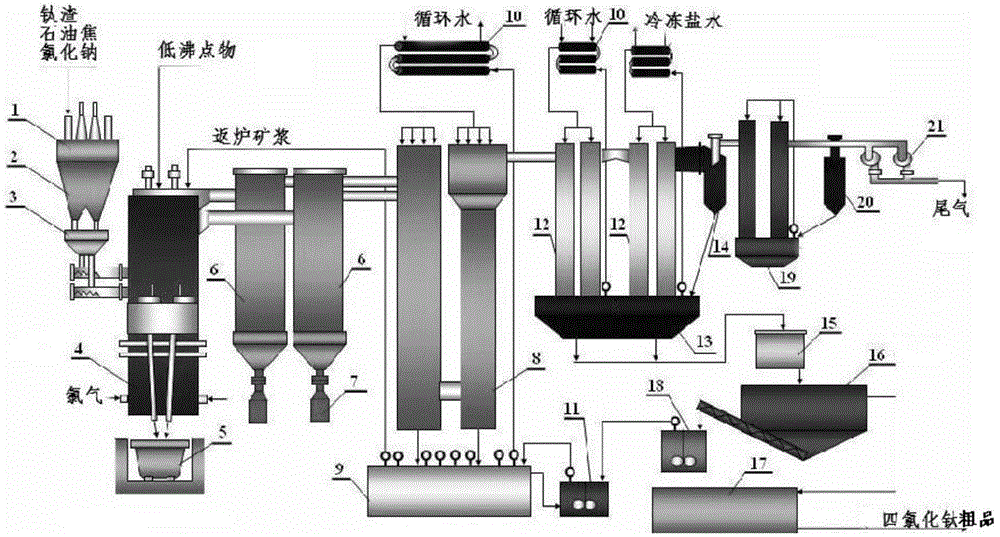

[0030] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0031] The powdered titanium slag, petroleum coke and sodium chloride loaded into the furnace top bunker 2 are prepared into a mixed furnace charge through a metering belt scale 1 in a set amount, and the furnace charge is added to the melting furnace through a feeding screw 3 at an appropriate speed. Salt chlorination furnace 4. Cl with a pressure of 60-120kpa 2 When passing into the molten salt layer at 700-750°C in the chlorination furnace, the molten salt will be strongly stirred, and at the same time, the 2 It is heated and dispersed in the molten salt medium, and the mixed charge added to the furnace is fully dispersed in the molten salt. The main reaction in the molten salt is: TiO 2 +2C+2Cl 2 =TiCl 4 +2CO; TiO 2 +C+2Cl 2 =TiCl 4 +CO 2 . Other components in titanium slag will also interact with Cl 2 Interaction to form FeC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com