Ionic exchange membrane electrolytic cell device for treating chemical production wastewater

An ionic membrane electrolytic cell, chemical production technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing sewage treatment time, low treatment efficiency, etc. The effect of processing efficiency, increasing the outflow area, and shortening the processing time of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

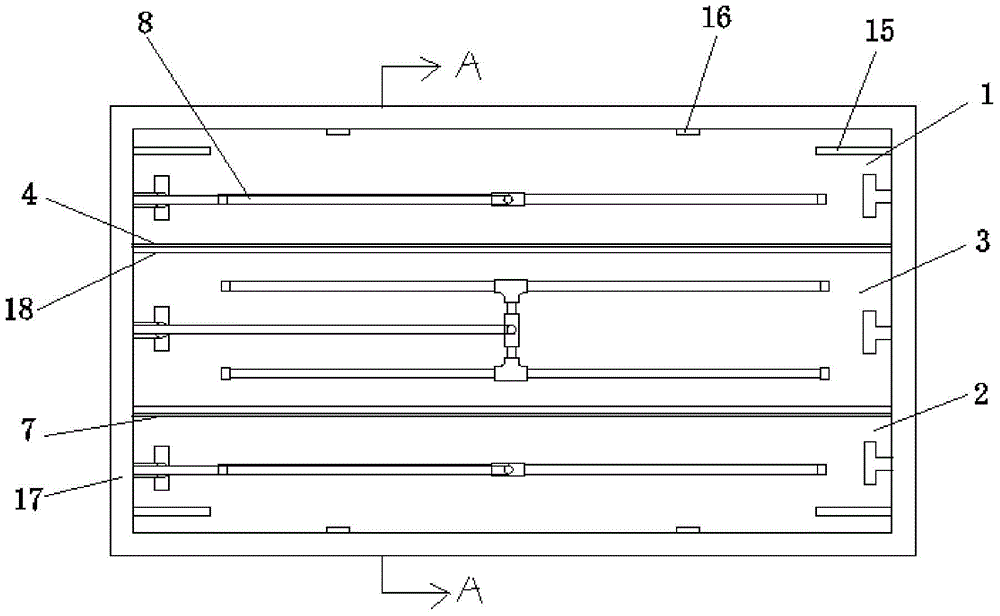

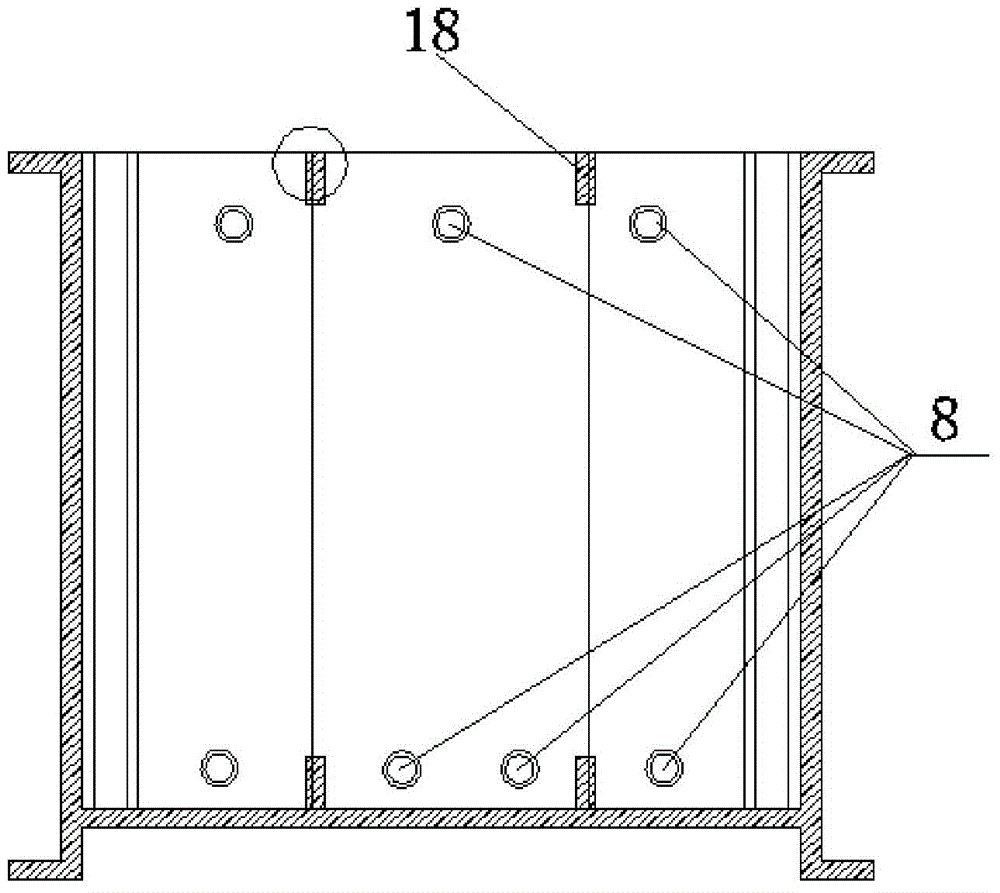

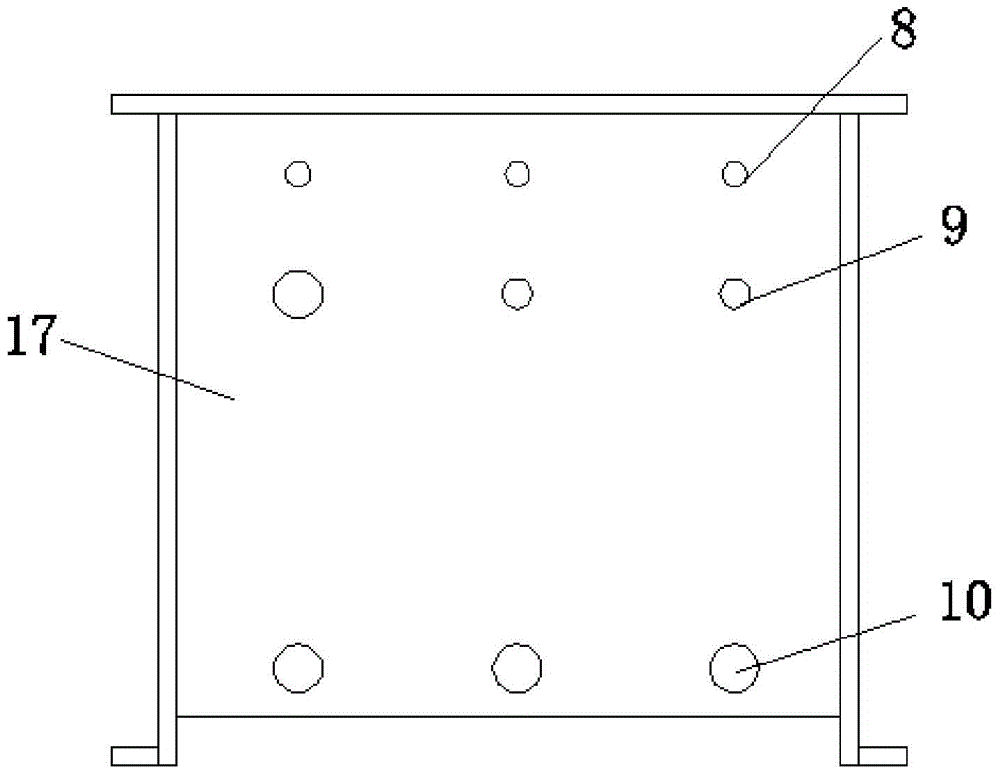

[0037] Such as Figure 1 to Figure 10 Shown, a kind of ionic membrane electrolyzer device for processing chemical industry production wastewater, this electrolyzer device is a three-chamber structure, includes waste water chamber 3, and the first fresh water chamber 1 and the second fresh water chamber 2 that are positioned at both sides of described waste water chamber, The waste water chamber 3 is separated from the first fresh water chamber 1 by a cationic membrane 4, and the side of the cationic membrane 4 near the waste water chamber 3 is provided with a back-shaped partition 18, and the side near the first fresh water chamber 1 is formed by The rubber pad frame 5 and the partition frame 6 are provided in sequence from the inside to the outside. The back-shaped partition 18, the cationic membrane 4, the rubber pad frame 5 and the partition frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com