Heteropolyacid ionic liquid and application of heteropolyacid ionic liquid in oxidative desulfurization

An ionic liquid and oxidative desulfurization technology, which is applied in the fields of refining oxygen-containing compounds, organic chemistry, chemical instruments and methods, etc., can solve problems such as difficulty in obtaining diesel oil and difficult removal of sulfur, and achieve short reaction time, high selectivity, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

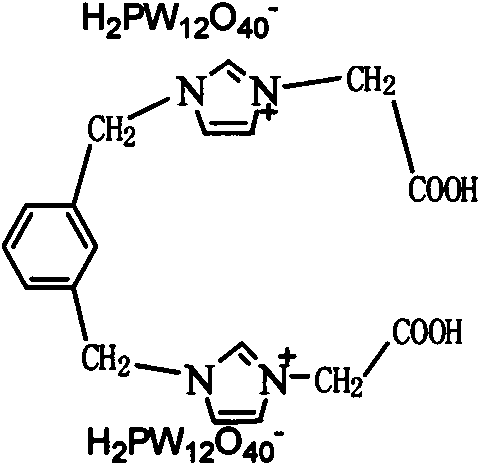

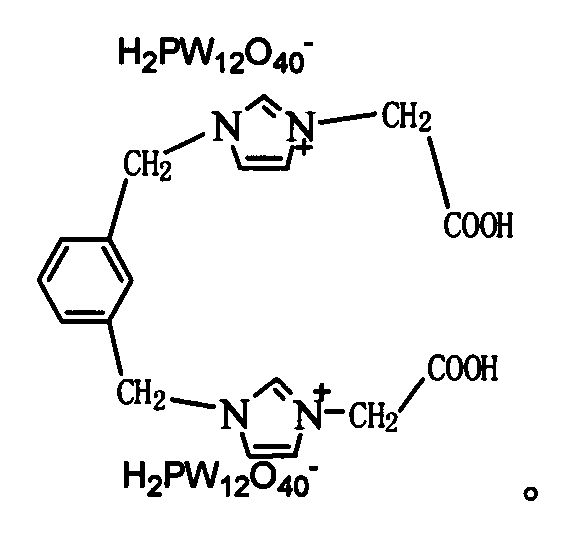

Image

Examples

Embodiment 1

[0025] 0.028g[C 18 h 20 N 4 o 4 ]H 2 PW 12 o 40 , 1,1'-[1,3-phenylenebis(methylene)]bis[3-(carboxymethyl)]-1H-imidazolium phosphotungstic acid, added to 15ml simulated diesel oil (where 4,6 dimethyldibenzothiophene, the sulfur content is 268 μg / g), then add 1.75ml H 2 o 2Aqueous solution (30% by mass), after magnetic stirring at 298K and normal pressure for 25min, take 1ml of oil in the upper layer and add 1ml of extractant N-methylpyrrolidone, shake fully and centrifuge in a centrifuge. After centrifugation, take the upper liquid and measure its sulfur content in a coulometric analyzer to be 48 μg / g, and the desulfurization rate is 82%. After the desulfurization is completed, the ionic liquid phase is separated, the ionic liquid is separated by simply pouring the ionic liquid phase, and it is vacuum-dried at 80° C. to obtain a regenerated ionic liquid, which can be reused.

Embodiment 2

[0027] 0.028g[C 18 h 20 N 4 o 4 ]H 2 PW 12 o 40 , 1,1'-[1,3-phenylenebis(methylene)]bis[3-(carboxymethyl)]-1H-imidazolium phosphotungstic acid, added to 15ml simulated oil (where 4,6 dimethyldibenzothiophene, the sulfur content is 226 μg / g), then add 1.75ml H 2 o 2 Aqueous solution (30%), after magnetic stirring at 303K and normal pressure for 25min, take 1ml of oil from the upper layer, add 1ml of extractant N-methylpyrrolidone, shake fully and centrifuge in a centrifuge. After centrifugation, take the upper layer liquid and measure its sulfur content in a coulometric analyzer to be 27 μg / g, and the desulfurization rate is 88%. After the desulfurization is completed, the ionic liquid phase is separated, the ionic liquid is separated by simply pouring the ionic liquid phase, and it is vacuum-dried at 80° C. to obtain a regenerated ionic liquid, which can be reused.

Embodiment 3

[0029] 0.028g[C 18 h 20 N 4 o 4 ]H 2 PW 12 o 40 , 1,1'-[1,3-phenylenebis(methylene)]bis[3-(carboxymethyl)]-1H-imidazolium phosphotungstic acid, added to 15ml simulated oil (where 4,6 dimethyldibenzothiophene, the sulfur content is 268 μg / g), then add 1.75ml H 2 o 2 Aqueous solution (30%), after magnetic stirring at 308K and normal pressure for 25min, take 1ml of oil from the upper layer and add 1ml of extractant N-methylpyrrolidone, shake fully and centrifuge in a centrifuge. After centrifugation, take the upper layer liquid and measure its sulfur content in a coulometric analyzer to be 17 μg / g, and the desulfurization rate is 93.7%. After the desulfurization is completed, the ionic liquid phase is separated, the ionic liquid is separated by simply pouring the ionic liquid phase, and it is vacuum-dried at 80° C. to obtain a regenerated ionic liquid, which can be reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com