Polymer with bidirectional reversible shape memory effect and preparation method thereof

A memory effect and polymer technology, applied in smart materials and their preparation, polymer materials with bidirectional reversible shape memory effect and their preparation, can solve the problem of inappropriate quantitative mechanism research, destruction of crystallization, and adjustable phase transition temperature problems such as poor performance, to achieve the effects of simple preparation method, good stability and good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] raw material:

[0047] a) polyethylene glycol diacrylate (PEGDA): Mw=8000, Alfa Aesar company;

[0048] b) Cyclohexyl methacrylate (CMA): Sigma-Aldrich;

[0049] c) Benzoyl peroxide (BPO): Aladdin Reagent (Shanghai) Co., Ltd.;

[0050] Preparation:

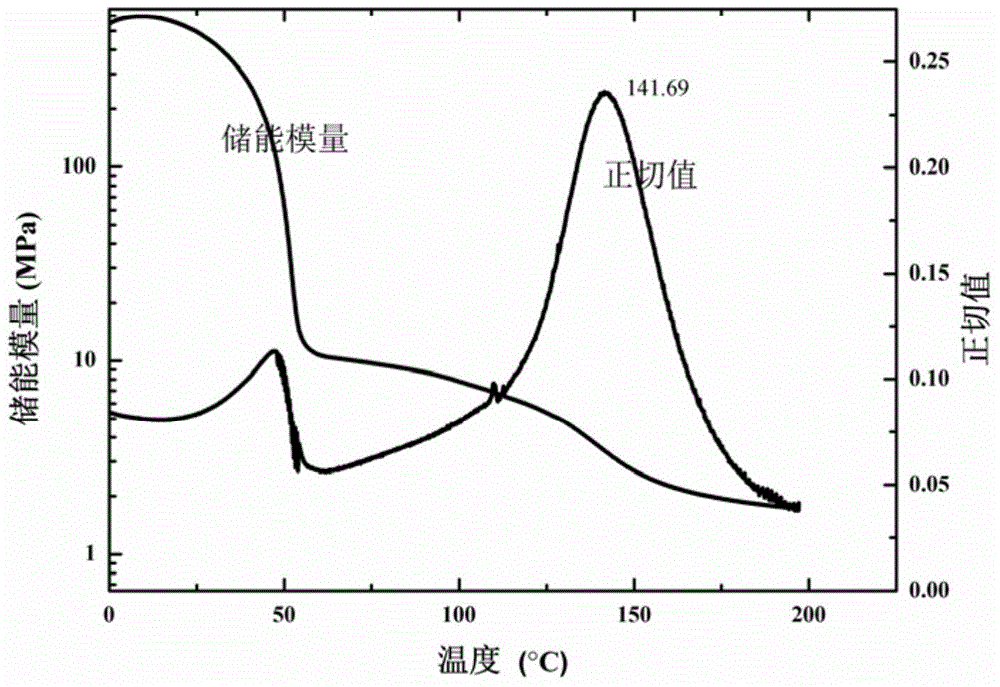

[0051] Prepared by bulk polymerization: weigh a certain amount of polyethylene glycol diacrylate and cyclohexyl methacrylate (the mass ratio of PEGDA to CMA is 3:1), add benzoyl peroxide (the amount of which is the system 3% of the total mass), dissolved at 70°C, stirred evenly, poured into a sealed glass tank, and cured at 100°C for 2 to 3 hours. The DMA test results of the crystalline melting temperature and glass transition temperature of the obtained polymer are as follows figure 1 .

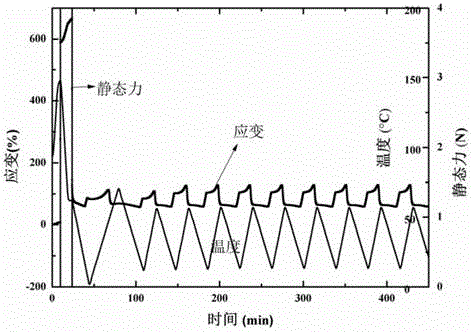

[0052] Characterization of double shape memory: heat the polymer to 156°C, apply a force of 1N to stretch it, cool it to 56°C under this tension, and remove the tension. This process is a programmed deformation process. Then continu...

Embodiment 2

[0054] raw material:

[0055] d) Polyethylene glycol diacrylate (PEGDA): Mw=8000, Alfa Aesar company;

[0056] e) Cyclohexyl methacrylate (CMA): Sigma-Aldrich;

[0057] f) tricyclodecane dimethanol diacrylate (TDD): Sigma-Aldrich company;

[0058] g) Benzoyl peroxide (BPO): Aladdin Reagent (Shanghai) Co., Ltd.;

[0059] Preparation:

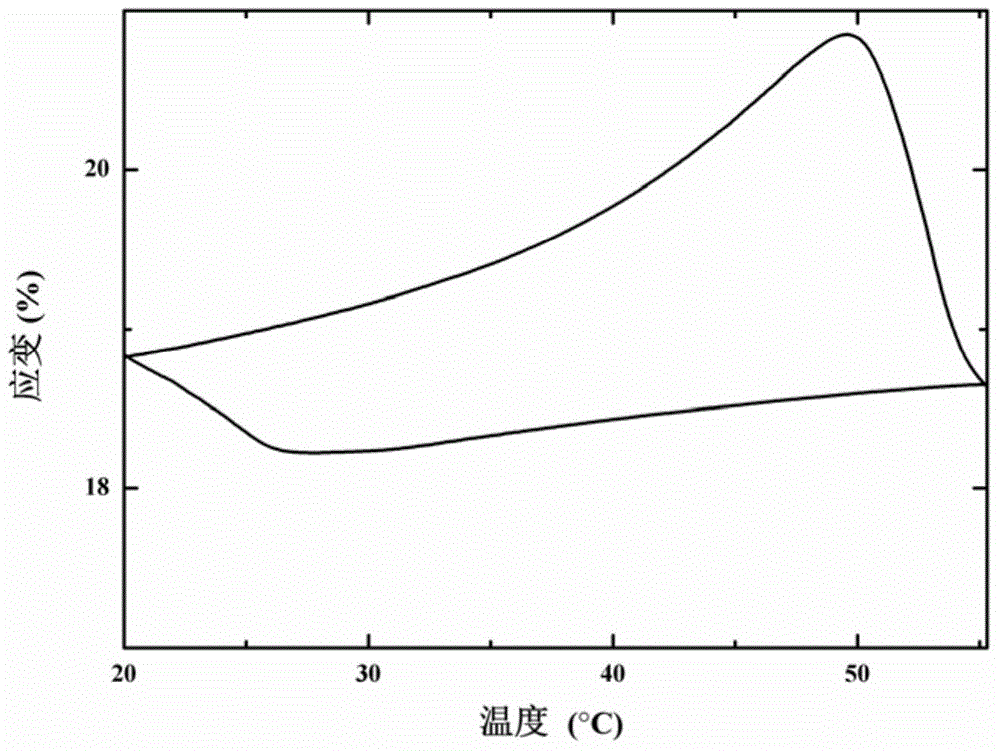

[0060] Prepared by bulk polymerization: weigh a certain amount of polyethylene glycol diacrylate, cyclohexyl methacrylate and tricyclodecane dimethanol diacrylate (wherein the mass ratio of PEGDA to CMA and TDD is 6:1:2 ), add benzoyl peroxide (the addition amount is 3% of the total mass of the system), dissolve it at 70°C, stir evenly, pour it into a sealed glass tank, and solidify at 100°C for 2-3h. The DMA test results of the crystalline melting temperature and glass transition temperature of the obtained polymer are as follows image 3 .

[0061] Characterization of double shape memory: heat the polymer to 170°C, apply a force of 2N to ...

Embodiment 3

[0063] raw material:

[0064] h) Polyethylene glycol diacrylate (PEGDA): Mw=8000, Alfa Aesar company;

[0065] i) cyclohexyl methacrylate (CMA): Sigma-Aldrich company;

[0066] j) Benzoyl peroxide (BPO): Aladdin Reagent (Shanghai) Co., Ltd.;

[0067] Preparation:

[0068] Prepared by bulk polymerization: weigh a certain amount of polyethylene glycol diacrylate and cyclohexyl methacrylate (wherein the mass ratio of PEGDA to CMA is 2:1), add benzoyl peroxide (the amount added is the total amount of the system) 3% of the mass), dissolve it at 70°C, stir it evenly, pour it into a sealed glass tank, and cure it at 100°C for 2 to 3 hours. The DMA test results of the crystalline melting temperature and glass transition temperature of the obtained polymer are as follows Figure 5 .

[0069] Characterization of double shape memory: heat the polymer to 170°C, apply a force of 2N to stretch it, cool it to 56°C under this tension, and remove the tension. This process is a programmed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com