Preparation method of high-performance magnetic polyurethane elastomer composite material

A polyurethane elastomer and composite material technology, applied in the direction of the magnetism of organic materials/organic magnetic materials, can solve the problems of simultaneous optimization of mechanical properties and magnetic properties, so as to improve the mechanical properties and magnetic properties, and improve the uniformity of dispersion performance, improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

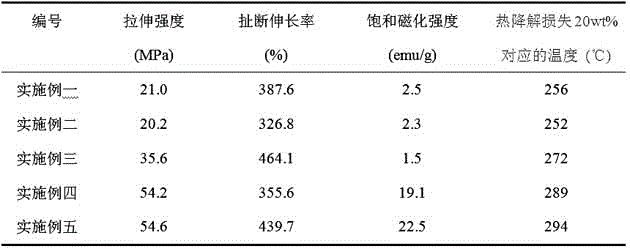

Examples

Embodiment 1

[0026] A method for preparing a high-performance magnetic polyurethane elastomer composite material, comprising the steps of:

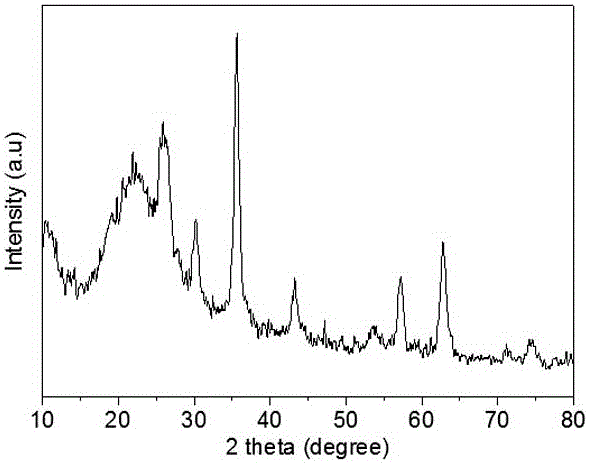

[0027] 1) Preparation of stable graphene@Fe 3 o 4 organic magnetic liquid;

[0028] a. Under ice bath conditions, add 2g of natural flake graphite and 2g of sodium nitrate into 46ml of concentrated sulfuric acid, and stir vigorously at a speed of 600r / min for 30min; further add 6g of potassium permanganate at a speed of 0.5g / min into the mixed solution of the above three substances, and then vigorously stirred at a speed of 600r / min for 60min; transferred the mixed solution of the above four substances to a water bath at 45°C, stirred at a speed of 400r / min for 4h, and then deionized 80ml Add water to the mixture of the above four substances, and then transfer it to an oil bath at 95°C; when the temperature of the reaction solution reaches 95°C, add 200ml of deionized water in a line, and then add 16ml of deionized water drop by drop 30% hydrogen p...

Embodiment 2

[0037] A method for preparing a high-performance magnetic polyurethane elastomer composite material, comprising the steps of:

[0038] 1) Preparation of stable graphene@Fe 3 o 4 organic magnetic liquid;

[0039] a. Under ice bath conditions, add 2g of natural flake graphite and 2g of sodium nitrate into 46ml of concentrated sulfuric acid, and stir vigorously at a speed of 600r / min for 30min; further add 6g of potassium permanganate at a speed of 0.5g / min into the mixed solution of the above three substances, and then vigorously stirred at a speed of 600r / min for 60min; transferred the mixed solution of the above four substances to a water bath at 45°C, stirred at a speed of 400r / min for 4h, and then deionized 80ml Add water to the mixture of the above four substances, and then transfer it to an oil bath at 95°C; when the temperature of the reaction solution reaches 95°C, add 200ml of deionized water in a line, and then add 16ml of deionized water drop by drop 30% hydrogen p...

Embodiment 3

[0048] A method for preparing a high-performance magnetic polyurethane elastomer composite material, comprising the steps of:

[0049] 1) Preparation of stable graphene@Fe 3 o 4 organic magnetic liquid;

[0050] a. Under ice bath conditions, add 2g of natural flake graphite and 2g of sodium nitrate into 46ml of concentrated sulfuric acid, and stir vigorously at a speed of 600r / min for 30min; further add 6g of potassium permanganate at a speed of 0.5g / min into the mixed solution of the above three substances, and then vigorously stirred at a speed of 600r / min for 60min; transferred the mixed solution of the above four substances to a water bath at 45°C, stirred at a speed of 400r / min for 4h, and then deionized 80ml Add water to the mixture of the above four substances, and then transfer it to an oil bath at 95°C; when the temperature of the reaction solution reaches 95°C, add 200ml of deionized water in a line, and then add 16ml of deionized water drop by drop 30% hydrogen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com