Phosphorus-containing reaction-type fire retardant as well as synthesis method and application thereof

A technology of reactive flame retardants and synthetic methods, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as easy decomposition, injury, and life safety threats, and achieve Improved flame retardant performance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under nitrogen protection, 43.6g of DOPO, 13.4g of m-phthalaldehyde and 60ml of toluene were sequentially added to a 500ml single-necked flask equipped with a condenser tube and a magnetic stirring bar. Stir vigorously, heat to 110°C, keep the toluene in a reflux state, and keep this condition for 5h. Cool to room temperature, filter, collect the precipitate, and continue to wash three times with toluene. Put the product into a vacuum oven to evacuate, heat to 60° C., and hold the pressure for 8 hours; cool to room temperature to obtain 51.3 g of white diDOPO-MDCA product (90% yield).

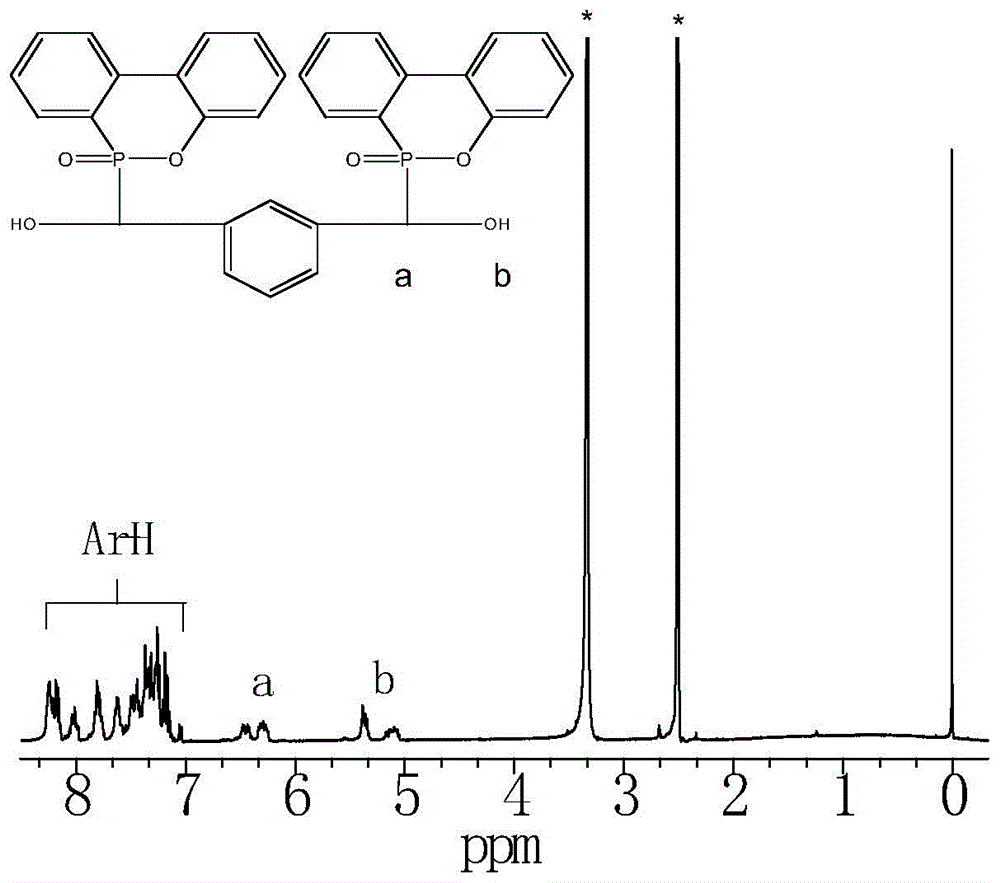

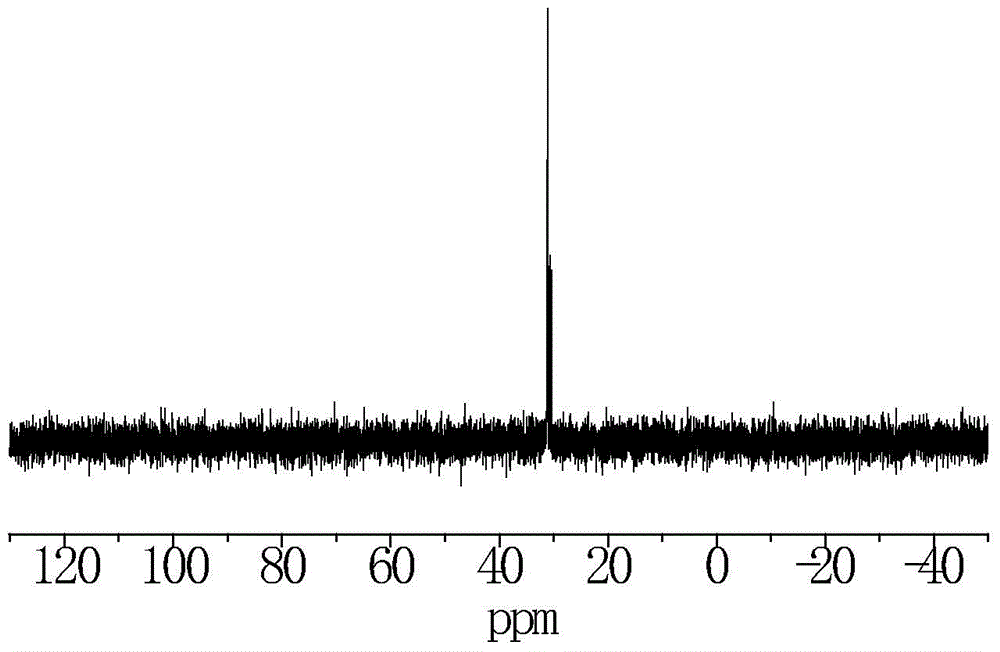

[0028] The product was determined by NMR 1 H NMR ( figure 1 )and 31 P NMR ( figure 2 ), 1 H NMR (ppm, DMSO-d 6 ), δ=8.29~7.03ppm (20H, Ar-H), 6.47~6.24ppm (2H, =CH-), 5.39~5.05ppm (2H, OH); 31 P NMR (ppm, DMSO-d 6 ), δ=31.02.

Embodiment 2

[0030] Under nitrogen protection, 43.6 g of DOPO, 13.4 g of m-phthalaldehyde and 285 ml of toluene were sequentially added to a 500 ml one-necked flask equipped with a condenser tube and a magnetic stirring bar. Stir vigorously, heat to 130°C, keep the toluene in a reflux state, and keep this condition for 5h. Cool to room temperature, filter, collect the precipitate, and continue to wash three times with toluene. Put the product into a vacuum oven to evacuate, heat to 80° C., and hold the pressure for 8 hours; cool to room temperature to obtain 51.3 g of white diDOPO-MDCA product (90% yield).

Embodiment 3

[0032] Under nitrogen protection, 43.6g of DOPO, 13.4g of m-phthalaldehyde and 200ml of toluene were sequentially added to a 500ml single-necked flask equipped with a condenser tube and a magnetic stirring bar. Stir vigorously, heat to 120°C, keep the toluene in a reflux state, and keep this condition for 5h. Cool to room temperature, filter, collect the precipitate, and continue to wash three times with toluene. Put the product into a vacuum oven to evacuate, heat to 70° C., and hold the pressure for 8 hours; cool to room temperature to obtain 51.3 g of white diDOPO-MDCA product (90% yield).

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com