A corn active peptide additive for cell culture medium

A technology of active peptides and additives, applied in the field of cell culture medium additives, can solve the problems of cell apoptosis, destroy cell membrane structure, change cell shape, etc., and achieve the effects of low endotoxin content, promotion of cell proliferation, and high enzymatic hydrolysis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

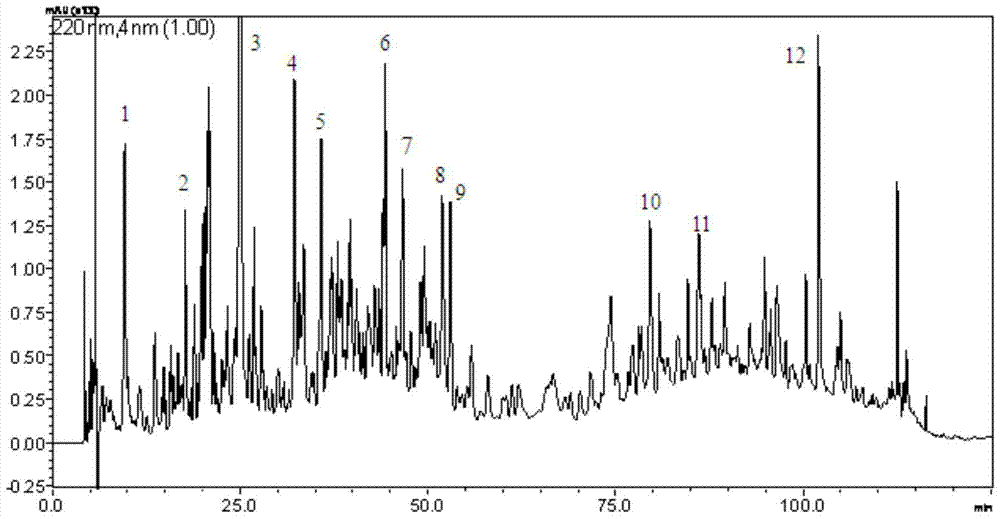

[0049] 1. Enzymatic treatment

[0050] Add 12 times deionized water to corn yellow powder with protein content ≥ 60%, mix well, heat up to 90°C, keep warm for 15-20 minutes, and when the temperature is lowered to 55°C, adjust the pH value of the protein solution to 7-8 , adding a compound non-specific protease mixed with neutral protease NEUTRASE O.D.L (Novozymes) and alkaline protease ALKALINE PROTEASECONCENTRATE (DSM Company) to the protein solution with an enzyme amount of 4000 units per gram of protein (wherein The enzyme amount of NEUTRASE O.D.L and alkaline protease ALKALINE PROTEASECONCENTRATE is 2000 units), and the first enzymolysis treatment was incubated at 55°C for 2.5 hours to obtain the first enzymolysis solution; the pH value of the first enzymolysis solution was adjusted to After 7.5 to 8.5, add carboxypeptidase ACCELERZYMECPG (DSM company) to the first enzymatic hydrolysis solution with an enzyme amount of 2000 units per gram of protein, and incubate at 50°C f...

Embodiment 2

[0069] The enzymatic hydrolysis treatment is specifically as follows: add 9 times deionized water to corn yellow powder with protein content ≥ 60%, mix well, heat up to 90-95°C, keep warm for 55-60 minutes, and then cool down to 50-55°C , adjust the pH of the protein solution to be 7-8, add papain (Nanning Pangbo Bioengineering Co., Ltd.) and bromelain (Nanning Pangbo Biological Engineering Co., Ltd.) Company) mixed compound non-specific protease (the enzyme amounts of papain and bromelain are 1000 units and 1500 units respectively), and the first enzymolysis treatment was incubated at 50-55°C for 1.5 hours to obtain the first enzymolysis solution; after adjusting the pH value of the first enzymolysis solution to 8-9, then add carboxypeptidase Validase FP Conc. (DSM company) and Flavor protease FLAVOURZYME500MG (Novozymes) is a composite specific protease (in which the enzyme amount of carboxypeptidase ACCELERZYME CPG and flavor protease FLAVOURZYME500MG are both 1500 units), ...

Embodiment 3

[0072] The enzymatic hydrolysis treatment is specifically: add 10 times deionized water to corn yellow powder with protein content ≥ 60%, mix well, heat up to 95°C, keep warm for 35-40 minutes, cool down to 45-50°C, adjust The pH value of the protein solution is 7-8, and the neutral protease Validase BNP-L (DSM company), alkaline protease Alcalase2.4L (Novozymes) is added to the protein solution with an enzyme amount of 6000 units per gram of protein. company), papain (Nanning Pangbo Bioengineering Co., Ltd.) and bromelain (Nanning Pangbo Biological Engineering Co., Ltd.) , papain and bromelain (the enzyme amounts of 2000 units, 2000 units, 1000 units and 1000 units respectively) were incubated at 45-50°C for the first enzymolysis treatment for 3 hours to obtain the first enzymolysis solution; After the pH value of the enzymolysis solution is 5.5, add flavor protease MAXZPRO XF (DSM company) to the first enzymolysis solution with an enzyme amount of 2000 units per gram of prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com