Directional solidifying preparation method of lotus-shaped porous aluminum

A directional solidification, lotus-shaped porous technology, which is applied in the field of directional solidification and preparation of lotus-shaped porous aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

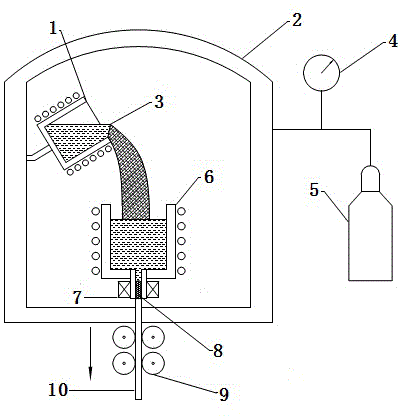

Method used

Image

Examples

Embodiment 1

[0027] After cleaning and removing 2kg of electrolytic aluminum with a purity of more than 99.9%, bake it in a holding furnace at 200°C for 2 to 4 hours to fully degas, place a melting crucible and a holding crucible in the vacuum directional solidification furnace, and then put the into the vacuum directional solidification furnace, close the furnace door of the vacuum directional solidification furnace, lock the safety lock of the furnace door, turn on the vacuum pump, and evacuate to 10 -1 Below Pa; turn on the cooling circulating water, turn on the heating power of the induction coil for heating the outer layer of the melting crucible, turn on the electricity to heat, and heat the electrolytic aluminum to 680°C. After the electrolytic aluminum in the melting crucible is completely melted, turn off the vacuum system and fill it with 0.5 MPa of hydrogen with a purity of 99.99%, heat preservation and pressure for 15 minutes; heat the graphite heater on the outer layer of the h...

Embodiment 2

[0030] After cleaning and removing 2kg of electrolytic aluminum with a purity of more than 99.9%, bake it in a holding furnace at 200°C for 2 to 4 hours to fully degas, place a melting crucible and a holding crucible in the vacuum directional solidification furnace, and then put the into the vacuum directional solidification furnace, close the furnace door of the vacuum directional solidification furnace, lock the safety lock of the furnace door, turn on the vacuum pump, and evacuate to 10 -1 Below Pa; turn on the cooling circulating water, turn on the heating power of the induction coil for heating the outer layer of the melting crucible, turn on the electricity to heat, and heat the electrolytic aluminum to 700°C. After the electrolytic aluminum in the melting crucible is completely melted, turn off the vacuum system and fill it with Purity of 99.99% hydrogen 1.0MPa, heat preservation and pressure for 20 minutes; heat the graphite heater on the outer layer of the heat preserv...

Embodiment 3

[0033] After cleaning and removing 2kg of electrolytic aluminum with a purity of more than 99.9%, bake it in a holding furnace at 200°C for 2 to 4 hours to fully degas, place a melting crucible and a holding crucible in the vacuum directional solidification furnace, and then put the into the vacuum directional solidification furnace, close the furnace door of the vacuum directional solidification furnace, lock the safety lock of the furnace door, turn on the vacuum pump, and evacuate to 10 -3 Below Pa; turn on the cooling circulating water, turn on the heating power of the induction coil for heating the outer layer of the melting crucible, turn on the electricity to heat, and heat the electrolytic aluminum to 720°C. After the electrolytic aluminum in the melting crucible is completely melted, turn off the vacuum system and fill it with Purity of 99.99% hydrogen 5.0MPa, heat preservation and pressure for 20 minutes; heat the graphite heater on the outer layer of the heat preserv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com