Lead-free environment friendly type high density bullet and preparation method thereof

A high-density, environmentally friendly technology, used in ammunition, warheads, offensive equipment, etc., can solve the problems of low projectile strength, damage to the barrel, etc., to avoid direct friction, avoid pollution, and improve the effect of coating speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

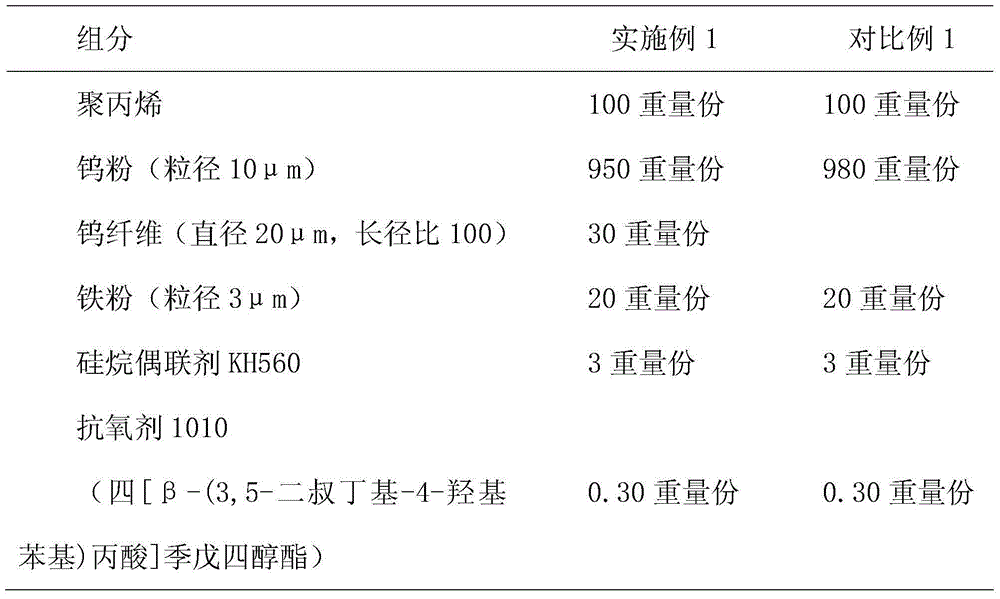

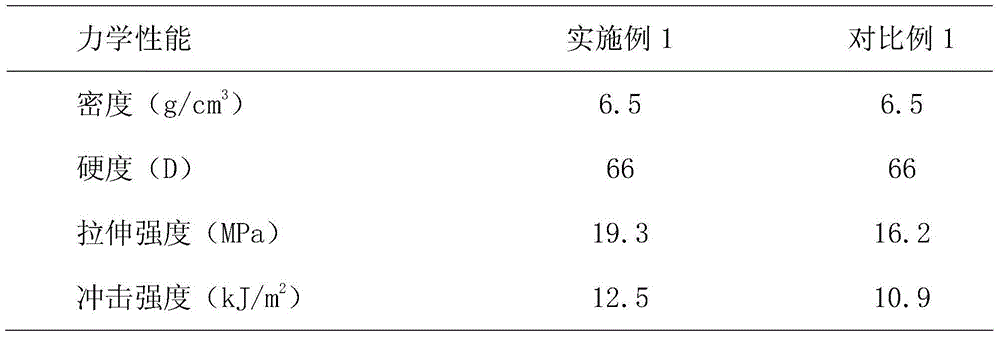

[0041] The formulation of the lead-free environment-friendly high-density bullet base material is:

[0042]

[0043] The preparation method of the lead-free environment-friendly high-density bullet comprises the steps of:

[0044] (1) Blending of ingredients: Weigh the quality of various raw materials according to the formula, and mix them evenly in a high-speed mixer to obtain a mixture.

[0045] (2) Extrusion granulation: Put the mixture into a twin-screw extruder, extrude and pelletize at 180°C to obtain injection feed granules.

[0046] (3) Injection molding: The injection feed particles are injected and molded through an injection machine at 200°C to obtain lead-free, environmentally friendly, high-density blanks.

[0047] (4) Preform shaping: Grinding the obtained lead-free environment-friendly high-density preform to remove the injection gate to obtain a preformed preform.

[0048] (5) Copper plating on the spring blank: the surface of the plastic blank is firstly ...

Embodiment 2

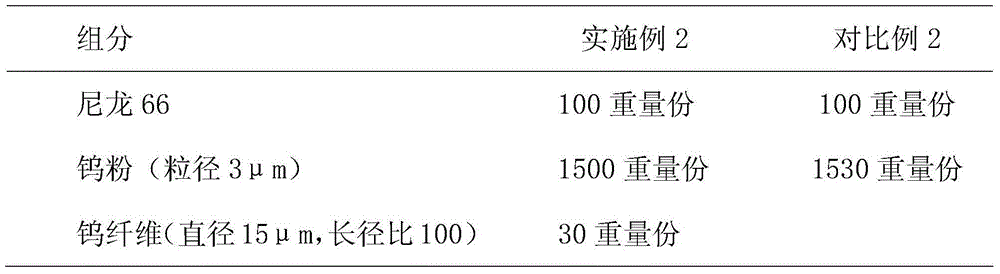

[0052] The formulation of the lead-free environment-friendly high-density bullet base material is:

[0053]

[0054]

[0055] The preparation method of the lead-free environment-friendly high-density bullet comprises the steps of:

[0056] (1) Blending of ingredients: Weigh the quality of various raw materials according to the formula, and mix them evenly in a high-speed mixer to obtain a mixture.

[0057] (2) Extrusion granulation: put the mixture into a twin-screw extruder, extrude and pelletize at 260°C to obtain injection feed granules.

[0058] (3) Injection molding: The injection feed particles are injected and molded through an injection machine at 290°C to obtain lead-free, environmentally friendly, high-density blanks.

[0059] (4) Preform shaping: Grinding the obtained lead-free environment-friendly high-density preform to remove the injection gate to obtain a preformed preform.

[0060] (5) Copper plating on the spring blank: firstly carry out chemical copper ...

Embodiment 3

[0065] The formulation of the lead-free environment-friendly high-density bullet base material is:

[0066]

[0067] The preparation method of the lead-free environment-friendly high-density bullet comprises the steps of:

[0068] (1) Blending of ingredients: Weigh the quality of various raw materials according to the formula, and mix them evenly in a high-speed mixer to obtain a mixture.

[0069] (2) Extrusion granulation: Put the mixture into a twin-screw extruder, extrude and pelletize at 180°C to obtain injection feed granules.

[0070] (3) Injection molding: The injection feed particles are injected and molded through an injection machine at 200°C to obtain lead-free, environmentally friendly, high-density blanks.

[0071] (4) Preform shaping: Grinding the obtained lead-free environment-friendly high-density preform to remove the injection gate to obtain a preformed preform.

[0072] (5) Copper plating on the spring blank: firstly carry out chemical copper plating on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com