KOH developing liquid for KMPR photoresist

A technology of developing solution and photoresist, which is applied in the field of KOH developing solution, can solve problems such as long time required for developing KMPR, development effect is not as good as its organic solvent developing solution, and influence of KMPR glue industrialized use, etc., so as to improve quality and stability , delayed adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

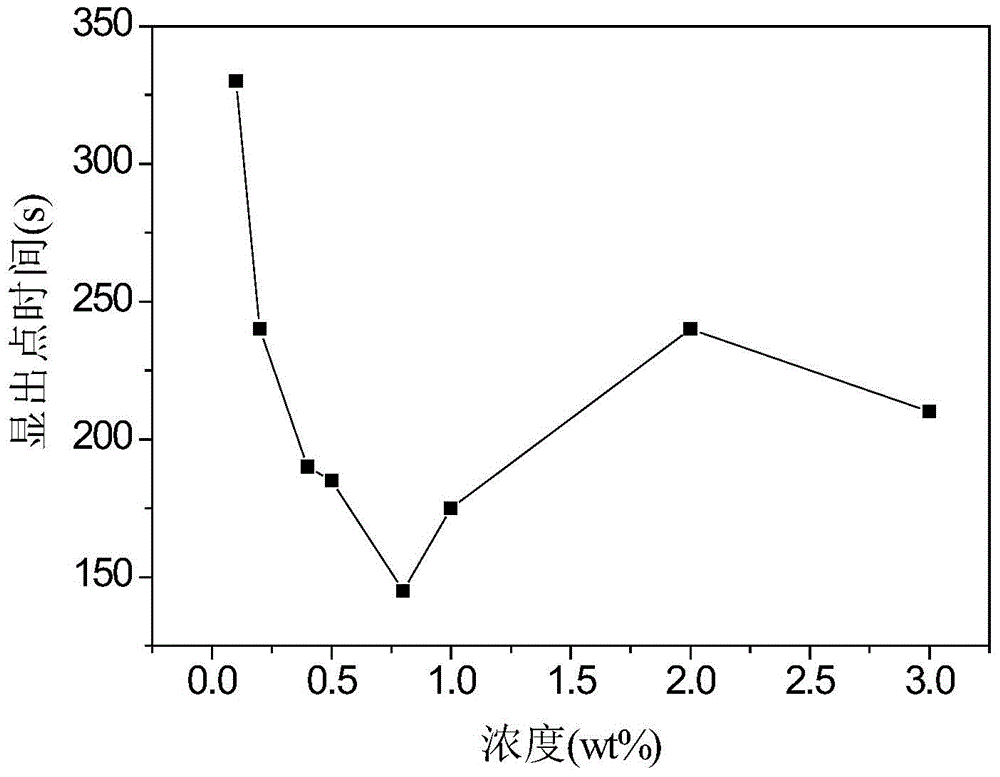

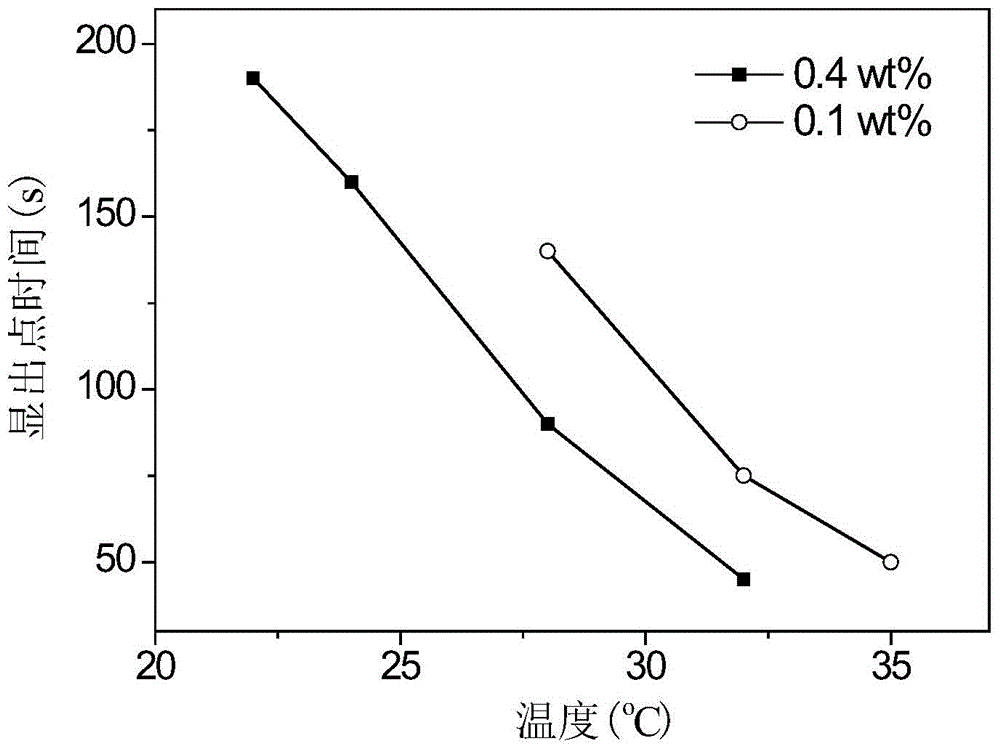

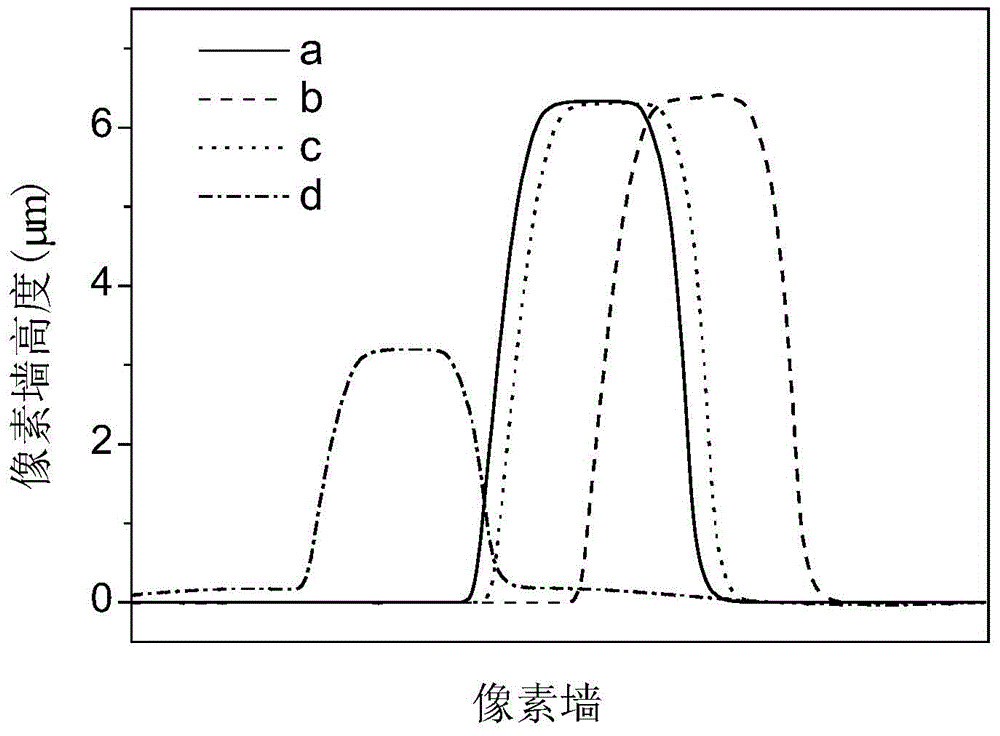

[0027] Example 1: Weigh a certain amount of KOH, dissolve it in 100mL deionized water, and shake it evenly to obtain a developer solution with a concentration of 0.1wt%. Add the obtained developer solution to the developing pool, and develop a 3-inch solution at 24°C. Substrate (side length 7.6cm), the height of the pixel wall formed by the photoresist KMPR on the substrate is 6-7μm, and the development method: shaking development.

Embodiment 2

[0028] Embodiment 2: develop under the condition of 35° C., and other conditions are the same as embodiment 1.

Embodiment 3

[0029] Example 3: Weigh a certain amount of KOH, dissolve it in 100mL of deionized water, and shake it evenly to obtain a developer solution with a concentration of 0.4wt%. The developer solution is added to the developing pool, and developed at 24°C for 3 inches Substrate (side length 7.6cm), the height of the pixel wall formed by the photoresist KMPR on the substrate is 6-7μm, and the development method: shaking development.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com