Long-acting antibacterial negative ion polypropylene material and preparation method thereof

A polypropylene material and negative ion technology, applied in the field of fiber materials, can solve the problems of poor heat resistance, low antibacterial efficiency, easy agglomeration, etc., and achieve the effect of enhancing mechanical properties and long-term antibacterial properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

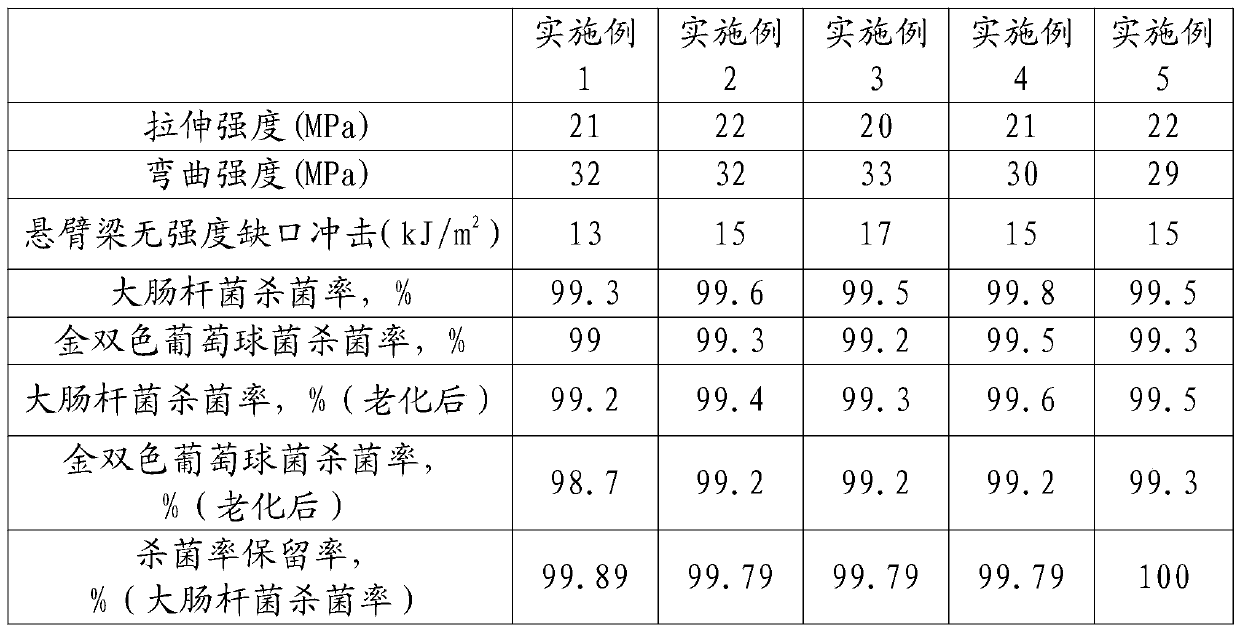

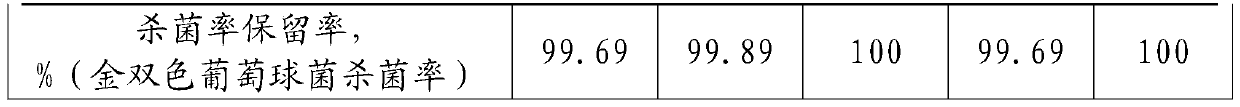

Examples

Embodiment 1

[0025] 75.8g of polypropylene, 12g of antibacterial agent filler, 10g of toughening agent vinyl elastomer (POE), antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol Add 0.2g of ester and 0.3g of tris[2,4-di-tert-butylphenyl]phosphite, 1.3g of lubricant silicone powder, and 0.4g of coupling agent polypropylene grafted maleic anhydride to the high mixer Medium-dry mixing for 8 minutes, adding the uniformly mixed raw materials into a twin-screw extruder to melt, extrude and granulate to obtain a long-acting antibacterial anion polypropylene material;

[0026] Wherein the preparation process of antimicrobial filler is as follows:

[0027] 350g of 6-aminocaproic acid and 100g of L-hydroxyproline were added to a sufficient amount of deionized water and added to the flask; 1.05mL of 85% H 3 PO 3 Catalyze, and add 350g nano-ZnO / tourmaline material, wherein ZnO / tourmaline material in ZnO / tourmaline material=1:0.3; the above reaction solution is...

Embodiment 2

[0029] 88.6-67.0g of polypropylene, 15g of antibacterial agent filler, 9g of toughening agent ethylene propylene diene rubber (EPDM), antioxidant tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propylene Acid] pentaerythritol ester 0.3g and tris [2,4-di-tert-butylphenyl] phosphite 0.3g, lubricant calcium stearate 1.2g, coupling agent silane coupling agent 0.5g each component is added to high mixing Dry-mix in the machine for 6 minutes, put the evenly mixed raw materials into the twin-screw extruder to melt, extrude and granulate to obtain a long-acting antibacterial anion polypropylene material;

[0030] Wherein the preparation process of antimicrobial filler is as follows:

[0031] 320g of 6-aminocaproic acid and 100g of L-hydroxyproline were added to a sufficient amount of deionized water and added to the flask; 1.12mL of 84% H 3 PO 3 Catalyze, and add 384g nano-ZnO / tourmaline material, wherein ZnO / tourmaline material in ZnO / tourmaline material = 1:0.4; the above reaction ...

Embodiment 3

[0033] Polypropylene 88.6-67.0g, antibacterial filler 8g, styrene-butadiene elastomer (SBS) 4g and hydrogenated styrene-butadiene-styrene elastomer (SEBS) 7g, antioxidant tetrakis [β- (3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.2g and tris[2,4-di-tert-butylphenyl]phosphite 0.6g, lubricant zinc stearate 1.4 g, coupling agent titanate coupling agent 0.3g each component is added to a high mixer and dry mixed for 7 minutes, and the uniformly mixed raw materials are added to a twin-screw extruder to melt, extrude and granulate to obtain a long-acting Antibacterial negative ion polypropylene material;

[0034] Wherein the preparation process of antimicrobial filler is as follows:

[0035] 380g of 6-aminocaproic acid and 100g of L-hydroxyproline were added to a sufficient amount of deionized water and added to the flask; 0.95mL of 85% H 3 PO 3 Catalyze, and add 304g nano-ZnO / tourmaline material, wherein ZnO in ZnO / tourmaline material: tourmaline=1:0.3; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com