Liquid metal and high-pressure gas flowing heat exchanging device and liquid metal and high-pressure gas flowing heat exchanging method

A technology of liquid metal and high-pressure gas, which can be used in cooling devices, reduction of greenhouse gases, and climate sustainability. It can solve the problems of complex flow and heat transfer characteristics of liquid lead and bismuth, helium flow and heat transfer characteristics, and less research work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

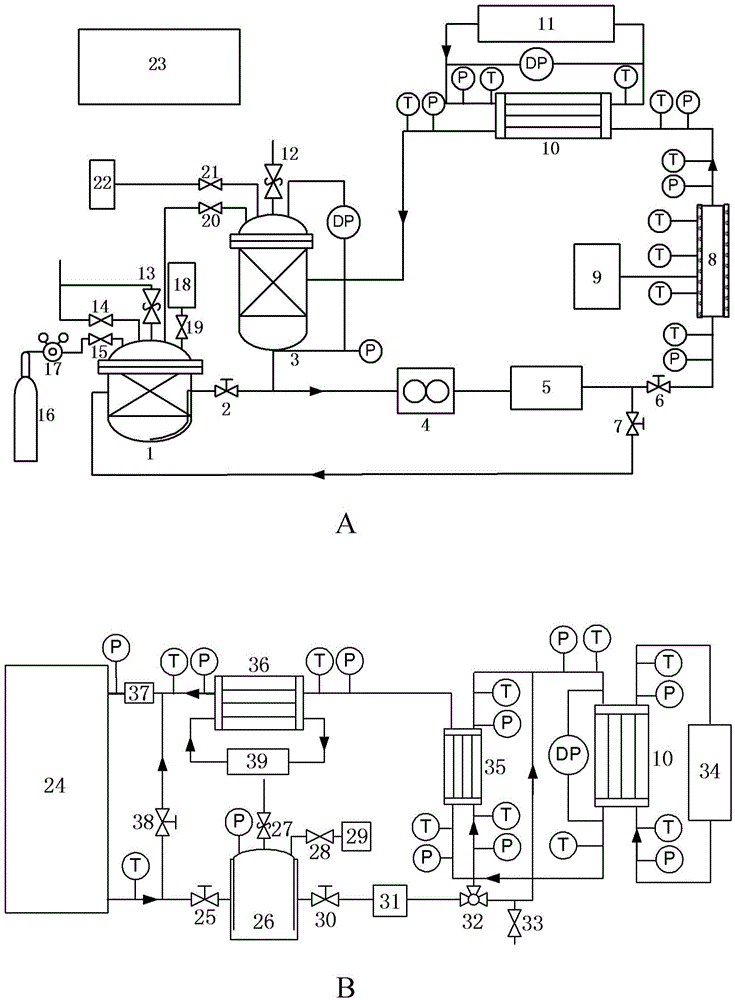

[0041] The heat exchange device of the present invention can be used to study the flow and heat transfer characteristics of high-temperature liquid lead-bismuth alloy and its flow and heat transfer characteristics with high-pressure helium gas, and can also be used for the flow and heat transfer characteristics of other high-temperature liquid metals and their flow and heat transfer characteristics with high-pressure gas Conduct research to provide detailed and reliable data for accelerator-driven subcritical systems cooled by liquid heavy metals and associated nuclear reactors.

[0042] The liquid metal and high-pressure gas flow heat exchange device of the present invention includes two parts: a liquid metal circuit and a high-pressure gas circuit; wherein:

[0043] Liquid metal circuits such as figure 1 As shown in A, it mainly consists of liquid storage tank 1, high temperature cut-off valve 2, 6, 7, working tank 3, electromagnetic flowmeter 4, electromagnetic pump 5, test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com