Plastic package device opening method

A device and component technology, applied in the field of unsealing electronic components, can solve problems such as low tolerance, and achieve the effect of improving the success rate and uniform corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] As an embodiment of the present invention, taking the LTM series plastic-encapsulated device of LINEAR company as an example, the method for unsealing the plastic-encapsulated device includes the following steps:

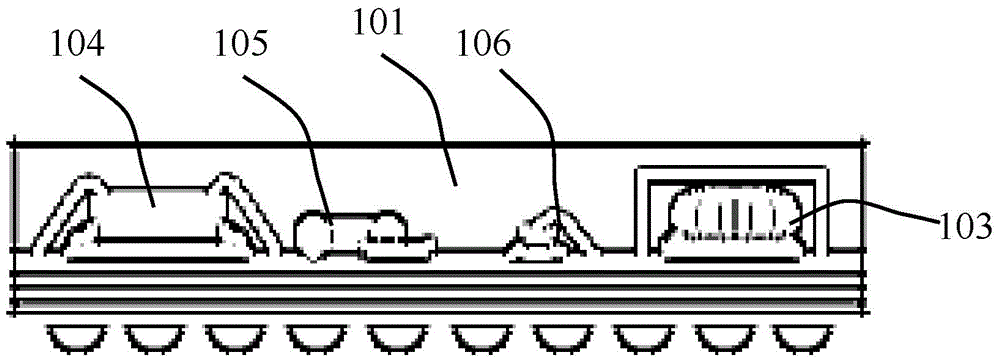

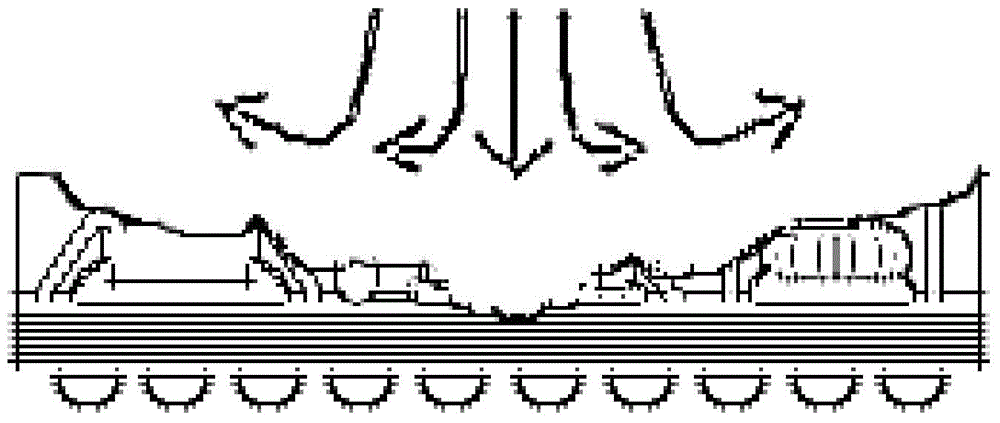

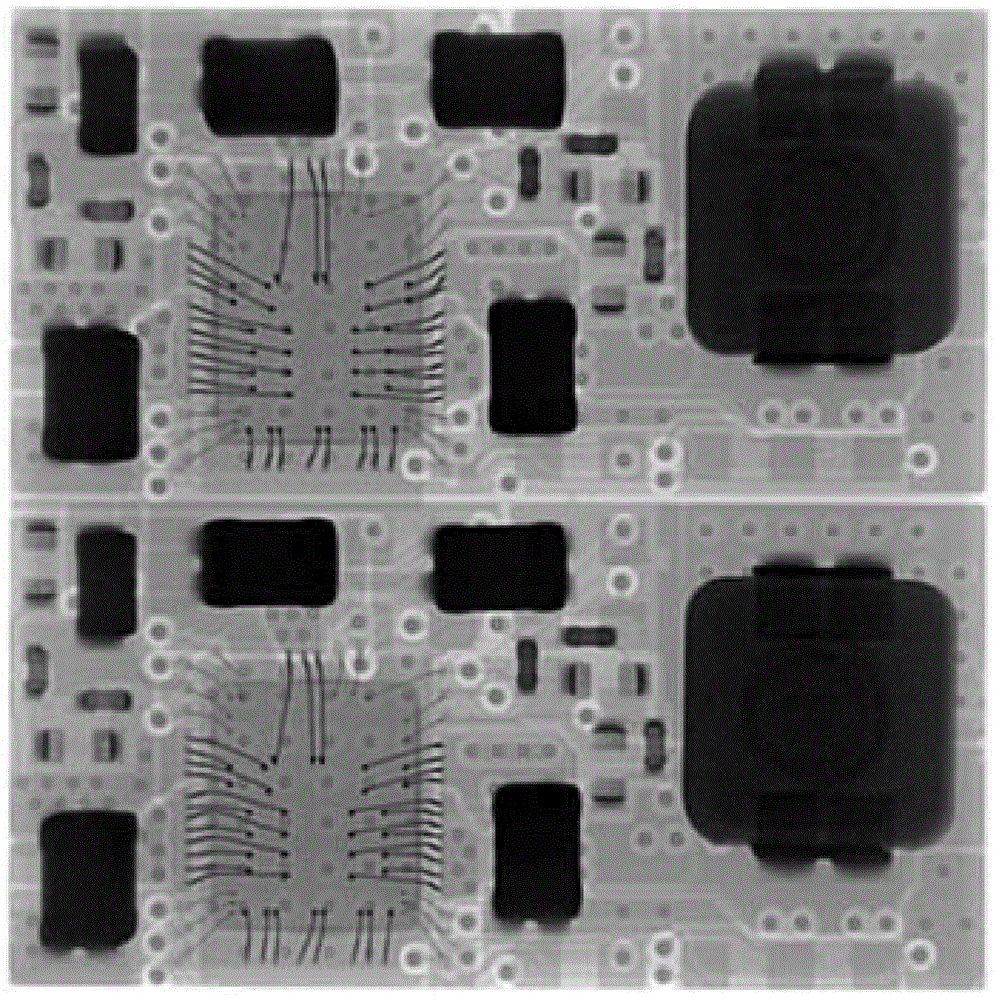

[0033] 1. Before opening the package, use the X-ray inspection method to locate the position and depth of each component and chip inside the plastic packaged device, and obtain the size, position and depth information of each component and chip inside the device, such as image 3 shown. Under normal circumstances, unpacking only needs to expose the internal chip, inductance and resistance and capacitance, so only the encapsulation material on the surface of these components and chips needs to be removed.

[0034] 2. According to the size, position and depth information of each element and chip inside the plastic-encapsulated device obtained in step 1, the plastic-encapsulated device is unsealed by laser ablation to remove the encapsulation material 101 on the...

Embodiment 2

[0043] As an embodiment of the present invention, taking the LTM series plastic-encapsulated device of LINEAR company as an example, the method for unsealing the plastic-encapsulated device includes the following steps:

[0044] 1. Before opening the package, use the X-ray inspection method to locate the position and depth of each component and chip inside the plastic packaged device, and obtain the size, position and depth information of each component and chip inside the device, such as image 3 shown. Under normal circumstances, unpacking only needs to expose the internal chip, inductance and resistance and capacitance, so only the encapsulation material on the surface of these components and chips needs to be removed.

[0045] 2. According to the size, position and depth information of each element and chip inside the plastic-encapsulated device obtained in step 1, the plastic-encapsulated device is unsealed by laser ablation to remove the encapsulation material 101 on the...

Embodiment 3

[0054] As an embodiment of the present invention, taking the LTM series plastic-encapsulated device of LINEAR company as an example, the method for unsealing the plastic-encapsulated device includes the following steps:

[0055] 1. Before opening the package, use the X-ray inspection method to locate the position and depth of each component and chip inside the plastic packaged device, and obtain the size, position and depth information of each component and chip inside the device, such as image 3 shown. Under normal circumstances, unpacking only needs to expose the internal chip, inductance and resistance and capacitance, so only the encapsulation material on the surface of these components and chips needs to be removed.

[0056] 2. According to the size, position and depth information of each element and chip inside the plastic-encapsulated device obtained in step 1, the plastic-encapsulated device is unsealed by laser ablation to remove the encapsulation material 101 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com