Control method for continuous crystal granularity of sodium thiosulfate pentahydrate

A technology of sodium thiosulfate pentahydrate and crystal particle size, applied in the direction of thiosulfate/dithionite/polythionate, etc., can solve the problem of excessively fast generation of fine crystals of sodium thiosulfate pentahydrate and product particle size. Small problems, to achieve the effect of simple structure, ensuring normal operation, and accurate sampling position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

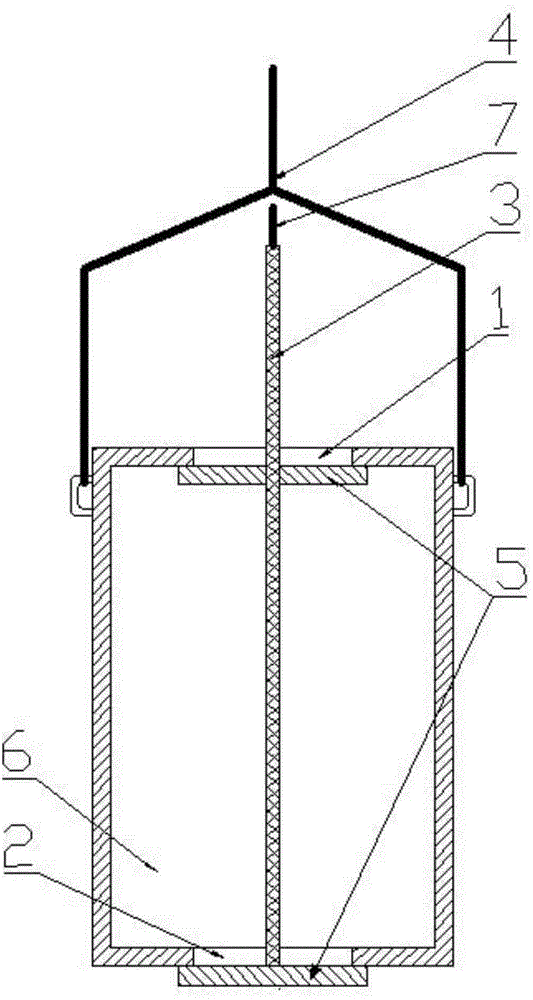

[0030] Such as figure 1 As shown, the continuous crystallization sampler of sodium thiosulfate pentahydrate comprises a storage cylinder 6, and the volume of the storage cylinder 6 is 1L; The feed port II2, the diameter of the feed port I1 and the feed port II2 is 80 mm, and the movable rod 3 that penetrates up and down and passes through the feed port I1 and the feed port II2 is provided in the storage cylinder 6. The movable rod 3 is located at the lower edge of the feed port I1 and the feed port II2 and is provided with a closing baffle 5 that can close the feed port I1 and the feed port II2. The rope 4 is connected with a lifting rope 7 on the movable rod 3 . Throughout the sampling process, the sampling position is the middle position of the suspension section, the transition section and the clear liquid section. When sampling, fix the lifting rope 4, pull the movable rod 3 upwards, and make the upper and lower two closed baffles 5 close the feed inlet I1 and feed inlet...

Embodiment 2

[0037] Such as figure 1 As shown, the continuous crystallization sampler of sodium thiosulfate pentahydrate comprises a storage cylinder 6, and the volume of the storage cylinder 6 is 1L; The feed port II2, the diameter of the feed port I1 and the feed port II2 is 90mm, and the movable rod 3 that penetrates up and down and passes through the feed port I1 and the feed port II2 is provided in the storage cylinder 6. The movable rod 3 is located at the lower edge of the feed port I1 and the feed port II2 and is provided with a closing baffle 5 that can close the feed port I1 and the feed port II2. The rope 4 is connected with a lifting rope 7 on the movable rod 3 . Throughout the sampling process, the sampling position is the middle position of the suspension section, the transition section and the clear liquid section. When sampling, fix the lifting rope 4, pull the movable rod 3 upwards, and make the upper and lower two closed baffles 5 close the feed inlet I1 and feed inlet ...

Embodiment 3

[0044] Such as figure 1 As shown, the continuous crystallization sampler of sodium thiosulfate pentahydrate comprises a storage cylinder 6, and the volume of the storage cylinder 6 is 1L; The feed port II2, the diameter of the feed port I1 and the feed port II2 is 85mm, and the movable rod 3 that penetrates up and down and passes through the feed port I1 and the feed port II2 is provided in the storage cylinder 6. The movable rod 3 is located at the lower edge of the feed port I1 and the feed port II2 and is provided with a closing baffle 5 that can close the feed port I1 and the feed port II2. The rope 4 is connected with a lifting rope 7 on the movable rod 3 . Throughout the sampling process, the sampling position is the middle position of the suspension section, the transition section and the clear liquid section. When sampling, fix the lifting rope 4, pull the movable rod 3 upwards, and make the upper and lower two closed baffles 5 close the feed inlet I1 and feed inlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com