Method for performing nitrogen biological removal on low-temperature low-carbon nitrogen ratio sewage

A low carbon-to-nitrogen ratio and biological denitrification technology, applied in the field of biological denitrification, can solve the problems of waste of air aeration energy consumption, low efficiency of denitrification and organic pollutant removal, and insignificant effect, so as to improve the quality of effluent, Improve nitrification efficiency and improve the effect of effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

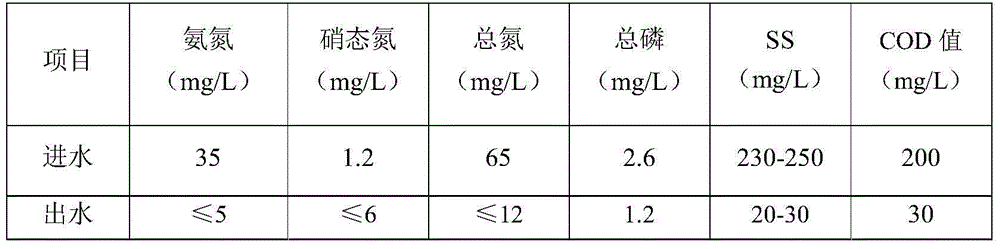

[0030] A pilot test was carried out in a sewage treatment plant in the north. The treatment scale was 100t / d, and the influent water quality was as follows: COD was 150-250mg / L, ammonia nitrogen content was 35-40mg / L, and total nitrogen content was 55-75mg / L. , the SS content is 250-300mg / L, and the pH value is 6.0-8.0.

[0031] In this embodiment, the sewage is firstly homogenized (so that the waste water is evenly mixed), and then undergoes secondary precipitation after passing through the secondary anoxic-aerobic + biofilm module reactor.

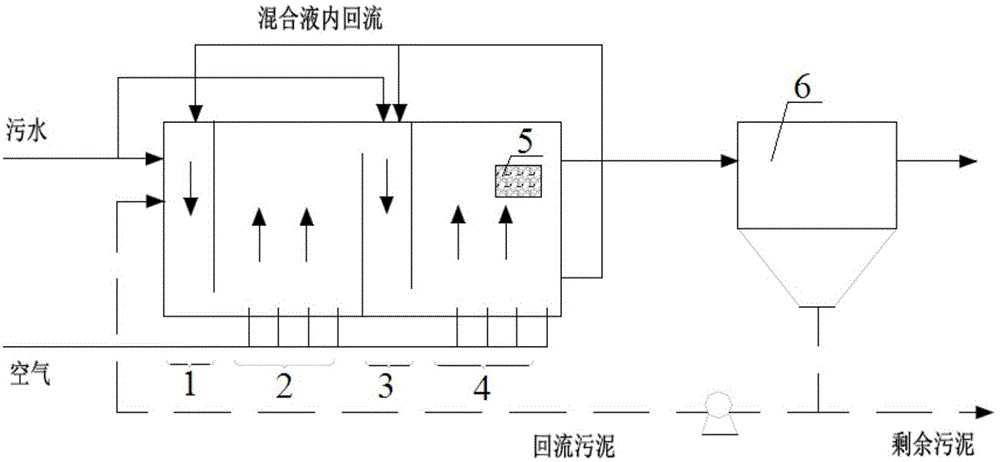

[0032] The processing system used in this embodiment is as figure 1As shown, the first-stage anoxic pool 1, the first-stage aerobic pool 2, the second-stage anoxic pool 3 and the second-stage aerobic pool 4 are sequentially connected, and the liquid surface of the second-stage aerobic pool 4 is 0.3 meters A biofilm module 5 with a thickness of 0.5m is added at the place, the coverage is 1 / 3 of the total length of the pool body, 9 / 10 of ...

Embodiment 2

[0043] A sewage plant renovation project in the north, with a treatment capacity of 2000t / d, had the main problem of total nitrogen exceeding the standard in winter before the renovation. The influent water quality is as follows: COD is 200-300mg / L, ammonia nitrogen content is 30-35mg / L, total nitrogen content is 50-70mg / L, SS content is 200-250mg / L, pH value is 6.0-8.0.

[0044] In this embodiment, before the sewage is subjected to air flotation separation, it is firstly homogenized (so that the waste water is evenly mixed) and then undergoes secondary precipitation after passing through the secondary anoxic-aerobic + biofilm module reactor.

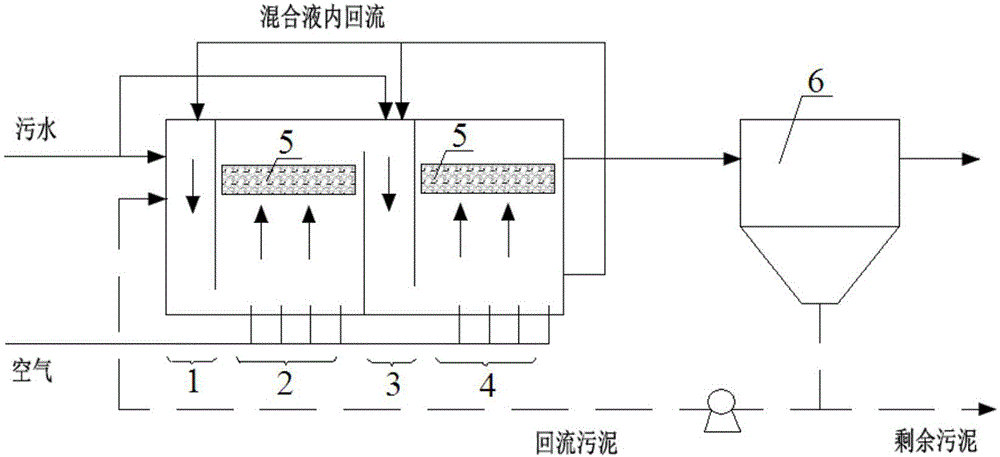

[0045] The processing system used in this embodiment is as figure 2 As shown, the first-stage anoxic pool 1, the first-stage aerobic pool 2, the second-stage anoxic pool 3 and the second-stage aerobic pool 4 are sequentially connected, and the outlet of the second-stage aerobic pool 4 is connected to the secondary sedimentation tank S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com