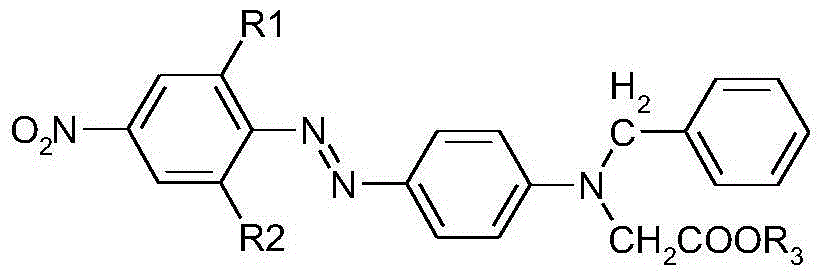

Orangered-series benzyl and ester contained azo-disperse dye as well as preparation method and application thereof

A disperse dye, benzyl-containing technology, used in azo dyes, monoazo dyes, chemical instruments and methods, etc., can solve the problems of poor washing and sublimation fastness, general item fastness, and unsuitable for dark colors. Achieve the effect of improving various fastness, bright color and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

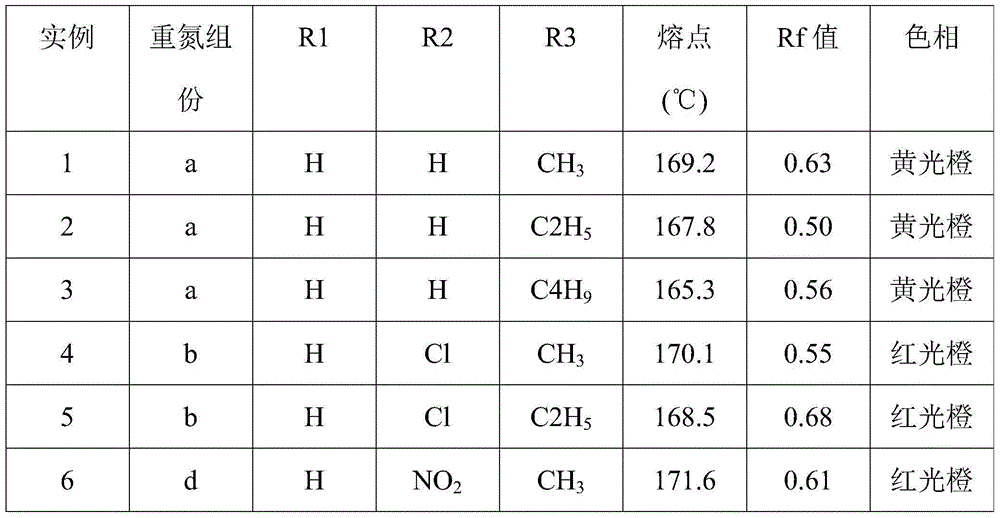

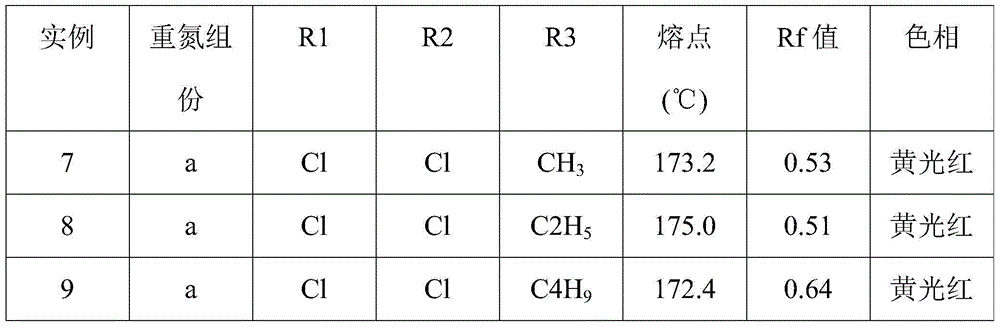

Examples

example 1

[0022] Add 13.8 grams (100%) of p-nitroaniline into 50 grams of 20% dilute hydrochloric acid, heat up to 50°C, stir for half an hour, add ice to cool to 0°C, add 7 grams (100%) of sodium nitrite aqueous solution, and keep React at 0-5°C for three hours, test with potassium iodide test paper to show blue color, add 0.1 g of urea, filter to obtain diazonium solution for use. At the same time, add 25.5 grams (100%) of N-benzyl-N-acetoxymethyl to 80 grams of 50% dilute sulfuric acid, add 150 ml of ice water, add ice and cool down to 0-5 °C to form a coupling solution . Then slowly add the prepared diazo solution into the coupling solution, and keep it below 5°C to react until the diazo component disappears, and the coupling compound is in a slight excess. Raise the temperature to 80°C and filter, wash with water until neutral, suction filter to obtain a filter cake and dry to obtain 38.1 g of disperse dye, with a yield of 94.7%.

example 2-6

[0024] In each example, the amount of the diazo component is 0.1 mole (R1 and R2 in the diazo component are shown in Table 1), and the ratio of other materials (R3 groups in the coupling component are shown in Table 1) (mol ratio) and method of operation are with example 1, and its result is:

example 2

[0025] Example 2: Obtain 38.3 grams of dyestuff, yield rate is 91.8%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com