Culture medium for producing carrageenase by using pseudoalteromonas fermentation and fermentation method

A technology of alternomonas and fermentation medium, which is applied in the field of medium for producing carrageenase by fermenting Pseudomonas carrageenan, and can solve the problem of low activity, limited application, poor stability of carrageenase, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

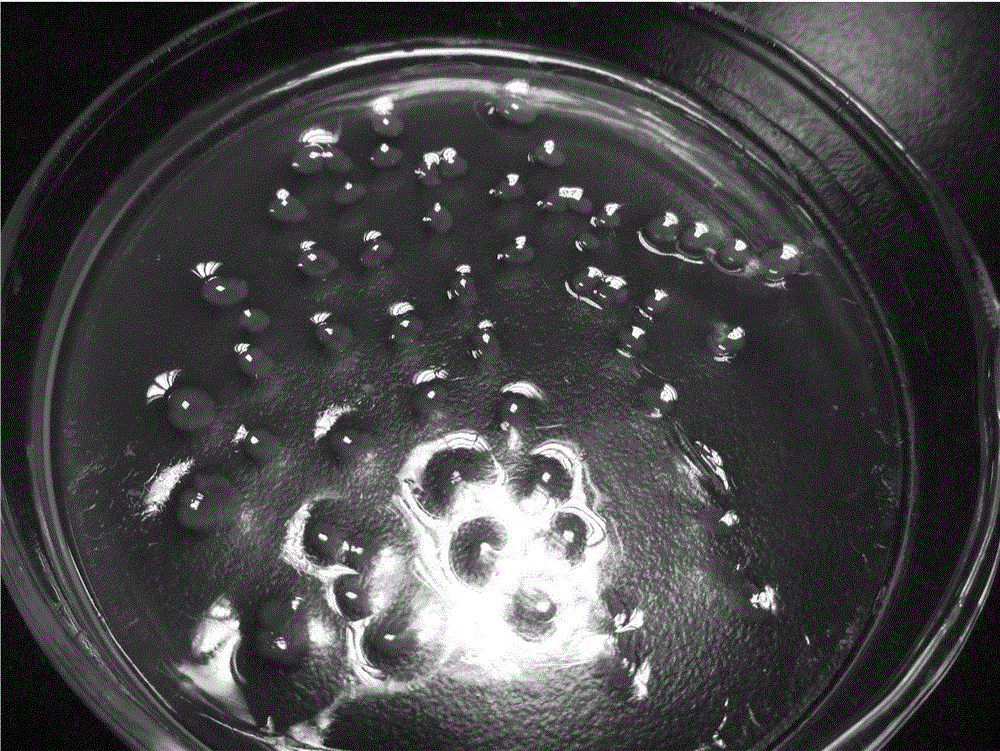

[0029] Example 1: Screening of Carrageenan Pseudoalteromonas ASY5

[0030] In the present invention, a carrageenan-eating Pseudoalteromonas ASY5 ( Pseudoalteromonas sp.ASY5) (preservation number: CICC23819), a solid medium was prepared with carrageenan as the sole carbon source, cultured at 20°C for 48 hours after inoculation, hydrolysis circles or pits formed after the degradation of carrageenan appeared on the plate, such as figure 1 shown.

Embodiment 2

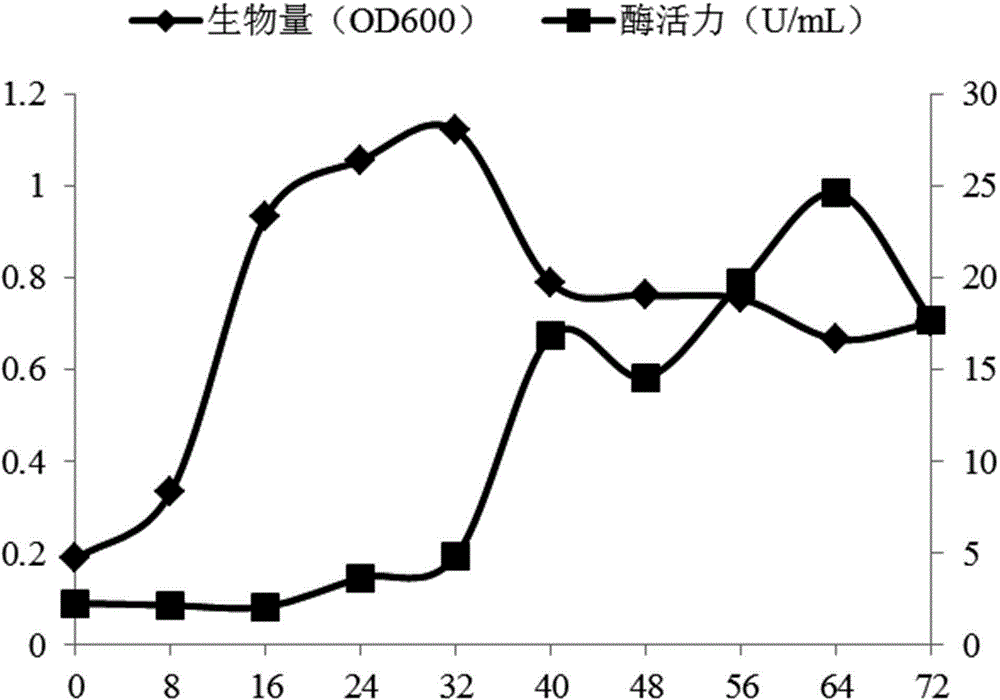

[0031] Embodiment 2: Carrageenase produced by shake flask fermentation of Carrageenan Pseudoalteromonas ASY5

[0032] (1) After thawing the glycerol tube strains stored at -20°C, they were placed on a plate containing strain activation medium, and cultured in a 20°C incubator for 24 hours to obtain activated Pseudomonas carrageenans ASY5 strains kind. The strain activation medium is: beef extract 10 g / L, tryptone 10 g / L, agar 20 g / L, NaCl 21.1 g / L, KCl 0.58 g / L, CaCl2 0.811 g / L, MgCl 2 ·6H 2 O 3.6 g / L, NaHCO 3 0.083 g / L, MgSO 4 ·7H 2 O 2.625 g / L, adjust the pH to 7.3. Sterilize at 121°C for 20 min;

[0033] (2) The cultured strains were picked from the plate and placed in a 250 mL shake flask containing 40 mL seed medium, and fermented at 20°C and 180 r / min for 24 h to obtain the shake flask seed liquid. The seed medium is: peptone 5 g / L, yeast extract 1 g / L, NaCl 30 g / L, MgSO 4 ·7H 2 O 5 g / L, KCl 1 g / L, CaCl 2 0.2 g / L, K 2 HPO 4 0.1 g / L, FeSO 4 ·7H 2 O 0.02 g...

Embodiment 3

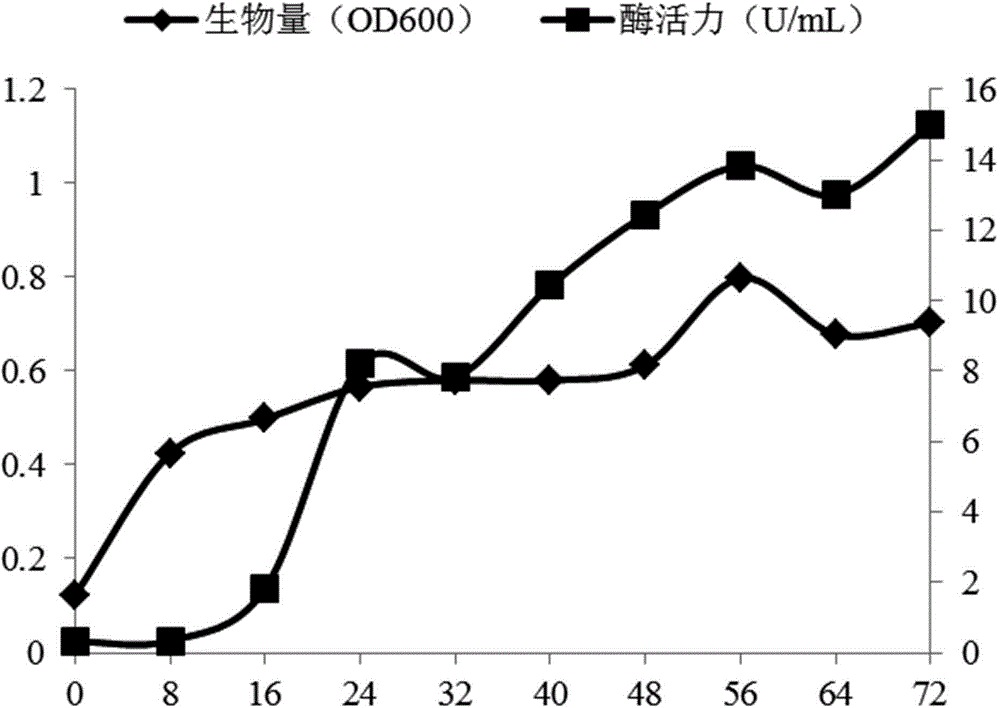

[0036] Embodiment 3: Carrageenase is produced by fermentation on tank of carrageenan-eating Pseudoalteromonas ASY5

[0037] (1) After thawing the glycerol tube strains stored at -20°C, they were placed on a plate containing strain activation medium, and cultured in a 20°C incubator for 24 hours to obtain activated Pseudomonas carrageenans ASY5 strains kind. The strain activation medium is: beef extract 10 g / L, tryptone 10 g / L, agar 20 g / L, NaCl 21.1 g / L, KCl 0.58 g / L, CaCl 2 0.811 g / L, MgCl 2 ·6H 2 O 3.6 g / L, NaHCO 3 0.083 g / L, MgSO 4 ·7H 2 O 2.625 g / L, adjust the pH to 7.3. Sterilize at 121°C for 20 min;

[0038] (2) The cultured strains were picked from the plate and placed in a 250 mL shake flask containing 40 mL seed medium, and fermented at 20°C and 180 r / min for 24 h to obtain the shake flask seed liquid. The seed medium is: beef extract 10 g / L, tryptone 10 g / L, NaCl 21.1 g / L, KCl 0.58 g / L, CaCl 2 0.811 g / L, MgCl 2 ·6H 2 O 3.6 g / L, NaHCO 3 0.083 g / L, MgSO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Enzyme activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com