Air cooling cathode, molten salt electrolyzer and electrolysis method

A cathode and air-cooling technology, applied in the field of metallurgy, can solve the problems of no magnesium precipitation and collection morphology change, poor electrolyte light transmission, poor observation effect, etc., achieve better cooling effect and improve electrolysis efficiency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Embodiment (observe liquid magnesium collection process)

[0042] The electrolysis operation is carried out by the above-mentioned molten salt electrolysis device:

[0043] Step 1, heating the electrolyte 5 and controlling its temperature at 650±10°C;

[0044] Step 2. When the temperature of the electrolyte 5 is 655°C to 660°C, the anode 4 and the air-cooled cathode are energized for electrolysis;

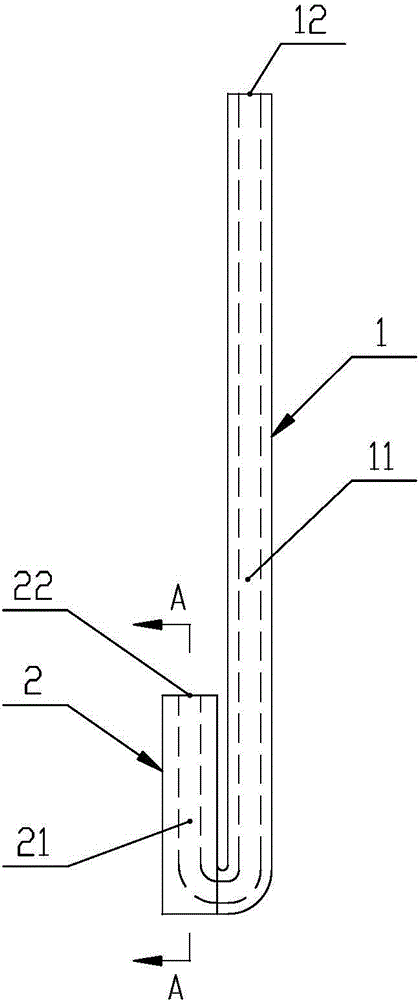

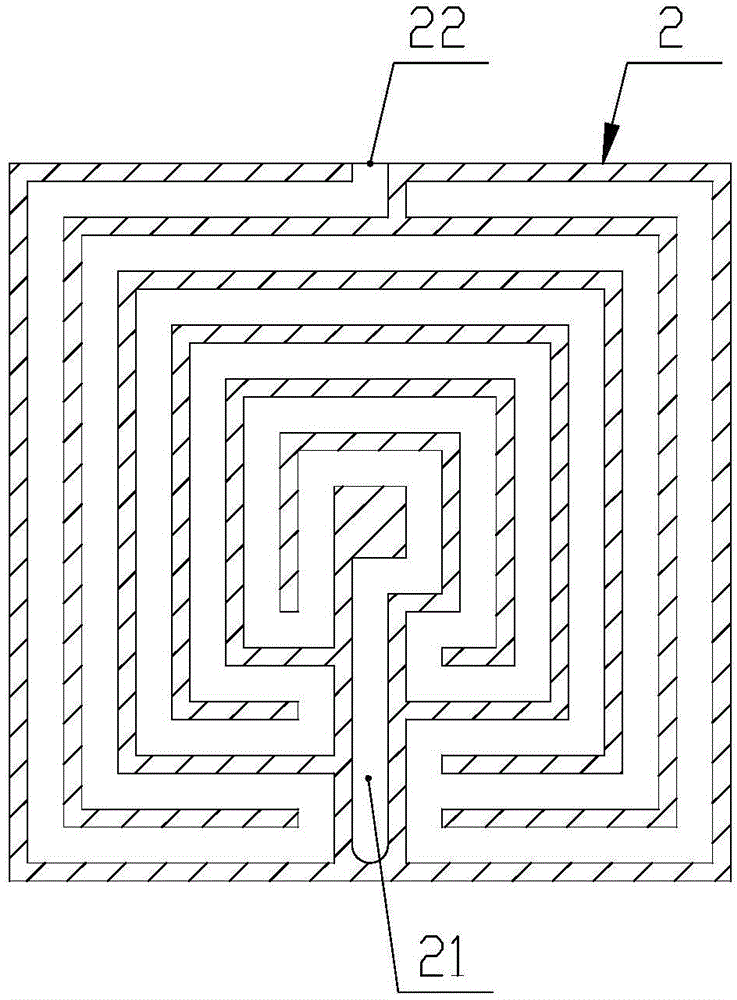

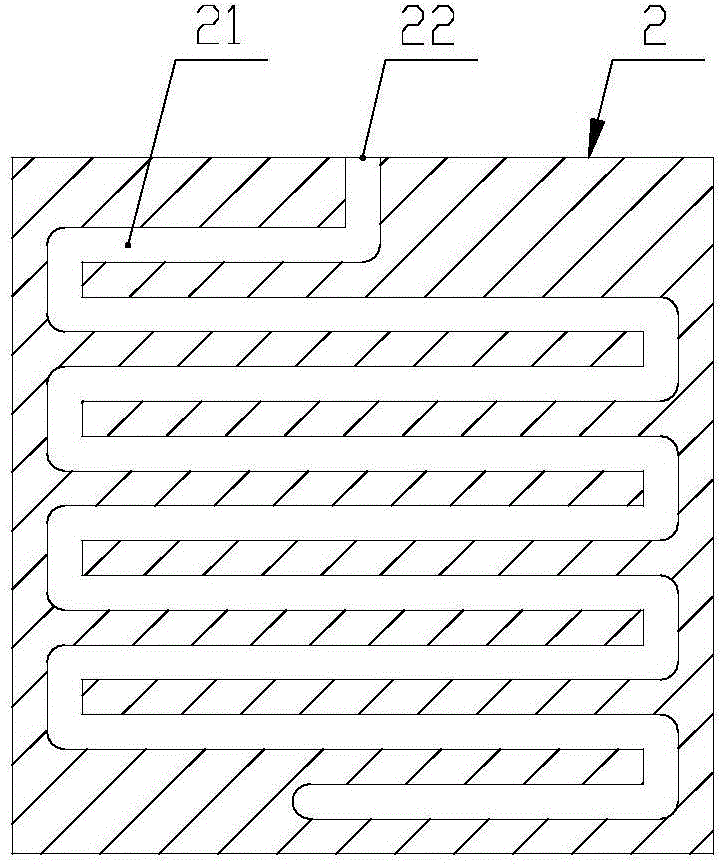

[0045] Step 3: After electrolysis for 0.5 hours, argon gas at normal temperature is introduced into the gas channel 11 of the air-cooled cathode from the cold air supply device, and the temperature of the electrolyte 5 is controlled at 645°C to 650°C through the argon gas;

[0046] Step 4, continue the electrolysis for 0.5 hours, then stop the electrolysis after power off, and obtain solid-phase metal products;

[0047] Wherein, the depth that the cathode plate 2 is submerged in the electrolyte 5 is two-thirds of the height of the cathode plate 2; 3 / h; Electrolyte 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com