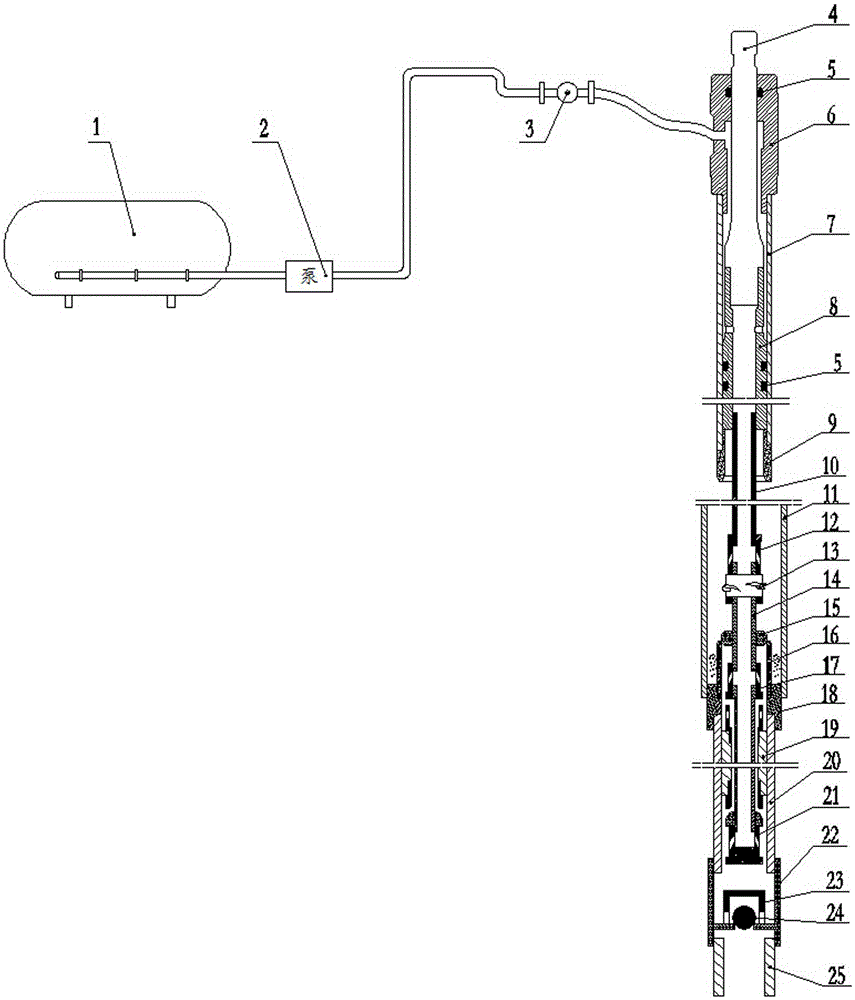

Anti-scaling pumping system for ASP flooding well

A ternary composite, anti-scaling technology, applied in wellbore/well components, pumps with flexible working elements, liquid variable capacity machinery, etc. Achieve the effect of improving wear resistance, reducing oil well failures and preventing scale deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical characteristics of the present invention, the solution of the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0024] Anti-scaling oil pumping system for three-element compound flooding wells, including dosing device, liquid injection device, oil pump, oil pipe and oil sucker rod 10 and hollow slide rod 14 arranged in the oil pipe, the upper part of the liquid injection device passes through the tee 6 It is connected with the dosing pipeline of the dosing device, the lower part is connected with the sucker rod 10 of hollow structure and the lower end is packaged with a plug 9, and a penetrating liquid injection channel is provided inside the liquid injection device; the oil well pump includes a pump barrel assembly Assemblies, plunger assembly and fixed valve assembly, the structure of the pump barrel assembly and plunger assembly ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com