Heat energy comprehensive utilization device of heat-power system with steam boiler

A thermal system and steam boiler technology, applied in steam boilers, steam generation, preheating, etc., can solve the problems of endangering the safety of boiler operation, low preheating temperature, and inability to exchange heat energy, so as to achieve full utilization of heat energy, considerable benefits, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

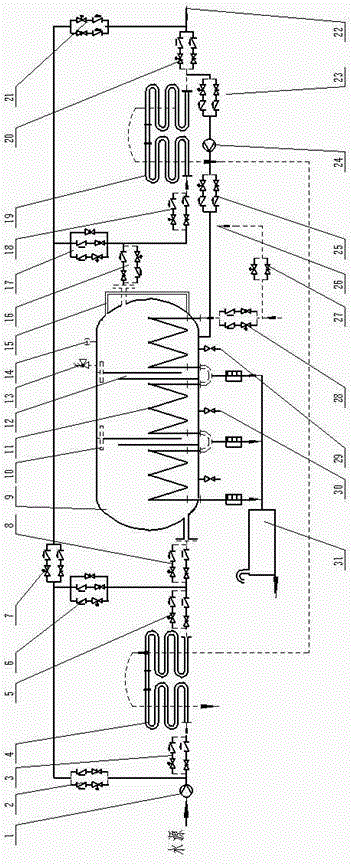

[0012] A thermal energy comprehensive utilization device of a thermal system containing a steam boiler, including a feed water pump and a boiler water inlet connected to the boiler, and the pipeline between the feed water pump and the boiler water inlet is sequentially provided with a low-temperature smoke filter for dust removal. The primary economizer for heat exchange with flue gas, the secondary economizer for heat exchange with the high-temperature flue gas that has just left the steam boiler furnace, on the pipeline between the primary economizer and the secondary economizer There is a sub-bin isobaric preheater, and the sub-bin isobaric preheater is equipped with a pressure-bearing shell, and the two ends of the pressure-bearing shell are respectively provided with a water inlet connected with the first-level economizer and a water inlet connected with the second-level economizer. For the water outlet where the economizer is connected, several stages of preheating chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com