Wavelength conversion device with a cooling structure baseplate and light emitting device

A technology of wavelength conversion device and cooling structure, which is applied to cooling/heating devices of lighting devices, lighting devices, projection devices, etc., can solve the problems of reduced efficiency of wavelength conversion materials and affecting the reliability of wavelength conversion materials, and achieves simple structure, Enhances air convection and ensures efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

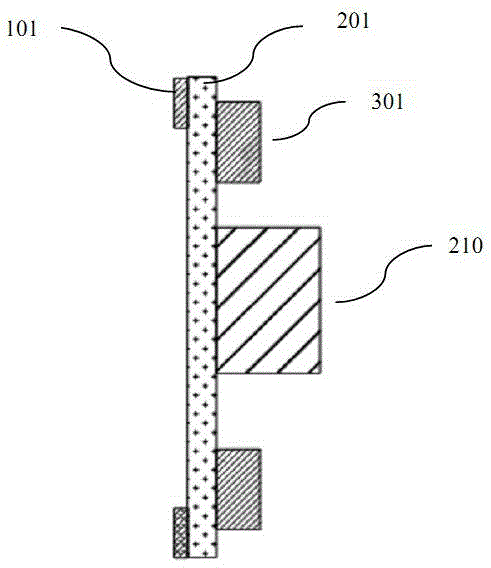

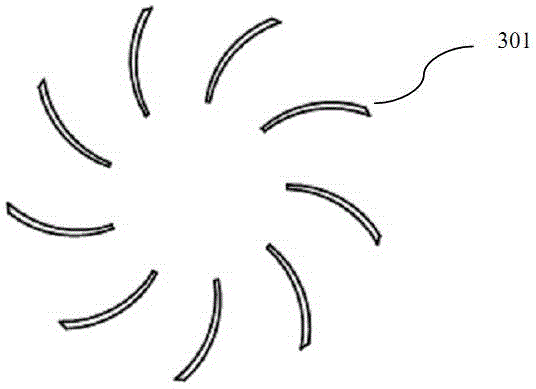

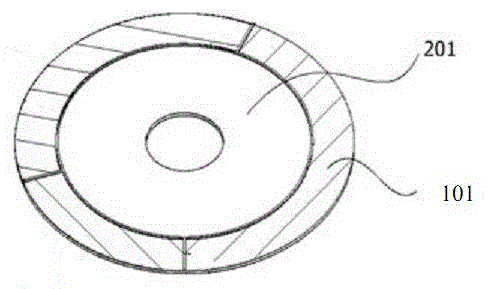

[0016] figure 1 , 2 , 3 shows Embodiment 1 of the present invention. The components of the light-emitting device include (1) an aluminum reflective substrate 201 with a thickness of 0.7mm and a silver-plated high-reflection film on the front, (2) an airflow disturbance structure 301 made of fan blade-shaped materials with a thickness of 0.5mm, (3) The driving device 210, (4) The wavelength conversion material sheet 101 composed of red, yellow and green phosphors mixed with silica gel.

[0017] The material in the shape of the fan blade in the example is connected to the back of the reflective aluminum substrate by means of pasting / welding. The material in the shape of the fan blade can be metal or plastic, etc., and is made by stamping or other processing techniques. The front side of the aluminum reflective substrate is silver-plated with a metal high-reflection film layer.

[0018] When the driving device drives the light-emitting device to rotate at high speed, the wavel...

Embodiment 2

[0020] Figure 4 , 5 Shown is Example 2 of the present invention. The components of the light-emitting device include (1) an aluminum reflective substrate 202 with a thickness of 1.2mm and a silver-coated high-reflection film layer on one side. ) a driving device 210, (4) a wavelength conversion material sheet 102 formed by mixing yellow and green phosphors and silica gel.

[0021] The aluminum reflective substrate in the example has a total thickness of 1.2mm. A fan blade-shaped airflow disturbance structure is formed on the back of the aluminum reflective substrate by machining and other methods. The thickness of the plane part of the aluminum reflective substrate is 0.7mm. The thickness of the part is 0.5mm, and the front of the reflective substrate of the aluminum sheet is coated with an aluminum metal high-reflection film layer.

[0022] When the driving device drives the light-emitting device to rotate at a high speed, the wavelength conversion material layer coated o...

Embodiment 3

[0024] Figure 6 , 7 Shown is Example 3 of the present invention. The components of the light emitting device include (1) a reflective substrate 203 made of ceramic material with a thickness of 1mm, (2) a copper heat dissipation substrate 401 with a total thickness of 1mm, the plane part of the heat dissipation substrate is 0.5mm, and the thickness of the fan blade shape part is 0.5mm , (3) A wavelength conversion material sheet 103 made of yellow and green phosphors mixed with an inorganic bonding material, (4) A driving device 210 .

[0025] The copper heat dissipation substrate is directly formed into an airflow disturbance structure with a 0.5mm thick plane part and a 0.5mm thick fan blade shape by machining, and the ceramic reflective substrate and the copper heat dissipation substrate are bonded by organic / inorganic glue Or fixed by welding.

[0026] When the driving device drives the light-emitting device to rotate at high speed, the wavelength conversion material sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com