TMX320F28335 floating point DSP (Digital Signal Processor) based two-shaft photoelectric tracking system

A technology of TMX320F28335 and photoelectric tracking system, applied in the direction of using feedback control, etc., can solve the problems of low tracking accuracy, inconvenient installation, disassembly and maintenance, etc., and achieve the effect of improved tracking accuracy, light equipment, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

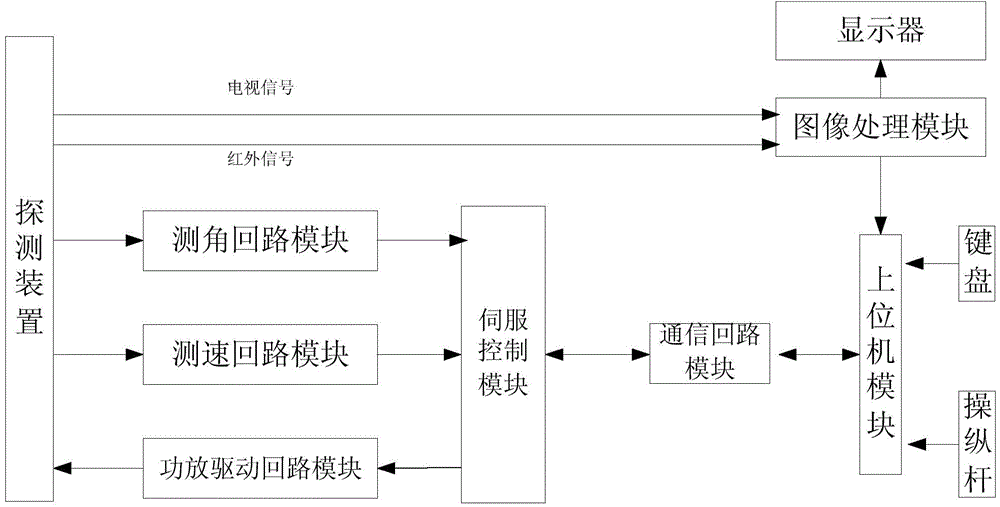

[0040] Specific implementation mode one: combine figure 1 Describe this embodiment, a two-axis photoelectric tracking system based on TMX320F28335 floating-point DSP described in this embodiment, the two-axis photoelectric tracking system includes a detection device, a servo control module, an angle measurement loop module, a speed measurement loop module, a dynamic put drive circuit module, communication circuit module, host computer module and image processing module;

[0041] The detection device is used to use the photoelectric encoder to measure the angle of the pitch axis and the azimuth axis, and use two single-axis fiber optic gyroscopes to measure the angular rate of the azimuth axis and the pitch axis direction respectively; the two single-axis fiber optic gyroscopes are arranged orthogonally ;Use infrared or camera device to collect the image information of the characteristic target; it is also used to receive the driving amount of the pitch axis and the driving amo...

specific Embodiment approach 2

[0056] Specific embodiment two: this embodiment is a further limitation of a two-axis photoelectric tracking system based on TMX320F28335 floating-point DSP described in specific embodiment one,

[0057] The digital PID adjustment algorithm is used in the control of the servo control module. PID adjustment is a control technology with mature technology and wide application in the continuous control system, so it is widely used in various control systems. It is characterized by the formation of a typical structure, convenient parameter setting and adjustment, flexible structure modification, and strong adaptability;

[0058] The output of the controlled quantity of described servo controller module adopts digital PID regulator to regulate, and the mathematical model of described PID regulator is:

[0059] u ( t ) = K p e ( t ...

specific Embodiment approach 3

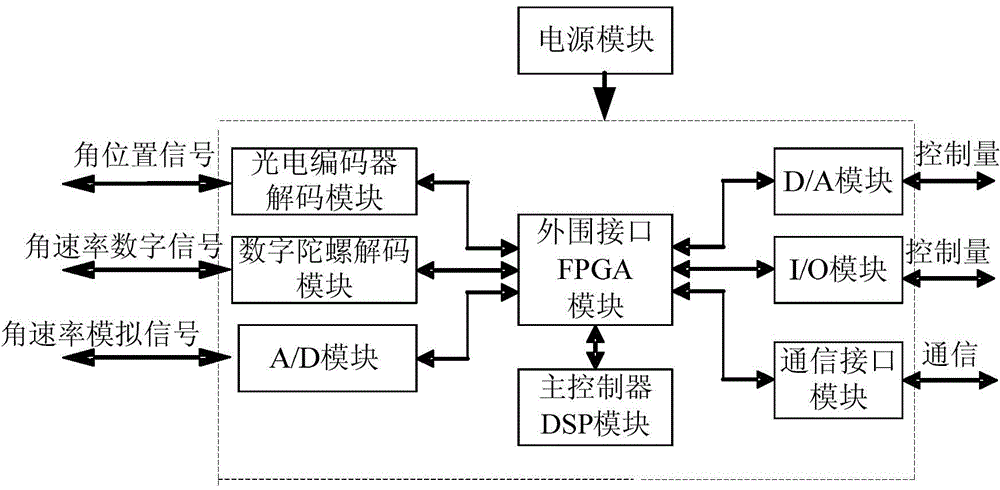

[0069] Specific implementation mode three: combination figure 2 This embodiment is described. This embodiment is a further limitation of the two-axis photoelectric tracking system based on TMX320F28335 floating-point DSP described in Embodiment 1. The servo control module includes a main controller DSP module and a peripheral interface FPGA module , power supply module, photoelectric encoder decoding module, digital gyro decoding module, analog gyro A / D sampling module, D / A module and I / O module; the main controller DSP module is TMX320F28335 floating-point DSP;

[0070] The photoelectric encoder decoding module, digital gyroscope decoding module, analog gyroscope A / D sampling module, D / A module and I / O module perform serial communication with the peripheral interface FPGA module at the same time, and the peripheral interface FPGA module communicates with the main controller DSP module through Parallel bus communication;

[0071] The power module provides working power for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com