Method for improving optical performance of active matrix miniature LED (light-emitting diode) display

A LED display and active matrix technology, which is applied in the field of improving the optical performance of active matrix micro-LED displays, can solve the problems affecting the optical contrast and image quality of the display, light crosstalk, and light extraction efficiency, etc., so as to reduce the optical crosstalk phenomenon, Increase light extraction efficiency and solve the effect of light dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

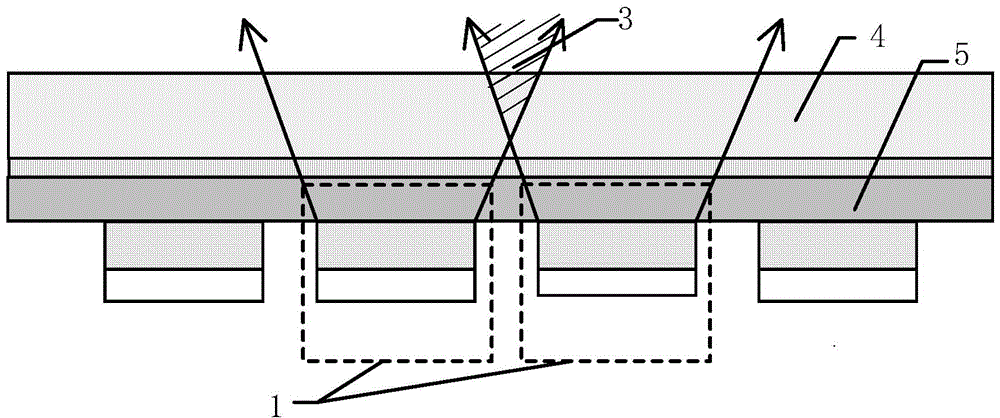

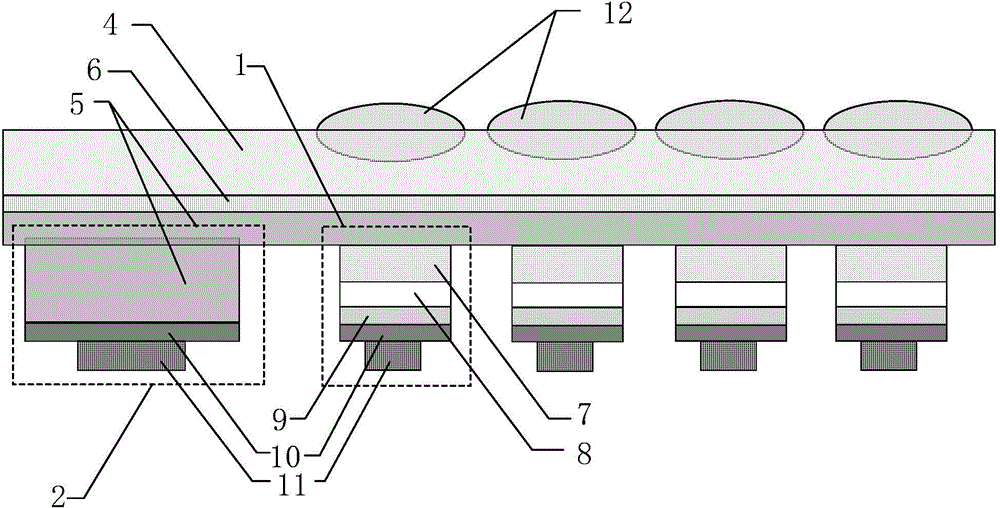

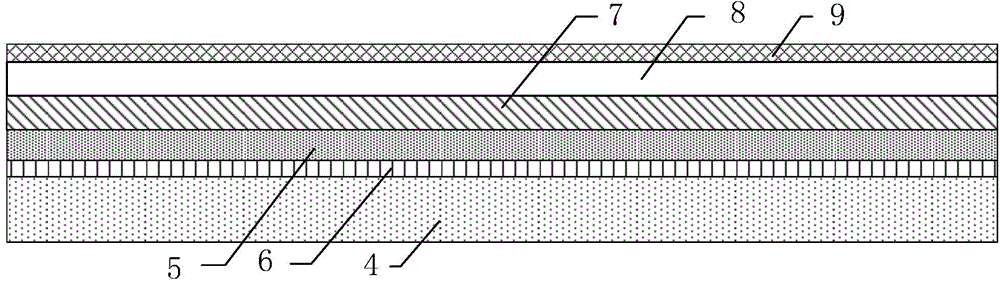

[0032] The present invention will be further described below with reference to the accompanying drawings and examples.

[0033] Such as Figure 1-4 shown.

[0034] A method for improving the optical performance of an active matrix micro-LED display, comprising the steps of:

[0035] 1) On a transparent sapphire substrate, epitaxially grow a lattice buffer layer, an N layer, a multiple quantum well (MQW), a P layer, and a current spreading layer in sequence to form an LED epitaxial wafer; the LED epitaxial wafer includes but is not limited to the following epitaxial wafers: Chip type: GaN-based LED blue epitaxial wafer, GaN-based blue-green epitaxial wafer, AlGaInP-based epitaxial wafer, etc.; the current spreading layer includes but is not limited to the following transparent or translucent conductive film materials: indium tin oxide (ITO), Nickel-gold composite layer (Ni / Au), doped zinc oxide (AZO), etc.;

[0036] 2) Sequentially adopt photolithography and dry etching proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com