Foamable oil-in-water emulsified oil or fat composition

An oil-in-water, emulsified oil technology, applied in the direction of edible oil/fat, edible oil/fat phase, dairy products, etc., can solve the problem of easy solidification of cream, and achieve the effect of not easy to solidify and good mouth solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

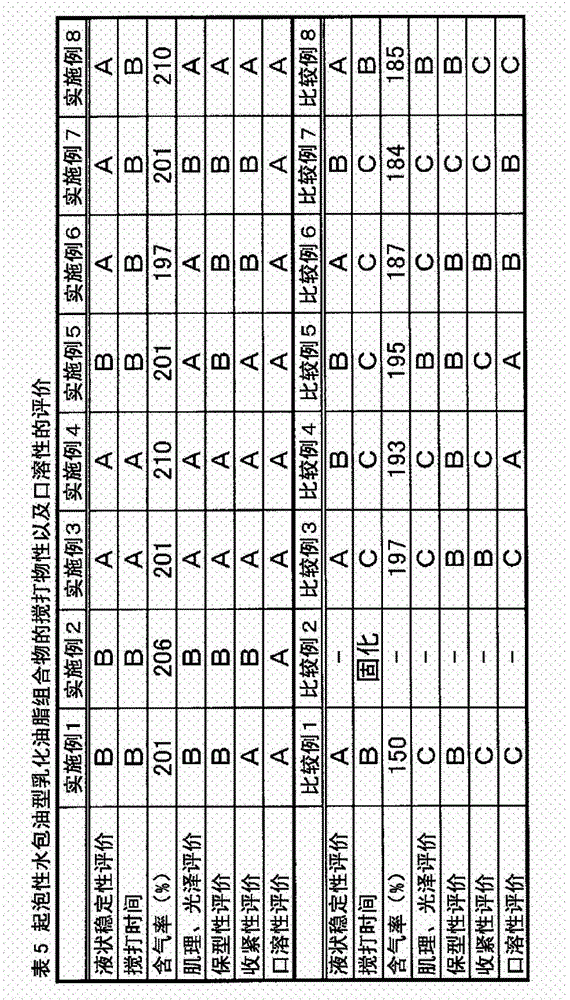

Examples

Embodiment

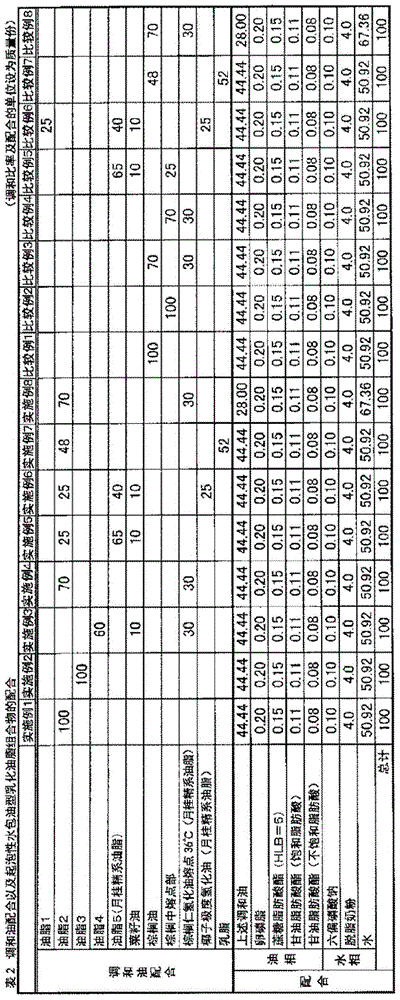

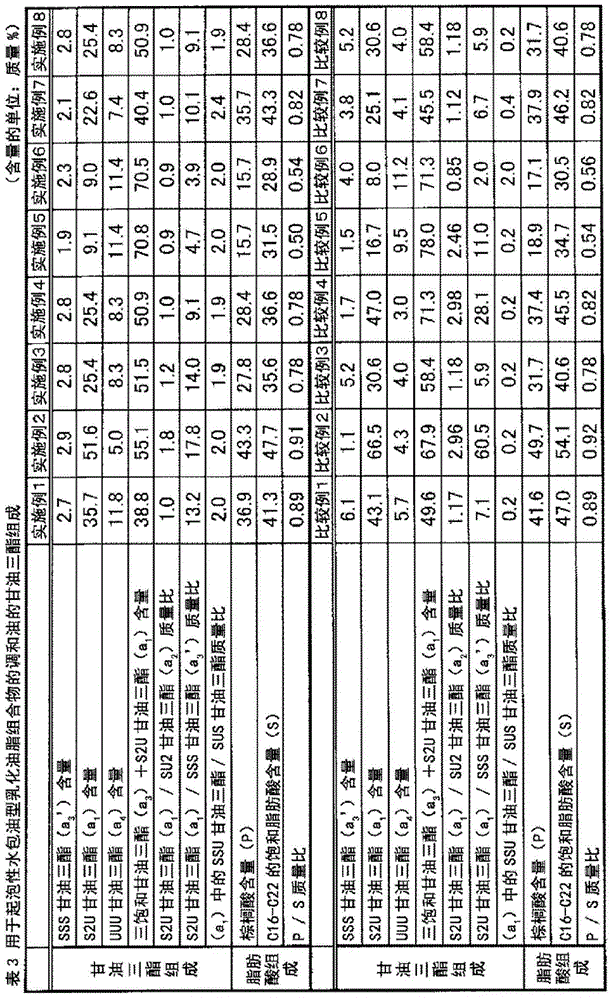

[0047] Hereinafter, examples and comparative examples are shown, and the present invention will be described in more detail. It should be noted that the present invention is not limited by these examples.

[0048] Since five kinds of fats and oils were prepared before producing the examples, the production examples of the fats and oils will be described first.

manufacture example 1

[0050] After heating 100 parts by weight of deacidified palm oil (iodine value 52) to 90°C to melt it, 0.2 parts by weight of sodium methylate was added to the liquid palm oil, and then the liquid palm oil was The oil was stirred under reduced pressure for 30 minutes. Next, after the palm oil was naturally cooled and washed with water, 2 parts by weight of white clay (white clay is white clay in Japanese) was added to the palm oil, and then the palm oil was stirred at 90° C. under reduced pressure for 30 minutes. Decolorization was carried out, and fats and oils 1 were obtained by further deodorizing at 250° C. for 1 hour.

manufacture example 2

[0052] The decolorized oil and fat obtained in Production Example 1 was heated to 70° C. to melt, and then stirred while adjusting the temperature of the oil and fat to 37° C. to precipitate crystals. After performing the crystallization treatment for 12 hours, the fats and oils were introduced into a pressing press and pressed at a pressure of 3 MPa to obtain a liquid part at a yield of 83%. Then, this liquid part was deodorized at 250 degreeC for 1 hour, and fats and oils 2 were obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com